Abstract

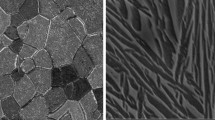

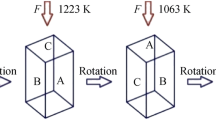

Metastable β-type Ti–38Nb–0.2O alloy was subjected to cold rolling (CR) and solution treatment (ST), and the effects of initial microstructure on the aging behavior and subsequent mechanical properties were investigated. High density of dislocations and grain refinement were introduced by CR, which suppressed the ω phase and promoted the α phase in the subsequent aging process. Upon aging at 573 K, the CR specimen consisted of α + β phase and high density of dislocations, while the ST specimen showed homogeneous precipitation of ω phase. Upon aging at 773 K, the CR specimen exhibited ultrafine equiaxed α phase without obvious β grain boundary, while the ST specimen contained acicular α precipitates nonuniformly distributed in the internal grain and grain boundary, and precipitate-free zone near grain boundaries were observed. The different initial microstructures led to large difference in strength and Young’s modulus between the aged specimens.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

D. Banerjee, J.C. Williams, Perspectives on titanium science and technology. Acta Mater. 61(3), 844 (2013)

M. Bonisch, M. Calin, J. van Humbeeck, W. Skrotzki, J. Eckert, Factors influencing the elastic moduli, reversible strains and hysteresis loops in martensitic Ti–Nb alloys. Mater. Sci. Eng. C Mater. Biol. Appl. 48, 511 (2015)

J.Y. Zhang, G.F. Chen, Y.Y. Fu, Y. Fan, Z. Chen, J. Xu, H. Chang, Z.H. Zhang, J. Zhou, Z. Sun, B.L. Shen, F. Sun, Strengthening strain-transformable β Ti-alloy via multi-phase nanostructuration. J. Alloy. Compd. 799, 389 (2019)

F. Sun, Y.L. Hao, J.Y. Zhang, F. Prima, Contribution of nano-sized lamellar microstructure on recoverable strain of Ti–24Nb–4Zr–7.9Sn titanium alloy. Mater. Sci. Eng. A 528(25–26), 7811 (2011)

W. Chen, S. Cao, W. Kou, J. Zhang, Y. Wang, Y. Zha, Y. Pan, Q. Hu, Q. Sun, J. Sun, Origin of the ductile-to-brittle transition of metastable β-titanium alloys: self-hardening of ω-precipitates. Acta Mater. 170, 187 (2019)

J.W. Foltz, B. Welk, P.C. Collins, H.L. Fraser, J.C. Williams, Formation of grain boundary α in β Ti alloys: its role in deformation and fracture behavior of these alloys. Metall. Mater. Trans. A 42(3), 645 (2010)

Y. Fu, W. Xiao, J. Wang, L. Ren, X. Zhao, C. Ma, A novel strategy for developing α + β dual-phase titanium alloys with low young’s modulus and high yield strength. J. Mater. Sci. Technol. 76, 122–128 (2020)

E.M. Hildyard, L.D. Connor, L.R. Owen, D. Rugg, N. Martin, H.J. Stone, N.G. Jones, The influence of microstructural condition on the phase transformations in Ti–24Nb (at.%). Acta Mater. 199, 129 (2020)

H. Wang, S.-W. Xin, Y.-Q. Zhao, W. Zhou, W.-D. Zeng, Forging–microstructure–tensile properties correlation in a new near β high-strength titanium alloy. Rare Met. 40(8), 2109 (2020)

D.L. Moffat, D.C. Larbalestier, The compctition between the alpha and omega phases in aged Ti–Nb alloys. Metall. Trans. A 19(7), 1687 (1988)

A. Berg, J. Kiese, L. Wagner, Microstructural gradients in Ti–3Al–8V–6Cr–4Zr–4Mo for excellent HCF strength and toughness. Mater. Sci. Eng. A 243(1), 146 (1998)

B. Jiang, S. Emura, K. Tsuchiya, Microstructural evolution and its effect on the mechanical behavior of Ti–5Al–5Mo–5V–3Cr alloy during aging. Mater. Sci. Eng. A 731, 239 (2018)

