Abstract

The orientational dependence of Poisson’s ratio ν in tetragonal single crystalline γ-TiAl was calculated based on previously measured single crystal elastic constants. Depending on the orientation of the applied stress, ν can be quite isotropic or highly anisotropic when the transverse direction varies. For example, when the stress axis is along the [001] direction, the resulting Poisson’s ratio is a constant independent of the transverse direction; when the stress tensile axis is perpendicular to the \(\left(\overline{1 }01\right)\) crystallographic plane, ν is highly anisotropic, varying from a slightly negative value to more than 0.40.

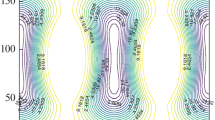

Graphical abstract

Orientational dependence of Poisson’s ratio ν in γ-TiAl single crystal for a [110] tensile direction at \(T=298 K\). θ is the angle between the [001] crystal axis and the transverse direction.

Similar content being viewed by others

Data availability

All data generated during the current study are available from the corresponding author on reasonable request.

References

X. Wu, Review of alloy and process development of TiAl alloys. Intermetallics 14, 1114–1122 (2006). https://doi.org/10.1016/j.intermet.2005.10.019

H. Clemens, S. Mayer, Intermetallic titanium aluminides in aerospace applications—processing, microstructure and properties. Mater. High Temp. 33, 560–570 (2016). https://doi.org/10.1080/09603409.2016.1163792

T. Tetsui, K. Shindo, S. Kobayashi, M. Takeyama, A newly developed hot worked TiAl alloy for blades and structural components. Scr. Mater. 47(6), 399–403 (2002). https://doi.org/10.1016/S1359-6462(02)00158-6

B.P. Bewlay, S. Nag, A. Suzuki, M.J. Weimer, TiAl alloys in commercial aircraft engines. Mater. High Temp. 33, 549–559 (2016). https://doi.org/10.1080/09603409.2016.1183068

B.P. Bewlay, M.J. Weimer, T. Kelly, A. Suzuki, P. Subramanian, The Science, technology, and implementation of TiAl alloys in commercial aircraft engines. MRS Proc. 1516, 49–58 (2013). https://doi.org/10.1557/opl.2013.44

B. Jeong, J. Kim, T. Lee, S.W. Kim, S. Ryu, Systematic investigation of the deformation mechanisms of a γ-TiAl single crystal. Sci. Rep. 8, 15200 (2018). https://doi.org/10.1038/s41598-018-33377-z

Y.W. Kim, Intermetallic alloys based on gamma titanium aluminide. JOM 41, 24–30 (1989). https://doi.org/10.1007/BF03220267

P. Villar, L.D. Calvert (eds), Pearson’s Handbook of Crystallographic Data for Intermetallic Phases, Vol. 2, (1985), (American Society of Metals, Metals Park)

W.J. Zhang, B.V. Reddy, S.C. Deevi, Physical properties of TiAl-base alloys. Scr. Mater. 45, 645–651 (2001). https://doi.org/10.1016/S1359-6462(01)01075-2

B. Liu, Y. Liu, Powder metallurgy titanium aluminides alloys, Ch. 27 in Titanium Poder Metallurgy: Science, Technology, and Applications, Butterworth-Heinemann, ed. M. Qian and F. H. Froes, pp. 515–531 (2015). doi: https://doi.org/10.1016/B978-0-12-800054-0.00027-7

O. Genc, R. Unal, Development of gamma titanium aluminides (γ-TiAl) alloys: a review. J. Alloys Compd. 929, 167262 (2022). https://doi.org/10.1016/j.jallcom.2022.167262

Y. Liu, B. Tang, X.Y. Huang, L. Zhu, D. Liu, R. Yang, J.S. Li, Microstructural stability and creep properties of middle Nb γ-TiAl alloy with a modulated microstructure. Intermetallics 151(12), 107733 (2022). https://doi.org/10.1016/j.intermet.2022.107733

C.L. Fu, M.H. Yoo, Elastic constants, fault energies, and dislocation reactions in TiAl: a first-principles total-energy investigation. Philos. Mag. Lett. 62(3), 159–165 (1990). https://doi.org/10.1080/09500839008215053

Y. He, R.B. Schwarz, A. Migliori, S.H. Whang, Elastic constants of single crystal γ-TiAl. J. Mater. Res. 10(5), 1187–1195 (1995). https://doi.org/10.1557/JMR.1995.1187

Y. He, R.B. Schwarz, T. Darling, M. Hundley, S.H. Whang, Z.M. Wang, Elastic constants and thermal expansion of single crystal γ-TiAl from 300 to 750 K. Mater. Sci. Eng. A 239–240, 157–163 (1997). https://doi.org/10.1016/S0921-5093(97)00575-3

K. Tanaka, T. Ichitsubo, H. Inui, M. Yamaguchi, M. Koiwa, Single-crystal elastic constants of gamma-TiAl. Philos. Mag. Lett. 73(2), 71–78 (1996). https://doi.org/10.1080/095008396181019

