Abstract

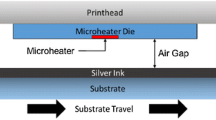

Selective spatial heating is relevant for a number of applications and is enabled by the deposition of heterogeneous materials. Here, we report the automated spray deposition and Joule heating of carbon ink in unique spatial designs to generate on-demand thermal patterns. We demonstrate an automated process using an airbrush-equipped machine to deposit carbon ink onto an electric circuit in a pattern specified to match an arbitrary input. The deposited ink undergoes Joule heating when applied with direct current power, with heating rate inversely proportional to surface resistance. We show that higher areal densities of deposited ink correlate with higher temperatures, which allows for spatial heat patterns, easily achieving temperatures over 100 °C. We find that the resolution (typically on the order of mm) of generated thermal patterns is determined by the applicator geometry and lateral thermal diffusion. The scalability of the automated ink deposition process is demonstrated using a modular applicator design for thermal displays. The resulting thermal patterns also hold promise for use in de-icing systems and site-specific thermoset curing.

Graphical Abstract

Patterned deposition of carbon ink onto a circuit for Joule heating allows for the desired thermal pattern to be generated.

Similar content being viewed by others

Data availability

Data are available upon reasonable request.

References

D. Janas, K.K. Koziol, Rapid electrothermal response of high-temperature carbon nanotube film heaters. Carbon 59, 457–463 (2013)

X. Chen, H. Gao, G. Hai, D. Jia, L. Xing, S. Chen, P. Cheng, M. Han, W. Dong, G. Wang, Carbon nanotube bundles assembled flexible hierarchical framework based phase change material composites for thermal energy harvesting and thermotherapy. Energy Storage Mater. 26, 129–137 (2020)

V.K. Hicks, M. Anas, E.B. Porter, M.J. Green, High-throughput screening of printed carbon nanotube circuits using radio frequency heating. Carbon 152, 444–450 (2019)

J.C. Gerringer, A.G. Moran, T. Habib, M.J. Pospisil, J.H. Oh, B.R. Teipel, M.J. Green, Radio frequency heating of laser-induced graphene on polymer surfaces for rapid welding. ACS Appl. Nano Mater. 2, 7032–7042 (2019)

C.B. Sweeney, M.L. Burnette, M.J. Pospisil, S.A. Shah, M. Anas, B.R. Teipel, B.S. Zahner, D. Staack, M.J. Green, Dielectric barrier discharge applicator for heating carbon nanotube-loaded interfaces and enhancing 3D-printed bond strength. Nano Lett. 20, 2310–2315 (2020)

D. Janas, K.K. Koziol, A review of production methods of carbon nanotube and graphene thin films for electrothermal applications. Nanoscale 6, 3037–3045 (2014)

B. Philip, E. Jewell, P. Greenwood, C. Weirman, Material and process optimization screen printing carbon graphite pastes for mass production of heating elements. J. Manuf. Process. 22, 185–191 (2016)

Y. Hao, M. Tian, H. Zhao, L. Qu, S. Zhu, X. Zhang, S. Chen, K. Wang, J. Ran, High efficiency electrothermal graphene/tourmaline composite fabric joule heater with durable abrasion resistance via a spray coating route. Ind. Eng. Chem. Res. 57, 13437–13448 (2018)

C.B. Sweeney, B.A. Lackey, M.J. Pospisil, T.C. Achee, V.K. Hicks, A.G. Moran, B.R. Teipel, M.A. Saed, M.J. Green, Welding of 3D-printed carbon nanotube–polymer composites by locally induced microwave heating. Sci. Adv. 3, e1700262 (2017)

C.B. Sweeney, A.G. Moran, J.T. Gruener, A.M. Strasser, M.J. Pospisil, M.A. Saed, M.J. Green, Radio Frequency heating of carbon nanotube composite materials. ACS Appl. Mater. Interfaces. 10, 27252–27259 (2018)

T. Habib, N. Patil, X. Zhao, E. Prehn, M. Anas, J.L. Lutkenhaus, M. Radovic, M.J. Green, Heating of Ti3C2Tx MXene/polymer composites in response to radio frequency fields. Sci. Rep. 9, 16489 (2019)

M. Anas, Y. Zhao, M.A. Saed, K.J. Ziegler, M.J. Green, Radio frequency heating of metallic and semiconducting single-walled carbon nanotubes. Nanoscale 11, 9617–9625 (2019)

M. Haile, C.B. Sweeney, B.A. Lackey, O. Sarwar, R. Henderson, M.A. Saed, M.J. Green, J.C. Grunlan, Ultrafast and highly localized microwave heating in carbon nanotube multilayer thin films. Adv. Mater. Interfaces 4, 1700371 (2017)

S.J. Corr, M. Raoof, B.T. Cisneros, A.W. Orbaek, M.A. Cheney, J.J. Law, N.C. Lara, A.R. Barron, L.J. Wilson, S.A. Curley, Radiofrequency electric-field heating behaviors of highly enriched semiconducting and metallic single-walled carbon nanotubes. Nano Res. 8, 2859–2870 (2015)

J. Chen, Y. Wang, F. Liu, S. Luo, Laser-induced graphene paper heaters with multimodally patternable electrothermal performance for low-energy manufacturing of composites. ACS Appl. Mater. Interfaces. 12, 23284–23297 (2020)

P.-H. Wang, S.-P. Chen, C.-H. Su, Y.-C. Liao, Direct printed silver nanowire thin film patterns for flexible transparent heaters with temperature gradients. RSC Adv. 5, 98412–98418 (2015)