S. Guo, Q. Meng, G. Liao, L. Hu, X. Zhao, Microstructural evolution and mechanical behavior of metastable β-type Ti–25Nb–2Mo–4Sn alloy with high strength and low modulus. Prog. Nat. Sci. Mater. Int. 23(2), 174 (2013)

S. Guo, Q. Meng, L. Hu, G. Liao, X. Zhao, H. Xu, Suppression of isothermal ω phase by dislocation tangles and grain boundaries in metastable β-type titanium alloys. J. Alloy. Compd. 550, 35 (2013)

S. Guo, Z. Bao, Q. Meng, L. Hu, X. Zhao, A novel metastable Ti–25Nb–2Mo–4Sn alloy with high strength and low young’s modulus. Metall. Mater. Trans. A 43(10), 3447 (2012)

M. Yan, W. Xu, M.S. Dargusch, H.P. Tang, M. Brandt, M. Qian, Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall. 57(4), 251 (2014)

J.I. Kim, H.Y. Kim, H. Hosoda, S. Miyazaki, Shape memory behavior of Ti–22Nb–(0.5–2.0) O (at%) biomedical alloys. Mater. Trans. 46(4), 852 (2005)

T. Saito, T. Furuta, J.H. Hwang, S. Kuramoto, K. Nishino, N. Suzuki, R. Chen, A. Yamada, K. Ito, Y. Seno, T. Nonaka, H. Ikehata, N. Nagasako, C. Iwamoto, Y. Ikuhara, T. Sakuma, Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism. Science 300(5618), 464 (2003)

Y.L. Hao, Z.B. Zhang, S.J. Li, R. Yang, Microstructure and mechanical behavior of a Ti–24Nb–4Zr–8Sn alloy processed by warm swaging and warm rolling. Acta Mater. 60(5), 2169 (2012)

S. Hanada, N. Masahashi, T.K. Jung, Effect of stress-induced α″ martensite on Young’s modulus of β Ti–33.6Nb–4Sn alloy. Mater. Sci. Eng. A 588, 403 (2013)

C.M. Liu, H.M. Wang, X.J. Tian, H.B. Tang, Subtransus triplex heat treatment of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Mater. Sci. Eng. A 590, 30 (2014)

J.I. Qazi, V. Tsakiris, B. Marquardt, H.J. Rack, Effect of aging treatments on the tensile properties of Ti–35Nb–7Zr–5Ta–(00.6–0.7)O alloys. J. ASTM Int. 2(8), 12780 (2005)

J.I. Kim, H.Y. Kim, T. Inamura, H. Hosoda, S. Miyazaki, Effect of annealing temperature on microstructure and shape memory characteristics of Ti–22Nb–6Zr(at%) biomedical alloy. Mater. Trans. 47(3), 505 (2006)

W.-T. Qu, H. Gong, J. Wang, Y.-S. Nie, Y. Li, Martensitic transformation, shape memory effect and superelasticity of Ti–xZr–(30–x)Nb–4Ta alloys. Rare Met. 38(10), 965 (2019)

Q. Meng, S. Guo, Q. Liu, L. Hu, X. Zhao, A β-type TiNbZr alloy with low modulus and high strength for biomedical applications. Prog. Nat. Sci. Mater. Int. 24(2), 157 (2014)

M. Tahara, H.Y. Kim, T. Inamura, H. Hosoda, S. Miyazaki, Role of interstitial atoms in the microstructure and non-linear elastic deformation behavior of Ti–Nb alloy. J. Alloy. Compd. 577, S404 (2013)

Y.L. Hao, S.J. Li, S.Y. Sun, C.Y. Zheng, Q.M. Hu, R. Yang, Super-elastic titanium alloy with unstable plastic deformation. Appl. Phys. Lett. 87(9), 091906 (2005)

J.P. Cui, Y.L. Hao, S.J. Li, M.L. Sui, D.X. Li, R. Yang, Reversible movement of homogenously nucleated dislocations in a beta-titanium alloy. Phys Rev Lett. 102(4), 045503 (2009)

T. Furuta, S. Kuramoto, J. Hwang, K. Nishino, T. Saito, Elastic deformation behavior of multi-functional Ti–Nb–Ta–Zr–O Alloys. Mater. Trans. 46(12), 3001 (2005)

