Abstract

In 18Ni300 maraging steel (MS) prepared by laser metal deposition (LMD), Ni3Al intermetallic compound is precipitated due to intrinsic heat treatment (IHT). Precipitation strengthening of the samples by IHT without further heat treatment is a prospective way to boost the mechanical behaviors of MS. The properties of the samples are represented by field emission scanning electron microscopy (FSEM), hardness measurement, tribological test, and potentiodynamic polarization test. The results indicate that these specimens are constituted by massive martensite, slight retained austenite, and intermetallic compounds. The hardness of the sample increases by 202 HV with the addition of Al. When the 6 at% atom Al is added, the sample with relatively good wear and corrosion resistance was obtained. When the Al concentration is 12%, the microstructure evolves from the equiaxed dendrite structure to coarse-grained martensite, which brings about the reduction of the mechanical properties of MS + 12 at.% Al.

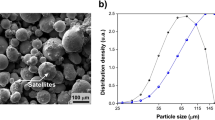

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

C. Zhang, C. Wang, S.L. Zhang, Y.L. Ding, Q.L. Ge, J. Su, Effect of aging temperature on the precipitation behavior and mechanical properties of Fe–Cr–Ni maraging stainless steel. J Mater. Sci. Eng. A 806, 140763 (2021). https://doi.org/10.1016/j.msea.2021.140763

Y.C. Bai, Y.Q. Yang, D. Wang, M.K. Zhang, Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting. J. Mater. Sci. Eng. A 703, 116–123 (2017). https://doi.org/10.1016/j.msea.2017.06.033

K. Kempen, E. Yasa, L. Thijs, J. Van Humbeeck, Microstructure and mechanical properties of selective laser melted 18Ni-300 steel. J. Phys. Procedia. 12, 255–263 (2011). https://doi.org/10.1016/j.phpro.2011.03.033

F. Tariq, M. Shifa, R.A. Baloch, Effect of overaging conditions on microstructure and mechanical properties of maraging steel. J. Met. Sci. Heat Treat. 62, 188–194 (2020). https://doi.org/10.1007/s11041-020-00535-y

Y.Z. Lek, C. Wang, X. Shen et al., Additive manufacturing of corrosion-resistant maraging steel M789 by directed energy deposition. Mater. Sci. Eng. A 857, 144032 (2022)

D.P.M. Fonseca, A.L.M. Feitosa, L.G. Carvalho et al., A short review on ultra-high-strength maraging steels and future perspectives. Mater. Res. (2021). https://doi.org/10.1590/1980-5373-mr-2020-0470

Y. Bai, Y. Yang, Z. Xiao et al., Selective laser melting of maraging steel: mechanical properties development and its application in mold. Rapid Prototyp. J. 24(3), 623–629 (2018)

C.L. Tan, K.S. Zhou, W.Y. Ma, P.P. Zhang, M. Liu, T.C. Kuang, Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. J. Mater. Des. 134, 23–34 (2017). https://doi.org/10.1016/j.matdes.2017.08.026

N. Takata, R. Nishida, A. Suzuki, M. Kobashi, M. Kato, Crystallographic features of microstructure in maraging steel fabricated by selective laser melting. J. Met. 8, 440 (2018). https://doi.org/10.3390/met8060440

T.H. Simm, L. Sun, D.R. Galvin, P. Hill, M. Rawson, S. Birosca, E.P. Gilbert, H. Bhadeshia, K. Perkins, The effect of a two-stage heat-treatment on the microstructural and mechanical properties of a maraging steel. J. Mater. 10, 1346 (2017). https://doi.org/10.3390/ma10121346

B. Mooney, K.I. Kourousis, R. Raghavendra, Plastic anisotropy of additively manufactured maraging steel: influence of the build orientation and heat treatments. J. Addit. Manuf. 25, 19–31 (2019). https://doi.org/10.1016/j.addma.2018.10.032

D. Kim, T. Kim, K. Ha, J.J. Oak, J.B. Jeon, Y. Park, W. Lee, Effect of heat treatment condition on microstructural and mechanical anisotropies of selective laser melted maraging 18Ni-300 steel. J. Met. 10, 410 (2020). https://doi.org/10.3390/met10030410

E.A. Jägle, P.P. Choi, J. Van Humbeeck, D. Rabbe, Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J. Mater. Res. 29, 2072–2079 (2014). https://doi.org/10.1557/jmr.2014.204

E.A. Jägle, Z.D. Sheng, L. Wu, L. Lu, J. Risse, A. Weisheit, D. Raabe, Precipitation reactions in age-hardenable alloys during laser additive manufacturing. J. Jom. 68, 943–949 (2016). https://doi.org/10.1007/s11837-015-1764-2

J. Suryawanshi, K.G. Prashanth, U. Ramamurty, Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting. J. Alloys Compd. 725, 355–364 (2017). https://doi.org/10.1016/j.jallcom.2017.07.177