C.-P. Wang, M.-H. Hsiao, G.-H. Lee, T.-L. Chang, Y.-W. Lee, The investigation of electrothermal response and reliability of flexible graphene micro-heaters. Microelectron. Eng. 228, 111334 (2020)

K. Parida, H. Bark, P.S. Lee, Emerging thermal technology enabled augmented reality. Adv. Func. Mater. 31, 2007952 (2021)

L. Pan, Z. Liu, O. kiziltaş, L. Zhong, X. Pang, F. Wang, Y. Zhu, W. Ma, Y. Lv, Carbon fiber/poly ether ether ketone composites modified with graphene for electro-thermal deicing applications. Compos. Sci. Technol. 192, 108117 (2020)

P. Liu, L. Liu, K. Jiang, S. Fan, Carbon-Nanotube-Film Microheater on a Polyethylene Terephthalate Substrate and Its Application in Thermochromic Displays. Small 7, 732–736 (2011)

P. Liu, L. Liu, Y. Wei, K. Liu, Z. Chen, K. Jiang, Q. Li, S. Fan, Fast High-Temperature Response of Carbon Nanotube Film and Its Application as an Incandescent Display. Adv. Mater. 21, 3563–3566 (2009)

R. Hu, S. Huang, M. Wang, X. Luo, J. Shiomi, C.-W. Qiu, Encrypted Thermal printing with regionalization transformation. Adv. Mater. 31, 1807849 (2019)

J. Lee, H. Sul, W. Lee, K.R. Pyun, I. Ha, D. Kim, H. Park, H. Eom, Y. Yoon, J. Jung, D. Lee, S.H. Ko, Stretchable skin-like cooling/heating device for reconstruction of artificial thermal sensation in virtual reality. Adv. Func. Mater. 30, 1909171 (2020)

N. Athanasopoulos, V. Kostopoulos, Damage detection via Joule effect for multidirectional carbon fiber reinforced composites. Appl. Phys. Lett. 101, 114109 (2012)

A. Todoroki, M. Ueda, Y. Hirano, Strain and damage monitoring of CFRP laminates by means of electrical resistance measurement. J. Solid Mech. Mater. Eng. 1, 947–974 (2007)

A. Sarmah, S.K. Desai, G.B. Tezel, A. Vashisth, M.M. Mustafa, K. Arole, A.G. Crowley, M.J. Green, Rapid manufacturing via selective radio-frequency heating and curing of thermosetting resins. Adv. Eng. Mater. (2022). https://doi.org/10.1002/adem.202101351

S. Li, Y. Li, J. Zhou, Y. Wen, Improvement of Heating Uniformity by Limiting the Absorption of Hot Areas in Microwave Processing of CFRP Composites. Materials 14, 7769 (2021)

A.-T. Chien, S. Cho, Y. Joshi, S. Kumar, Electrical conductivity and Joule heating of polyacrylonitrile/carbon nanotube composite fibers. Polymer 55, 6896–6905 (2014)

M.O. Faruk, A. Ahmed, M.A. Jalil, M.T. Islam, A.M. Shamim, B. Adak, M.M. Hossain, S. Mukhopadhyay, Functional textiles and composite based wearable thermal devices for Joule heating: progress and perspectives. Appl. Mater. Today 23, 101025 (2021)

B. Mas, J.P. Fernández-Blázquez, J. Duval, H. Bunyan, J.J. Vilatela, Thermoset curing through Joule heating of nanocarbons for composite manufacture, repair and soldering. Carbon 63, 523–529 (2013)

Y. Wang, Z. Liu, H. Gu, C. Cui, J. Hao, Improved mechanical properties of 3D-printed SiC/PLA composite parts by microwave heating. J. Mater. Res. 34, 3412–3419 (2019)

M. Anas, M.M. Mustafa, D.G. Carey, A. Sarmah, J.J. LeMonte, M.J. Green, Joule heating of carbon pixels for on-demand thermal patterning. Carbon 174, 518–523 (2021)

J. Zhou, Y. Li, S. Liu, Y. Zhang, P. Wang, S. Sui, Zone-regulated microwave heating of CFRP laminates via ultrathin and flexible resonance structures with different working frequencies. Compos. Commun. 29, 101016 (2022)

S. Liu, Y. Li, Q. Liu, K. Xu, J. Zhou, Y. Shen, Z. Yang, X. Hao, Thermal manipulation in multi-layered anisotropic materials via computed thermal patterning. Adv. Func. Mater. 32, 2109674 (2022)

J. Perelaer, U.S. Schubert, Novel approaches for low temperature sintering of inkjet-printed inorganic nanoparticles for roll-to-roll (R2R) applications. J. Mater. Res. 28, 564–573 (2013)

A. Vashisth, S.T. Upama, M. Anas, J.-H. Oh, N. Patil, M.J. Green, Radio frequency heating and material processing using carbon susceptors. Nanoscale Adv. 3, 5255–5264 (2021)

Acknowledgments

We acknowledge helpful discussions with Dr. M. Anas of TAMU, Ms. Ava Crowley of the University of Colorado, Mr. Micah Lies and Dr. Lee Moores of ERDC, and Dr. Josh LeMonte of BYU. This work was funded by the US Army Engineer Research and Development Center in Vicksburg, MS.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hauschel, A.B., Carey, D.G., Fishbeck, B.J. et al. Automated deposition and Joule heating of carbon ink for the generation of on-demand unique thermal patterns. Journal of Materials Research 38, 2137–2144 (2023). https://doi.org/10.1557/s43578-023-00964-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-00964-4