J. Turley, G. Sines, The anisotropy of Young’s modulus, shear modulus and Poisson’s ratio in cubic materials. J. Phys. D 4(2), 264–271 (1971). https://doi.org/10.1088/0022-3727/4/2/312

D.J. Gunton, G.A. Saunders, The Young’s modulus and Poisson’s ratio of arsenic, antimony and bismuth. J. Mater. Sci. 7(9), 1061–1068 (1972). https://doi.org/10.1007/BF00550070

Y. Li, The anisotropic behavior of Poisson’s ratio, Young’s modulus, and shear modulus in hexagonal materials. Phys. Stat. Sol. A 38, 171–175 (1976). https://doi.org/10.1002/pssa.2210380119

R.J. Bisplinghoff, J.W. Mar, T.H.H. Pian, Statics of Deformable Solids (Addison-Wesley, Reading, MA, 1965)

B.A. Auld, Acoustics Fields and Waves in Solids, vol. 1 (Wiley, New York, 1973)

J.F. Nye, Physical Properties of Crystals (Oxford University Press, Oxford, 1985)

M.J.P. Musgrave, Crystal Acoustics. Ch. 3, Holden-Day, San Francisco, (1970)

J. Cao, F. Li, Critical Poisson’s ratio between toughness and brittleness. Phil Mag Lett 96(11), 425–431 (2016). https://doi.org/10.1080/09500839.2016.1243264

A.H. Love, A Treatise on the Mathematical Theory of Elasticity (Dover, New York, 1944)

T.H. Courtney, Mechanical Behavior of Materials (McGraw-Hill Inc, New York, 1990)

G.N. Greaves, A.L. Greer, R.S. Lakes, T. Rouxel, Poisson’s ratio and modern materials. Nat. Mater. 10, 823–837 (2011). https://doi.org/10.1038/nmat3134

R.H. Baughman, J.M. Shacklette, A.A. Zakhidov, S. Stafström, Negative Poisson’s ratios as a common feature of cubic metals. Nature 392, 362–365 (1998). https://doi.org/10.1038/32842

F. Milstein, K. Huang, Existence of a negative Poisson ratio in fcc crystals. Phys. Rev. B 19, 2030–2033 (1979). https://doi.org/10.1103/PhysRevB.19.2030

A. Yeganeh-Haeri, D.J. Weidner, J.B. Parise, Elasticity of α-cristobalite—a silicon dioxide with negative Poisson’s ratio. Science 257, 650–652 (1992). https://doi.org/10.1126/science.257.5070.650

M. Rovati, On the negative Poisson’s ratio of an orthorhombic alloy. Scr. Mater. 48(3), 235–240 (2003). https://doi.org/10.1016/S1359-6462(02)00386-X

R.S. Lakes, Foam structures with a negative Poisson’s ratio. Science 235, 1038–1040 (1987). https://doi.org/10.1126/science.235.4792.1038

R.S. Lakes, Advances in negative Poisson’s ratio materials. Adv. Mater. 5(4), 293–296 (1993). https://doi.org/10.1002/adma.19930050416

L. Yang, O. Harrysson, H. West, D. Cormier, Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing. Int. J. Solids Structures 69–70, 475–490 (2015). https://doi.org/10.1016/j.ijsolstr.2015.05.005

K.E. Evans, M.A. Nkansah, I.J. Hutchinson, S.C. Rogers, Molecular network design. Nature 353, 124 (1991). https://doi.org/10.1038/353124a0

B.D. Caddock, K.E. Evans, Microporous materials with negative Poisson’s ratios. I. Microstructure and mechanical properties. J. Phys. D 22(12), 1877–1882 (1989). https://doi.org/10.1088/0022-3727/22/12/012

G.W. Milton, Composite materials with Poisson’s ratios close to −1. J. Mech. Phys. Solids 40, 1105–1137 (1992). https://doi.org/10.1016/0022-5096(92)90063-8

X.K. Ma, J. Liu, Y.C. Fan, J.F. Hu, M.W. Zhao, Giant negative Poisson’s ratio in two-dimensional V-shaped materials. Nanoscale Adv. 3, 4554–4560 (2021). https://doi.org/10.1039/d1na00212k

N. Keskar, J. Chelikowsky, Negative Poisson ratios in crystalline SiO2 from first-principles calculations. Nature 358, 222–224 (1992). https://doi.org/10.1038/358222a0

T.C.T. Ting, T.Y. Chen, Poisson’s ratio for anisotropic elastic materials can have no bounds. Quart. J. Mech. Appl. Math. 58(1), 73–82 (2005). https://doi.org/10.1093/qjmamj/hbh021

Acknowledgments

I would like to thank Drs. R. B. Schwarz, A. Migliori, S. H. Whang for their help and useful discussions during the elastic constant measurements of γ-TiAl.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that he has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

He, Y. Orientational dependence of Poisson’s ratio in tetragonal γ-TiAl single crystal. MRS Communications 13, 431–437 (2023). https://doi.org/10.1557/s43579-023-00376-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00376-9