Abstract

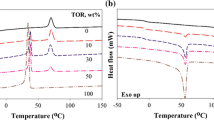

In this study, heat-responsive shape memory thermoplastic polymer blends were developed using a solution blending technique. The blends consisted of maleic anhydride grafted SEBS (SEBS-g-MA) as the elastomer phase and poly(caprolactone) (PCL) as the switch phase. The investigation focused on understanding the effects of blend composition on morphological and mechanical properties. Blends containing 40 and 50 wt % of PCL (SEBS60 and SEBS50, respectively) exhibited a co-continuous morphology. Increasing the PCL content led to higher Young’s modulus and storage modulus at room temperature, while decreasing the creep strain. Shape-memory tests demonstrated promising results, with shape fixing ratios (Rf) reaching up to 98.54% and shape recovery ratios (Rr) up to 84.01%. Notably, the SEBS60 blend displayed the best shape-memory performance, achieving an Rf value of 97.15% and an Rr value of 76.29%. Cyclic shape-memory tests for the same blend maintained Rf values above 96% and Rr values above 82%.

Graphical abstract

Similar content being viewed by others

Data availability

The data are not publicly available.

Code availability

Not applicable.

References

H. Meng, G. Li, A review of stimuli-responsive shape memory polymer composites. Polymer 54(9), 2199 (2013). https://doi.org/10.1016/j.polymer.2013.02.023

W. Wang, Y. Liu, J. Leng, Recent developments in shape memory polymer nanocomposites: actuation methods and mechanisms. Coord. Chem. Rev. 320, 38 (2016). https://doi.org/10.1016/j.ccr.2016.03.007

A. Ben Abdallah, F. Gamaoun, A. Kallel, A. Tcharkhtchi, Molecular weight influence on shape memory effect of shape memory polymer blend (poly (caprolactone)/styrene-butadiene-styrene). J. Appl. Polym. Sci. 138(5), 49761 (2021). https://doi.org/10.1002/app.49761

J. Li, T. Liu, S. Xia, Y. Pan, Z. Zheng, X. Ding, Y. Peng, A versatile approach to achieve quintuple-shape memory effect by semi-interpenetrating polymer networks containing broadened glass transition and crystalline segments. J. Mater. Chem. 21(33), 12213 (2011). https://doi.org/10.1039/C1JM12496J

E. Tekay, Thermo-responsive shape memory behavior of poly (styrene-b-isoprene-b-styrene)/ethylene-1-octene copolymer thermoplastic elastomer blends. Polym. Adv. Technol. 32(1), 428 (2021). https://doi.org/10.1002/pat.5139

S. Song, J. Feng, P. Wu, A new strategy to prepare polymer-based shape memory elastomers. Macromol. Rapid Commun. 32(19), 1569 (2011). https://doi.org/10.1002/marc.201100298

E. Tekay, Isıl-duyarlı şekil hafızalı kopoliester termoplastik elastomer (COPE) ve poli (etilen-ko-vinil asetat)(EVA) polimer harmanlarının hazırlanması. Fac. Eng. Archit. Gazi Univ. 36(1), 241 (2020). https://doi.org/10.17341/gazimmfd.722364

S.A. Abdullah, A. Jumahat, N.R. Abdullah, L. Frormann, Determination of shape fixity and shape recovery rate of carbon nanotube-filled shape memory polymer nanocomposites. Procedia Eng. 41, 1641 (2012). https://doi.org/10.1016/j.proeng.2012.07.362

X. Jing, H.-Y. Mi, H.-X. Huang, L.-S. Turng, Shape memory thermoplastic polyurethane (TPU)/poly (ε-caprolactone)(PCL) blends as self-knotting sutures. J. Mech. Behav. Biomed. Mater. 64, 94 (2016). https://doi.org/10.1016/j.jmbbm.2016.07.023

C. Schmidt, K. Neuking, G. Eggeler, Functional fatigue of shape memory polymers. Adv. Eng. Mater. 10(10), 922 (2008). https://doi.org/10.1002/adem.200800213

Y. Guo, J. Ma, Z. Lv, N. Zhao, L. Wang, Q. Li, The effect of plasticizer on the shape memory properties of poly (lactide acid)/poly (ethylene glycol) blends. J. Mater. Res. 33(23), 4101 (2018). https://doi.org/10.1557/jmr.2018.359

K.P. Mineart, S.S. Tallury, T. Li, B. Lee, R.J. Spontak, Phase-change thermoplastic elastomer blends for tunable shape memory by physical design. Ind. Eng. Chem. Res. 55(49), 12590 (2016). https://doi.org/10.1021/acs.iecr.6b04039

G. Holden, E. Bishop, N.R. Legge, Thermoplastic elastomers. J. Polym Sci Part C 26, 37 (1969)

A. Wilkinson, M. Clemens, V. Harding, The effects of SEBS-g-maleic anhydride reaction on the morphology and properties of polypropylene/PA6/SEBS ternary blends. Polymer 45(15), 5239 (2004). https://doi.org/10.1016/j.polymer.2004.05.033

Z. Kordjazi, N.G. Ebrahimi, Rheological behavior of noncompatibilized and compatibilized PP/PET blends with SEBS-g-MA. J. Appl. Polym. Sci. 116(1), 441 (2010). https://doi.org/10.1002/app.31471

W. Liu, R. Zhang, M. Huang, X. Dong, W. Xu, N. Ray, J. Zhu, Design and structural study of a triple-shape memory PCL/PVC blend. Polymer 104, 115 (2016). https://doi.org/10.1016/j.polymer.2016.09.079

