Abstract

The formation of brittle incoherent Fe–Al intermetallics at dissimilar interface makes wire arc additive manufacturing (WAAM) of stainless steel (SS)–aluminium (Al) difficult. The incorporation of nickel (Ni) interlayers between SS and Al is thought to improve structural integrity. This article provides a detailed characterization of SS–Ni and Al–Ni interfaces. The Al-Ni interface is divided into three intermetallic zones: AlNi at center, Al3Ni on Al side, and AlNi3 on Ni side. The Ni3Fe, NiFe, and NiFe3 intermetallics at the SS–Ni interface increase with heat input. The intermetallics at the Al–Ni interface are found to be affected by heat input as well as primary dendrite arm spacing (PDAS) and dendrite growth angle (DGA) of the Ni dendrites. With low heat input, low DGA, and high PDAS, the intermetallic thickness at the Al–Ni interface decreases. It is also discovered that as heat input increases, the hardness of both interfaces increases.

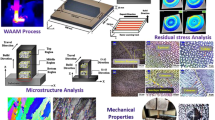

Graphical abstract

Similar content being viewed by others

Data availability

There is no need for a separate archive since the manuscript contains all the details needed to reproduce the work.

References

A.C.M. Bekker, J.C. Verlinden, G. Galimberti, Challenges in assessing the sustainability of wire + arc additive manufacturing for large structures. Int. Solid Free Fabr. Symp. An Addit. Manuf. Conf. SFF 1, 406–416 (2016)

P. Colegrove, High deposition rate high quality metal additive manufacture using wire + arc technology, Cranf. Univ. (2010).

A.R. Paul, M. Mukherjee, M. Raja, S. Kundu, A. Chatterjee, Development of near homogeneous properties in wire arc additive manufacturing process for near-net shaped structural component of low-carbon steel. Proc. Inst. Mech. Eng. Part C 236, 3497–3511 (2022)

J. Wanwan, Z. Chaoqun, J. Shuoya, T. Yingtao, W. Daniel, L. Wen, Wire arc additive manufacturing of stainless steels: a review. Appl. Sci. 10, 1563 (2020)

K.S. Derekar, A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 34, 895–916 (2018)

B. Dong, Z. Pan, C. Shen, Y. Ma, H. Li, Fabrication of copper-rich Cu-Al alloy using the wire-arc additive manufacturing process. Metall. Mater. Trans. B 48, 3143–3151 (2017)

F. Veiga, A.G. Del Val, A. Suárez, U. Alonso, Analysis of the machining process of titanium Ti6Al-4V parts manufactured by wire arc additive manufacturing (WAAM). Materials 13, 15 (2020)

R. Karunakaran, S. Ortgies, A. Tamayol, F. Bobaru, M.P. Sealy, Additive manufacturing of magnesium alloys. Bioact. Mater. 5, 44–54 (2020)

X. Xu, J. Ding, S. Ganguly, S. Williams, Investigation of process factors affecting mechanical properties of Inconel 718 superalloy in wire + arc additive manufacture process. J. Mater. Process. Technol. 265, 201–209 (2019)

A.R. Paul, M. Mukherjee, D. Singh, A critical review on the properties of intermetallic compounds and their application in the modern manufacturing. Cryst. Res. Technol. 57, 1–19 (2022)

Y. Tian, J. Shen, S. Hu, J. Gou, E. Kannatey-Asibu, Wire and arc additive manufactured Ti–6Al–4V/Al–625Cu dissimilar alloys by CMT-welding: effect of deposition order on reaction layer. Sci. Technol. Weld. Join. 25, 73–80 (2020)

G. Marinelli, F. Martina, H. Lewtas, D. Hancock, S. Ganguly, S. Williams, Functionally graded structures of refractory metals by wire arc additive manufacturing. Sci. Technol. Weld. Join. 24, 495–503 (2019)

T. Abe, H. Sasahara, Dissimilar metal deposition with a stainless steel and nickel-based alloy using wire and arc-based additive manufacturing. Precis. Eng. 45, 387–395 (2016)

C. Shen, Z. Pan, D. Cuiuri, D. Ding, H. Li, Influences of deposition current and interpass temperature to the Fe3Al-based iron aluminide fabricated using wire-arc additive manufacturing process. Int. J. Adv. Manuf. Technol 88, 2009–2018 (2017)

G. Sierra, P. Peyre, F.D. Beaume, D. Stuart, G. Fras, Galvanised steel to aluminium joining by laser and GTAW processes. Mater. Charact. 59, 1705–1715 (2008)

Y. Su, X. Hua, Y. Wu, Effect of input current modes on intermetallic layer and mechanical property of aluminum-steel lap joint obtained by gas metal arc welding. Mater. Sci. Eng. A 578, 340–345 (2013)

H.J. Yi, J.W. Kim, Y.L. Kim, S. Shin, Effects of cooling rate on the microstructure and tensile properties of wire-arc additive manufactured Ti–6Al–4V alloy. Met. Mater. Int. 26, 1235–1246 (2020)

O. Grong, Metallurgical modelling of welding, 1st edn. (The institute of materials, UK, 1994).

W.D. Callister, Fundamentals of Materials Science and Engineering: an Integrated Approach, 6th edn. (Willey, New York, 2019)

D. Das, D.K. Pratihar, G.G. Roy, Establishing a correlation between residual stress and natural frequency of vibration for electron beam butt weld of AISI 304 stainless steel. Arab. J. Sci. Eng. 45, 5769–5781 (2020)

G. Phanikumar, P. Dutta, K. Chattopadhyay, Continuous welding of Cu-Ni dissimilar couple using CO2 laser. Sci. Technol. Weld. Join. 10, 158–166 (2005)

K.S. Kumar, G. Phanikumar, P. Dutta, K. Chattopadhyay, Microstructural development of dissimilar weldments: Case of MiG welding of Cu with Fe filler. J. Mater. Sci. 37, 2345–2349 (2002)

M. Mukherjee, T.K. Pal, Evaluation of microstructural and mechanical properties of Fe-16Cr-1Ni-9Mn-012N austenitic stainless steel welded joints. Mater. Charact. 131, 406–424 (2017)

G. Saad, S.A. Fayek, A. Fawzy, H.N. Soliman, G. Mohammed, Deformation characteristics of Al-4043 alloy. Mater. Sci. Eng. A 15, 904–910 (2010)

V.D. ThyssenKrupp, Nicrofer 6025 HT–alloy 602 CA. Mater. Data Sheet 4037, 2–5 (2007)

Acknowledgments

The authors would like to acknowledge the DST-SERB for the financial support (Sanction No. ECR/2018/001250) to carry out the research activities. The authors would also like to acknowledge Director, CSIR-CMERI, for providing the opportunity, and facilities to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflicts of interest that could have influenced the research presented in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Paul, A.R., Mukherjee, M., Singh, D. et al. Interfacial characterization of additively manufactured stainless steel to aluminium thin wall with nickel interlayer. Journal of Materials Research 37, 3629–3645 (2022). https://doi.org/10.1557/s43578-022-00732-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00732-w