S. Nag, R. Banerjee, R. Srinivasan, J.Y. Hwang, M. Harper, H.L. Fraser, ω-Assisted nucleation and growth of α precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy. Acta Mater. 57(7), 2136 (2009)

L.M. Hsiung, D.H. Lassila, Shock-induced deformation twinning and omega transformation in tantalum and tantalum–tungsten alloys. Acta Mater. 48(20), 4851 (2000)

T. Richeton, J. Weiss, F. Louchet, Dislocation avalanches: role of temperature, grain size and strain hardening. Acta Mater. 53(16), 4463 (2005)

B. Jiang, S. Emura, K. Tsuchiya, Formation of equiaxed α phase in Ti–5Al–5Mo–5V–3Cr alloy deformed by high-pressure torsion. J. Alloy. Compd. 738, 283 (2018)

S. Zherebtsov, G. Salishchev, S. Lee Semiatin, Loss of coherency of the alpha/beta interface boundary in titanium alloys during deformation. Philos. Mag. Lett. 90(12), 903 (2010)

T. Furuhara, T. Makino, Y. Idei, H. Ishigaki, A. Takada, T. Maki, Morphology and crystallography of α precipitates in β Ti–Mo binary alloys. Mater. Trans. 39(1), 31 (1998)

A. Zafari, K. Xia, Formation of equiaxed α during ageing in a severely deformed metastable β Ti alloy. Scripta Mater. 124, 151 (2016)

K. Bartha, J. Stráský, A. Veverková, P. Barriobero-Vila, F. Lukáč, P. Doležal, P. Sedlák, V. Polyakova, I. Semenova, M. Janeček, Effect of the high-pressure torsion (HPT) and subsequent isothermal annealing on the phase transformation in biomedical Ti15Mo alloy. Metals 9(11), 1194 (2019)

M. Ahmed, D. Wexler, G. Casillas, O.M. Ivasishin, E.V. Pereloma, The influence of β phase stability on deformation mode and compressive mechanical properties of Ti–10V–3Fe–3Al alloy. Acta Mater. 84, 124 (2015)

S.A. Mantri, D. Choudhuri, T. Alam, V. Ageh, F. Sun, F. Prima, R. Banerjee, Change in the deformation mode resulting from beta-omega compositional partitioning in a Ti Mo alloy: room versus elevated temperature. Scripta Mater. 130, 69 (2017)

M.J. Lai, T. Li, D. Raabe, ω phase acts as a switch between dislocation channeling and joint twinning- and transformation-induced plasticity in a metastable β titanium alloy. Acta Mater. 151, 67 (2018)

A. Melander, P.Å. Persson, The strength of a precipitation hardened AlZnMg alloy. Acta Metall. 26(2), 267 (1978)

J. Sun, Q. Yao, H. Xing, W.Y. Guo, Elastic properties of β, α′′ and ω metastable phases in Ti–Nb alloy from first-principles. J. Phys. Condens. Matter 19(48), 486215 (2007)

J.M. Rosenberg, H.R. Piehler, Calculation of the Taylor factor and lattice rotations for bcc metals deforming by pencil glide. Metall. Trans. 2(1), 257 (1971)

N. Chen, H. Kou, Z. Wu, F. Qiang, C. Wang, J. Li, J.M. Molina-Aldareguia, Stress-induced α″ martensitic phase transformation and martensitic twinning in a metastable β titanium alloy. J. Alloys Compd. 859, 157809 (2021)

J. Dong, F. Li, C. Wang, Micromechanical behavior study of α phase with different morphologies of Ti–6Al–4V alloy by microindentation. Mater. Sci. Eng. A 580, 105 (2013)

Acknowledgments

The authors gratefully acknowledge the funding of the National Natural Science Foundation of China (NSFC, No. 51671012) and the National Natural Science Foundation of China (NSFC, No.52001018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, J., Xiao, W., Fu, Y. et al. Effects of initial microstructure on the aging behavior and subsequent mechanical properties of Ti–Nb–O titanium alloy. Journal of Materials Research 37, 2304–2313 (2022). https://doi.org/10.1557/s43578-022-00631-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00631-0