Abstract

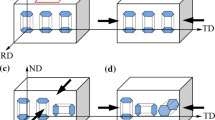

\(\{\textbf{1}\,\textbf{0}\,\bar{\textbf{1}}\,\textbf{2}\}\) twinning in magnesium AZ31 alloy activates profusely under c-axis tension (tension twinning) or d-axis compression (extension twinning). In a three-point bending condition, a strongly basal textured Mg AZ31 alloy offers a d-axis compression along \(\langle \textbf{1}\,\textbf{0}\,\bar{\textbf{1}}\,\textbf{0} \rangle\) direction ensuing in a pattern of localized twinning events. A micromechanics-based analytical solution is used to calculate strain energy and energies involved for various patterns of localized twins. The results reveal a minimum energy path of twinning evolution, predicting first twin propagation to the neutral axis, nucleation of a second twin at a certain distance from the first one, with the microstructure finally evolving to a favorable twinning pattern to accommodate the total bending strain. The results show the effect of multivariant twinning on the overall accommodation of bending strain. The twinning behaviors observed from this analysis compare well with the experimental results.

Graphical abstract

Similar content being viewed by others

Data availablity

Data will be made available on reasonable request.

References

T. Al-Samman, G. Gottstein, Room temperature formability of a magnesium AZ31 alloy: examining the role of texture on the deformation mechanisms. Mater. Sci. Eng. A 488(1–2), 406–414 (2008)

G. Proust, C.N. Tomé, A. Jain, S.R. Agnew, Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy az31. Int. J. Plast. 25(5), 861–880 (2009)

M. Barnett, Twinning and the ductility of magnesium alloys: Part II. “Contraction’’ twins. Mater. Sci. Eng. A 464(1–2), 8–16 (2007)

H. El Kadiri, J. Baird, J. Kapil, A. Oppedal, M. Cherkaoui, S.C. Vogel, Flow asymmetry and nucleation stresses of \(\{{ 1}\,{ 0}\,\bar{{ 1}}\,{ 2}\}\) twinning and non-basal slip in magnesium. Int. J. Plast. 44, 111–120 (2013)

F. Wang, S.R. Agnew, Dislocation transmutation by tension twinning in magnesium alloy az31. Int. J. Plast. 81, 63–86 (2016)

F. Wang, C.D. Barrett, R.J. McCabe, H. El Kadiri, L. Capolungo, S.R. Agnew, Dislocation induced twin growth and formation of basal stacking faults in \(\{{ 1}\,{ 0}\,\bar{{ 1}}\,{ 2}\}\) twins in pure Mg. Acta Mater. 165, 471–485 (2019)

Y. Zhang, P.C. Millett, M. Tonks, B. Biner, Deformation-twin-induced grain boundary failure. Scripta Mater. 66(2), 117–120 (2012)

L. Capolungo, I. Beyerlein, G. Kaschner, C. Tomé, On the interaction between slip dislocations and twins in hcp zr. Mater. Sci. Eng. A 513, 42–51 (2009)

I. Beyerlein, C. Tomé, A probabilistic twin nucleation model for hcp polycrystalline metals. In: Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, p. 20090661 (2010). The Royal Society

P.L. Pratt, S. Pugh, Twin accommodation in zinc. J. Inst. Met. 80, 653–658 (1952)

J.W. Christian, S. Mahajan, Deformation twinning. Prog. Mater. Sci. 39(1–2), 1–157 (1995)

Paudel, Y., Barrett, C.D., El Kadiri, H.: Full-field crystal plasticity modeling of \(\{{\bf 1}\,{\bf 0}\,\bar{{\bf 1}}\,{\bf 2}\}\) twin nucleation. In: Magnesium Technology 2020, p. 141. Springer, (2020)

Y. Paudel, D. Giri, M.W. Priddy, C.D. Barrett, K. Inal, M.A. Tschopp, H. Rhee, H. El Kadiri, A review on capturing twin nucleation in crystal plasticity for hexagonal metals. Metals 11(9), 1373 (2021)

É. Martin, L. Capolungo, L. Jiang, J.J. Jonas, Variant selection during secondary twinning in Mg-3% Al. Acta Mater. 58(11), 3970–3983 (2010)

J.J. Jonas, S. Mu, T. Al-Samman, G. Gottstein, L. Jiang, Ė Martin, The role of strain accommodation during the variant selection of primary twins in magnesium. Acta Mater. 59(5), 2046–2056 (2011)

S. Mu, J.J. Jonas, G. Gottstein, Variant selection of primary, secondary and tertiary twins in a deformed Mg alloy. Acta Mater. 60(5), 2043–2053 (2012)

W.D. Russell, N.R. Bratton, Y. Paudel, R.D. Moser, Z.B. McClelland, C.D. Barrett, A.L. Oppedal, W.R. Whittington, H. Rhee, S. Mujahid et al., In situ characterization of the effect of twin-microstructure interactions on 10–12 tension and 10–11 contraction twin nucleation, growth and damage in magnesium. Metals 10(11), 1403 (2020)