R. Casati, J.N. Lemke, A. Tuissi, M. Vedani, Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. J. Met. 6, 218 (2016). https://doi.org/10.3390/met6090218

S. Yin, C.Y. Chen, X.C. Yan, X.H. Feng, R. Jenkins, P. O’Reilly, M. Liu, H. Li, R. Lupoi, The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel. J. Addit. Manuf. 22, 592–600 (2018). https://doi.org/10.1016/j.addma.2018.06.005

S. Anoop, A. Venugopal, S. Dineshraj, S.V.S.N. Murty, B. Pant, Stress corrosion cracking behavior of selective laser-melted M300 maraging steel in 3.5 wt.% NaCl solution. J. Mater. Eng. Perform. 30, 6568–6578 (2021). https://doi.org/10.1007/s11665-021-05913-y

A. Shahriari, L. Khaksar, A. Nasiri, A. Hadadzadeh, B.S. Amirkhiz, M. Mohammadi, Microstructure and corrosion behavior of a novel additively manufactured maraging stainless steel. J Electrochim. Acta 339, 135925 (2020). https://doi.org/10.1016/j.electacta.2020.135925

K.M. Wang, D. Du, G. Liu, Z. Pu, B.H. Chang, J. Ju, High-temperature oxidation behaviour of high chromium superalloys additively manufactured by conventional or extreme high-speed laser metal deposition. J. Corros. Sci. 176, 108922 (2020). https://doi.org/10.1016/j.corsci.2020.108922

J.D. Wang, Y.Z. Zeng, X.P. Qi, Y. Xue, D. Xu, L.Q. Li, Y.X. Tong, F.C. Jiang, Graded microstructure and properties of TiCp/Ti6Al4V composites manufactured by laser melting deposition. J. Ceram. Int. 48, 6985–6997 (2022). https://doi.org/10.1016/j.ceramint.2021.11.256

D.D. Gu, Y.C. Hagedorn, W. Meiners, K. Wissenbach, R. Poprawe, Selective laser melting of in-situ TiC/Ti5Si3 composites with novel reinforcement architecture and elevated performance. J. Surf. Coat. Technol. 205, 3285–3292 (2011). https://doi.org/10.1016/j.surfcoat.2010.11.051

T. Kühnle, K. Partes, In-situ formation of titanium boride and titanium carbide by selective laser melting. J. Phys. Procedia. 39, 432–438 (2012). https://doi.org/10.1016/j.phpro.2012.10.058

Y.M. Zou, C.L. Tan, Z.G. Qiu, W.Y. Ma, M. Kuang, D.C. Zeng, Additively manufactured SiC-reinforced stainless steel with excellent strength and wear resistance. J. Addit. Manuf. 41, 101971 (2021). https://doi.org/10.1016/j.addma.2021.101971

R.F. Schaller, J.M. Taylor, J. Rodelas, E.J. Schindelholz, Corrosion properties of powder bed fusion additively manufactured 17–4 PH stainless steel. J. Corros. 73, 796–807 (2017). https://doi.org/10.5006/2365

P. Kürnsteiner, M.B. Wilms, A. Weisheit, P. Barriobero-Vila, E.A. Jägle, D. Raabe, Massive nanoprecipitation in an Fe-19Ni-xAl maraging steel triggered by the intrinsic heat treatment during laser metal deposition. J. Acta Mater. 129, 52–60 (2017). https://doi.org/10.1016/j.actamat.2017.02.069

A. Langebeck, A. Bohlen, R. Rentsch, F. Vollertsen, Mechanical properties of high strength aluminum alloy EN AW-7075 additively manufactured by directed energy deposition. J. Met. 10, 579 (2020). https://doi.org/10.3390/met10050579

H.S. Prasad, F. Brueckner, J. Volpp, A.F.H. Kaplan, Laser metal deposition of copper on diverse metals using green laser sources. Int. J. Adv. Manuf. Technol. 107, 1559–1568 (2020). https://doi.org/10.1007/s00170-020-05117-z

M. Boutaous, X. Liu, D.A. Siginer, S.H. Xin, Balling phenomenon in metallic laser based 3D printing process. Int. J. Therm. Sci. 167, 107011 (2021). https://doi.org/10.1016/j.ijthermalsci.2021.107011

A. Chabot, N. Laroche, E. Carcreff, M. Rauch, J.Y. Hascoet, Towards defect monitoring for metallic additive manufacturing components using phased array ultrasonic testing. J. Intell. Manuf. 31, 1191–1201 (2020). https://doi.org/10.1007/s10845-019-01505-9

