Abstract

The lubrication performance of graphene is reduced at high frequencies and speeds owing to the agglomeration and poor interfacial adsorption of graphene. In this study, we used a mild oxidation method to prepare graphene oxide, onto which polar nitrogen-containing groups were grafted to prepare covalently modified graphene. The modified graphene retained a graphene structure and exhibited excellent dispersion stability and interfacial adsorption properties. It was stably dispersed in 500 N base oil for more than 60 days. Tribological tests with a steel ball–steel plate friction system (rate: 75 mm/s; reciprocating frequency: 25 Hz) showed that the friction coefficient of the sliding surface was ~ 0.063 when using 500 N base oil with the modified graphene as a lubricating additive, which was approximately 47.1% lower than that when using pure 500 N base oil.

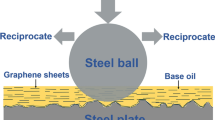

Graphical abstract

Schematic of antifriction mechanism of MG as 500N base oil additive.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

J. Zhao, J. Mao, Y. Li, Y. He, J. Luo, Appl. Surf. Sci. 434, 21 (2018). https://doi.org/10.1016/j.apsusc.2017.10.119

D. Berman, A. Erdemir, A.V. Sumant, Carbon 59, 167 (2013). https://doi.org/10.1016/j.carbon.2013.03.006

P. Restuccia, M.C. Righi, Carbon 106, 118 (2016). https://doi.org/10.1016/j.carbon.2016.05.025

Y. Xu, Y. Peng, T. You, L. Yao, J. Geng, K.D. Dearn, X. Hu, in Nanotechnology in Oil and Gas Industries. ed. by T.A. Saleh (Springer, Cham, 2018), p.151

D. Berman, A. Erdemir, A.V. Sumant, Carbon 54, 454 (2013). https://doi.org/10.1016/j.carbon.2012.11.061

L. Zhao, Z. Cai, Z. Zhang, X. Zhang, Y. Lin, J. Peng, M. Zhu, Chin. J. Mater. Res. 30, 57 (2016). https://doi.org/10.11901/1005.3093.2015.082

Y. Meng, F. Su, Y. Chen, Sci. Rep. 6, 31246 (2016). https://doi.org/10.1038/srep31246

D. Berman, A. Erdemir, A.V. Sumant, Mater. Today 17, 31 (2014). https://doi.org/10.1016/j.mattod.2013.12.003

Y. Qiao, H. Zhao, Y. Zang, Q. Zhang, H. Liu, Chem. Ind. Eng. Prog. 2014(S1), 216 (2014)

K. Lee, Y. Hwang, S. Cheong, L. Kwon, S. Kim, J. Lee, Curr. Appl. Phys. 9, e128 (2009). https://doi.org/10.1016/j.cap.2008.12.054

D. Li, M.B. Müller, S. Gilje, R.B. Kaner, G.G. Wallace, Nat. Nanotechnol. 3, 101 (2008). https://doi.org/10.1038/nnano.2007.451

Y. Si, E.T. Samulski, Nano Lett. 8, 1679 (2008). https://doi.org/10.1021/nl080604h

G. Paul, S. Shit, H. Hirani, T. Kuila, N.C. Murmu, Tribol. Int. 131, 605 (2019). https://doi.org/10.1016/j.triboint.2018.11.012

J. Ding, F. Meng, J. Sui, Z. Meng, Appl. Chem. Ind. 47, 1043–1047 (2018). (in Chinese)

L. Liu, M. Zhou, Y. Mo, P. Bai, Q. Wei, L. Jin, S. You, M. Wang, L. Li, X. Chen, X. Li, Y. Tian, Friction 9, 1568 (2021). https://doi.org/10.1007/s40544-020-0442-8

F. Karlický, K.K.R. Datta, M. Otyepka, R. Zbořil, ACS Nano 7, 6434 (2013). https://doi.org/10.1021/nn4024027

M. Quintana, E. Vazquez, M. Prato, Acc. Chem. Res. 46, 138 (2013). https://doi.org/10.1021/ar300138e

J.M. Englert, C. Dotzer, G. Yang, M. Schmid, C. Papp, J.M. Gottfried, H.-P. Steinrück, E. Spiecker, F. Hauke, A. Hirsch, Nat. Chem. 3, 279 (2011). https://doi.org/10.1038/nchem.1010

P. Di Pietro, G. Forte, R. Snyders, C. Satriano, C. Bittencourt, D. Thiry, Plasma Process. Polym. 17, 2000039 (2020). https://doi.org/10.1002/ppap.202000039