M.A. Kumar, A. Kanjarla, S. Niezgoda, R. Lebensohn, C. Tomé, Numerical study of the stress state of a deformation twin in magnesium. Acta Mater. 84, 349–358 (2015)

M. Arul Kumar, I.J. Beyerlein, R.J. McCabe, C.N. Tome, Grain neighbour effects on twin transmission in hexagonal close-packed materials. Nat. Commun. 7(1), 1–9 (2016)

M.A. Kumar, I.J. Beyerlein, C.N. Tomé, Effect of local stress fields on twin characteristics in hcp metals. Acta Mater. 116, 143–154 (2016)

T. Jin, H.M. Mourad, C.A. Bronkhorst, I.J. Beyerlein, A single crystal plasticity finite element formulation with embedded deformation twins. J. Mech. Phys. Solids 133, 103723 (2019)

M. Ardeljan, M. Knezevic, Explicit modeling of double twinning in az31 using crystal plasticity finite elements for predicting the mechanical fields for twin variant selection and fracture analyses. Acta Mater. 157, 339–354 (2018)

I. Beyerlein, L. Capolungo, P. Marshall, R. McCabe, C. Tomé, Statistical analyses of deformation twinning in magnesium. Philos. Magn. 90(16), 2161–2190 (2010)

J. Cheng, S. Ghosh, Crystal plasticity finite element modeling of discrete twin evolution in polycrystalline magnesium. J. Mech. Phys. Solids 99, 512–538 (2017)

J. Cheng, S. Ghosh, A crystal plasticity Fe model for deformation with twin nucleation in magnesium alloys. Int. J. Plast 67, 148–170 (2015)

Y. Paudel, C.D. Barrett, M.A. Tschopp, K. Inal, H. El Kadiri, Beyond initial twin nucleation in hcp metals: Micromechanical formulation for determining twin spacing during deformation. Acta Mater. 133, 134–146 (2017)

J. Baird, B. Li, S.Y. Parast, S. Horstemeyer, L. Hector Jr., P. Wang, M. Horstemeyer, Localized twin bands in sheet bending of a magnesium alloy. Scripta Mater. 67(5), 471–474 (2012)

Y. Paudel, J. Indeck, K. Hazeli, M.W. Priddy, K. Inal, H. Rhee, C.D. Barrett, W.R. Whittington, K.R. Limmer, H. El Kadiri, Characterization and modeling of \(\{{ 1}\,{ 0}\,\bar{{ 1}}\,{ 2}\}\) twin banding in magnesium. Acta Mater. 183, 438–451 (2020)

H. El Kadiri, J. Kapil, A. Oppedal, L. Hector Jr., S.R. Agnew, M. Cherkaoui, S. Vogel, The effect of twin–twin interactions on the nucleation and propagation of \(\{1\,0\,\bar{1}\, 2\}\) twinning in magnesium. Acta Mater. 61(10), 3549–3563 (2013)

J. Wang, R. Hoagland, J. Hirth, L. Capolungo, I. Beyerlein, C. Tomé, Nucleation of a \(\{\bar{1}\,{0}\,{{1}}\,{2}\}\) twin in hexagonal close-packed crystals. Scripta Mater. 61(9), 903–906 (2009)

J. Wang, J. Hirth, C. Tomé, \(\{\bar{1}\,{0}\,{{1}}\,{2}\}\) twinning nucleation mechanisms in hexagonal-close-packed crystals. Acta Mater. 57(18), 5521–5530 (2009)

J. Wang, I. Beyerlein, C. Tomé, An atomic and probabilistic perspective on twin nucleation in Mg. Scripta Mater. 63(7), 741–746 (2010)

R. Xin, C. Guo, Z. Xu, G. Liu, X. Huang, Q. Liu, Characteristics of long \(\{\)10-12\(\}\) twin bands in sheet rolling of a magnesium alloy. Scripta Mater. 74, 96–99 (2014)

X. Wang, L. Jiang, C. Cooper, K. Yu, D. Zhang, T.J. Rupert, S. Mahajan, I.J. Beyerlein, E.J. Lavernia, J.M. Schoenung, Toughening magnesium with gradient twin meshes. Acta Mater. 195, 468–81 (2020)

Acknowledgments

The authors would like to acknowledge Center for Advanced Vehicular Systems (CAVS), Mississippi State University for their support and resources.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationship that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Appendix

Appendix

The analytical solution to the elliptical integral expressions \(I_i\), and \(I_{ij}\) used to obtain the elastic fields:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Paudel, Y., Barrett, C., Mujahid, S. et al. Micromechanics-based strain energy study of \(\{\textbf{1}\,\textbf{0}\,\bar{\textbf{1}}\,\textbf{2}\}\) twin-band pattern in a three-point bend Mg alloy. Journal of Materials Research 38, 461–472 (2023). https://doi.org/10.1557/s43578-022-00831-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00831-8