Abstract

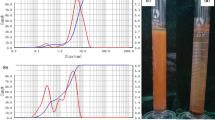

Cold spray deposition is employed to manufacture binder-free Nd2Fe14B permanent magnets. Millimeter thick deposits can be fabricated in seconds on substrates such as glass or copper. The Nd2Fe14B particles appear to partially embed in the substrate and interlock with one another, building up a dense layer that is consolidated by subsequent impacts. The impact and subsequent heating of the particles leads to formation of a magnetically soft phase that significantly reduces coercivity, X-ray diffraction identifies it as Fe. This can be mitigated by reducing gas velocity and temperature, leading to a partial retention of magnetic properties.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available upon reasonable request to corresponding author.

References

J.M.D. Coey, Permanent magnet applications. J. Magn. Magn. Mater. 248(3), 441–456 (2002)

H. Polinder, F.F.A. van der Pijl, G. de Vilder, P.J. Tavner, Comparison of direct-drive and geared generator concepts for wind turbines. IEEE Trans. Energy Convers. 21(3), 725–733 (2006)

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S.G. Sankar, J.P. Liu, Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv. Mater. 23(7), 821–842 (2011)

D. Brown, B.-M. Ma, Z. Chen, Developments in the processing and properties of NdFeb-type permanent magnets. J. Magn. Magn. Mater. 248(3), 432–440 (2002)

V. Popov, A. Koptyug, I. Radulov, F. Maccari, G. Muller, Prospects of additive manufacturing of rare-earth and non-rare-earth permanent magnets. Procedia Manuf. 21, 100–108 (2018)

L. Li et al., Big area additive manufacturing of high performance bonded NdFeB magnets. Sci. Rep. 6, 36212 (2016)

J. Jaćimović et al., Net shape 3D printed NdFeB permanent magnet. Adv. Eng. Mater. 19(8), 1700098 (2017)

C.V. Mikler et al., Laser additive manufacturing of magnetic materials. JOM 69(3), 532–543 (2017)

C. Huber et al., 3D printing of polymer-bonded rare-earth magnets with a variable magnetic compound fraction for a predefined stray field. Sci. Rep. 7(1), 9419 (2017)

J. Cui et al., Manufacturing processes for permanent magnets: part II—bonding and emerging methods. JOM (2022). https://doi.org/10.1007/s11837-022-05188-1

M. Hassani-Gangaraj, D. Veysset, V.K. Champagne, K.A. Nelson, C.A. Schuh, Adiabatic shear instability is not necessary for adhesion in cold spray. Acta Mater. 158, 430–439 (2018)

S. Yin et al., Cold spray additive manufacturing and repair: fundamentals and applications. Addit. Manuf. 21, 628–650 (2018)

A.A. Baker et al., Cold spray deposition of thermoelectric materials. JOM 72(8), 2853–2859 (2020)

P.C. King, S.H. Zahiri, M.Z. Jahedi, Rare earth/metal composite formation by cold spray. J. Therm. Spray Technol. 17(2), 221–227 (2008)

J.-M. Lamarre, F. Bernier, Permanent magnets produced by cold spray additive manufacturing for electric engines. J. Therm. Spray Technol. 28(7), 1709–1717 (2019)

S. Sugimoto, T. Maeda, R. Kobayashi, J. Akedo, M. Lebedev, K. Inomata, Magnetic properties of Sm-Fe-N thick film magnets prepared by the aerosol deposition method. IEEE Trans. Magn. 39(5), 2986–2988 (2003)

T. Maki, S. Sugimoto, T. Kagotani, K. Inomata, J. Akedo, Microstructures and magnetic properties of Sm-Fe-N thick films produced by the aerosol deposition method. Mater. Trans. 45(2), 369–372 (2004)

S. Sugimoto, T. Maki, T. Kagotani, J. Akedo, K. Inomata, Effect of applied field during aerosol deposition on the anisotropy of Sm–Fe–N thick films. J. Magn. Magn. Mater. 290–291, 1202–1205 (2005)

C. Prescher, V.B. Prakapenka, DIOPTAS: a program for reduction of two-dimensional X-ray diffraction data and data exploration. High Press. Res. 3(3), 223 (2015)

B.H. Toby, R.B. Von Dreele, GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 46(2), 544–549 (2013)

H. Assadi, F. Gärtner, T. Klassen, H. Kreye, Comment on ‘Adiabatic shear instability is not necessary for adhesion in cold spray.’ Scr. Mater. 162, 512–514 (2019)

F. Gärtner, T. Stoltenhoff, T. Schmidt, H. Kreye, The cold spray process and its potential for industrial applications. J. Therm. Spray Technol. 15(2), 223–232 (2006)

T. Schmidt, F. Gärtner, H. Assadi, H. Kreye, Development of a generalized parameter window for cold spray deposition. Acta Mater. 54(3), 729–742 (2006)

Acknowledgments

Funding for this project was through the Office of Technology Transition’s Technology Commercialization Fund (TCF). This article has been authored by Lawrence Livermore National Security, LLC under Contract No. DE-AC52-07NA27344 with the U.S. Department of Energy. Accordingly, the United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this article or allow others to do so, for United States Government purposes.

Funding

This work was funded by Office of Technology Transitions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baker, A.A., Thuss, R.C., Maich, A.A. et al. Binder-free cold spray deposition of NdFeB permanent magnets. MRS Communications 13, 561–566 (2023). https://doi.org/10.1557/s43579-023-00382-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00382-x