I. Ali, A.A. Basheer, A. Kucherova, N. Memetov, T. Pasko, K. Ovchinnikov, V. Pershin, D. Kuznetsov, E. Galunin, V. Grachev, A. Tkachev, J. Mol. Liq. 279, 251 (2019). https://doi.org/10.1016/j.molliq.2019.01.113

D.D. La, T.N. Truong, T.Q. Pham, H.T. Vo, N.T. Tran, T.A. Nguyen, A.K. Nadda, T.T. Nguyen, S.W. Chang, W.J. Chung, D.D. Nguyen, Nanomaterials 10, 877 (2020). https://doi.org/10.3390/nano10050877

B. Gupta, N. Kumar, K. Panda, A.A. Melvin, S. Joshi, S. Dash, A.K. Tyagi, J. Phys. Chem. C 120, 2139 (2016). https://doi.org/10.1021/acs.jpcc.5b08762

R. Gusain, H.P. Mungse, N. Kumar, T.R. Ravindran, R. Pandian, H. Sugimurac, O.P. Khatri, J. Phys. Chem. A 4, 926 (2016). https://doi.org/10.1039/C5TA08640J

N.A. Ismail, S. Bagheri, Mater. Sci. Eng. B 222, 34 (2017). https://doi.org/10.1016/j.mseb.2017.04.010

S. Choudhary, H.P. Mungse, O.P. Khatri, J. Mater. Chem. 22, 21032 (2012). https://doi.org/10.1039/c2jm34741e

H.P. Mungse, O.P. Khatri, J. Phys. Chem. C 118, 14394 (2014). https://doi.org/10.1021/jp5033614

J. Ma, Y. Xiao, Y. Sun, J. Hu, Y. Wang, Nanoscale Res. Lett. 15, 26 (2020). https://doi.org/10.1186/s11671-020-3257-7

P. Wu, X. Chen, C. Zhang, J. Zhang, J. Luo, J. Zhang, Friction 9, 143 (2021). https://doi.org/10.1007/s40544-019-0359-2

J.W. Suk, R.D. Piner, J. An, R.S. Ruoff, ACS Nano 4, 6557 (2010). https://doi.org/10.1021/nn101781v

Y. Guo, W. Guo, C. Chen, Phys. Rev. B 76, 155429 (2007). https://doi.org/10.1103/PhysRevB.76.155429

F. Bonelli, N. Manini, E. Cadelano, L. Colombo, Eur. Phys. J. B 70, 449 (2009). https://doi.org/10.1140/epjb/e2009-00239-7

L. Bai, N. Srikanth, B. Zhao, B. Liu, Z. Liu, K. Zhou, J. Phys. D: Appl. Phys. 49, 485302 (2016). https://doi.org/10.1088/0022-3727/49/48/485302

L. Liu, M. Zhou, L. Jin, L. Li, Y. Mo, G. Su, X. Li, H. Zhu, Y. Tian, Friction 7, 199 (2019). https://doi.org/10.1007/s40544-019-0268-4

K.A. Wepasnick, B.A. Smith, K.E. Schrote, H.K. Wilson, S.R. Diegelmann, D.H. Fairbrother, Carbon 49, 24 (2011). https://doi.org/10.1016/j.carbon.2010.08.034

W. Cai, R.D. Piner, F.J. Stadermann, S. Park, M.A. Shaibat, Y. Ishii, D. Yang, A. Velamakanni, S.J. An, M. Stoller, J. An, D. Chen, R.S. Ruoff, Science 321, 1815 (2008). https://doi.org/10.1126/science.1162369

S. Chhetri, P. Samanta, N.C. Murmu, S.K. Srivastava, T. Kuila, Polym. Eng. Sci. 56, 1221 (2016). https://doi.org/10.1002/pen.24355

S. Saha, P. Samanta, N.C. Murmu, T. Kuila, Phys. Chem. Chem. Phys. 19, 28588 (2017). https://doi.org/10.1039/C7CP05923J

C.S. Chen, X.H. Chen, L.S. Xu, Z. Yang, W.H. Li, Carbon 43, 1660 (2005). https://doi.org/10.1016/j.carbon.2005.01.044

Funding

This research was supported by the National Natural Science Foundation of China (Grant Number 12062002), Guangxi Natural Science Foundation, China (Grant Number 2022GXNSFFA035036), Scientific Research and Technology Development Program of Guangxi, China (Grant Number AC19245071 and AC20238003), and Liuzhou Science and Technology Plan Project, China (Grant Number 2020NACC0801).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, G., Wang, M., Zhou, M. et al. Application of graphene with excellent dispersion stability and interfacial adsorption properties under high-frequency and high-speed conditions. Journal of Materials Research 37, 4326–4337 (2022). https://doi.org/10.1557/s43578-022-00802-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00802-z