C. Félix-Martínez, J. Ibarra-Medina, D.A. Fernández-Benavides, L.A. Caceres-Diaz, J.M. Alvarado-Orozco, Effect of the parametric optimization and heat-treatment on the 18Ni-300 maraging steel microstructural properties manufactured by directed energy deposition. Int. J. Adv. Manuf. Technol. 115, 3999–4020 (2021). https://doi.org/10.1007/s00170-021-07320-y

S.Q. Wang, T.L. Zhao, Z.Y. Liu, C.W. Du, X.G. Li, Exploration of the processing scheme of a novel Ni(Fe, Al)-maraging steel. J. Mater. Res. Technol. 10, 225–239 (2020). https://doi.org/10.1016/j.jmrt.2020.12.020

C. Tan, K. Zhou, M. Kuang et al., Microstructural characterization and properties of selective laser melted maraging steel with different build directions. Sci. Technol. Adv. Mater. 19(1), 746–758 (2018)

C.L. Tan, K.S. Zhou, M. Kuang, W.Y. Ma, T.C. Kuang, Microstructural characterization and properties of selective laser melted maraging steel with different build directions. J. Sci. Technol. Adv. Mater. 19, 746–758 (2018). https://doi.org/10.1080/14686996.2018.1527645

Y.J. Wang, J.J. Sun, T. Jiang, Y. Sun, S.W. Guo, Y.N. Liu, A low-alloy high-carbon martensite steel with 2.6GPa tensile strength and good ductility. J. Acta Mater. 158, 247–256 (2018). https://doi.org/10.1016/j.actamat.2018.07.060

A. Hadadzadeh, A. Shahriari, B.S. Amirkhiz, J. Li, M. Mohammadi, Additive manufacturing of an Fe–Cr–Ni–Al maraging stainless steel: Microstructure evolution, heat treatment, and strengthening mechanisms. J. Mater. Sci. Eng. A 787, 139470 (2020). https://doi.org/10.1016/j.msea.2020.139470

S. Karagoz, H.F. Fischmeister, Cutting performance and microstructure of high speed steels: contributions of matrix strengthening and undissolved carbides. J. Metall. Mater. Trans. A 29, 205–216 (1998). https://doi.org/10.1007/s11661-998-0173-3

M. Vardavoulias, The role of hard second phases in the mild oxidational wear mechanism of high-speed steel-based materials. J. Wear 173, 105–114 (1994). https://doi.org/10.1016/0043-1648(94)90262-3

H.N. Xiao, C.J. Chen, M. Zhang, Microstructure and mechanical properties of H13 steel/high-speed steel composites prepared by laser metal deposition. J. Mater. Eng. Perform. 29, 66–77 (2019). https://doi.org/10.1007/s11665-019-04476-3

Y.G. Zhao, W. Liu, T.Y. Zhang, Y.B. Wang, Y.M. Fan, B.J. Dong, Assessment of the correlation between M23C6 precipitates and pitting corrosion resistance of 0Cr13 martensitic stainless steel. Corros. Sci. 189, 109580 (2021). https://doi.org/10.1016/j.corsci.2021.109580

Y. Li, Z.Y. Liu, E.D. Fan, Y.H. Huang, Y. Fan, B.J. Zhao, Effect of cathodic potential on stress corrosion cracking behavior of different heat-affected zone microstructures of E690 steel in artificial seawater. J. Mater. Sci. Technol. 64, 141–152 (2021). https://doi.org/10.1016/j.jmst.2019.08.029

A.E. Avelino, W.S. Araújo, D.F. Dias, L.P.M. dos Santos, A.N. Correia, P. de Lima-Neto, Corrosion investigation of the 18Ni 300 grade maraging steel in aqueous chloride medium containing H2S and CO2. J. Electrochim. Acta 286, 339–349 (2018). https://doi.org/10.1016/j.electacta.2018.08.042

T. Narayanan, J. Kim, H.E. Jeong, H.W. Park, Enhancement of the surface properties of selective laser melted maraging steel by large pulsed electron-beam irradiation. J. Addit. Manuf. 33, 101125 (2020). https://doi.org/10.1016/j.addma.2020.101125

Acknowledgments

We would like to appreciate the State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology [Grant No. SKLAB02014006], the Suzhou Science and Technology Bureau [Grant No. SYG201231, No. SYG201642], the Open Fund for Jiangsu Key Laboratory of Advanced Manufacturing Technology [Grant No. HGAMTL-1701], and the Jiangsu Province 333 Talent Project [Grant No. BRA2017098].

Funding

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Author information

Authors and Affiliations

Contributions

LJ: investigation, writing–original draft, formal analysis, methodology, validation. CC: conceptualisation, formal analysis, funding acquisition, resources, supervision. MZ: conceptualisation, formal analysis, supervision, methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this thesis.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, C., Chen, C., Jiang, L. et al. Design of maraging steel with aluminum by laser metal deposition. Journal of Materials Research 38, 3022–3033 (2023). https://doi.org/10.1557/s43578-023-01022-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01022-9