E.G. Choubar, M.H. Nasirtabrizi, F. Salimi, N. Sohrabi-gilani, A. Sadeghianamryan, Fabrication and in vitro characterization of novel co-electrospun polycaprolactone/collagen/polyvinylpyrrolidone nanofibrous scaffolds for bone tissue engineering applications. J. Mater. Res. 37(23), 4140 (2022). https://doi.org/10.1557/s43578-022-00778-w

A. Sali, S. Duzyer Gebizli, G. Goktalay, Silymarin-loaded electrospun polycaprolactone nanofibers as wound dressing. J. Mater. Res. 38(8), 2251 (2023). https://doi.org/10.1557/s43578-023-00959-1

W. Kuang, P.T. Mather, A latent crosslinkable PCL-based polyurethane: synthesis, shape memory, and enzymatic degradation. J. Mater. Res. 33(17), 2463 (2018). https://doi.org/10.1557/jmr.2018.220

H. Zhang, H. Wang, W. Zhong, Q. Du, A novel type of shape memory polymer blend and the shape memory mechanism. Polymer 50(6), 1596 (2009). https://doi.org/10.1016/j.polymer.2009.01.011

E. Tekay, Preparation and characterization of electro-active shape memory PCL/SEBS-g-MA/MWCNT nanocomposites. Polymer 209, 122989 (2020). https://doi.org/10.1016/j.polymer.2020.122989

B. Peng, Y. Yang, T. Ju, K.A. Cavicchi, Fused filament fabrication 4D printing of a highly extensible, self-healing, shape memory elastomer based on thermoplastic polymer blends. ACS Appl. Mater. Interfaces 13(11), 12777 (2020). https://doi.org/10.1021/acsami.0c18618

E. Tekay, S. Şen, M.A. Korkmaz, N. Nugay, Preparation and characterization of thermo-responsive shape memory ester-based polymer blends. J. Mater. Sci. 58(19), 8241 (2023). https://doi.org/10.1007/s10853-023-08549-6

R. Nehra, S.N. Maiti, J. Jacob, Analytical interpretations of static and dynamic mechanical properties of thermoplastic elastomer toughened PLA blends. J. Appl. Polym. Sci. 135(1), 45644 (2018). https://doi.org/10.1002/app.45644

M. Vanneste, G. Groeninckx, Ternary blends of PCL, SAN15 and SMA14: miscibility, crystallization and melting behaviour, and semicrystalline morphology. Polymer 36(22), 4253 (1995). https://doi.org/10.1016/0032-3861(95)92221-Y

S. Moradi, J.K. Yeganeh, Highly toughened poly (lactic acid)(PLA) prepared through melt blending with ethylene-co-vinyl acetate (EVA) copolymer and simultaneous addition of hydrophilic silica nanoparticles and block copolymer compatibilizer. Polym. Test. 91, 106735 (2020). https://doi.org/10.1016/j.polymertesting.2020.106735

M. Kashif, Y.-W. Chang, Triple-shape memory effects of modified semicrystalline ethylene–propylene–diene rubber/poly (ε-caprolactone) blends. Eur. Polym. J. 70, 306 (2015). https://doi.org/10.1016/j.eurpolymj.2015.07.026

M. Sabzi, M. Babaahmadi, M. Rahnama, Thermally and electrically triggered triple-shape memory behavior of poly (vinyl acetate)/poly (lactic acid) due to graphene-induced phase separation. ACS Appl. Mater. Interfaces 9(28), 24061 (2017). https://doi.org/10.1021/acsami.7b02259

D. Ponnamma, K.K. Sadasivuni, M. Strankowski, P. Moldenaers, S. Thomas, Y. Grohens, Interrelated shape memory and Payne effect in polyurethane/graphene oxide nanocomposites. RSC Adv. 3(36), 16068 (2013). https://doi.org/10.1039/C3RA41395K

S.M. Lai, X.F. Wang, Shape memory properties of olefin block copolymer (OBC)/poly (ɛ-caprolactone)(PCL) blends. J. Appl. Polym. Sci. 134(44), 45475 (2017). https://doi.org/10.1002/app.45475

Y. Wei, R. Huang, P. Dong, X.-D. Qi, Q. Fu, Preparation of polylactide/poly (ether) urethane blends with excellent electro-actuated shape memory via incorporating carbon black and carbon nanotubes hybrids fillers. Chin. J. Polym. Sci. 36, 1175 (2018). https://doi.org/10.1007/s10118-018-2138-3

Acknowledgments

Supports given by The Scientific and Technological Research Council of Türkiye (TUBITAK) (Project No. 221M074) and Yalova University Scientific Research Projects Coordination Department are gratefully acknowledged.

Funding

This work was supported by The Scientific and Technological Research Council of Türkiye (TUBITAK) (Project No. 221M074) and Yalova University Scientific Research Projects Coordination Department.

Author information

Authors and Affiliations

Contributions

ET: conceptualization, supervision, methodology design, writing-reviewing-editing of the manuscript, material preparation, and characterizations of the materials. SŞ: writing-reviewing-editing of the manuscript, and characterizations of the materials.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 62969 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tekay, E., Şen, S. Investigation of shape memory and mechanical properties of styrenic thermoplastic elastomer/PCL blends: Effect of blend composition. Journal of Materials Research 38, 5065–5077 (2023). https://doi.org/10.1557/s43578-023-01225-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01225-0