Abstract

Dental implants are commonly manufactured by shaping titanium rods into screws in an oil medium followed by sandblasting. This study compares the biocompatibility of the titanium dental implants machined in an oil versus DI-water environment. Electrochemical evaluations showed that the machining oil leaves residue on the implant. As a remedy, chemical mechanical nano-structuring (CMNS) is implemented to remove oil residue while controlling the surface roughness and surface passivation. Bacteria growth on the oil-machined and sandblasted implants was higher than the implants only machined in oil (p value 0.014) and DI water (p value 0.002). Cytotoxicity experiments also showed ~ 5% higher cell concentration on the DI-water-machined implants than the oil-machined implants and ~ 10% higher than the oil-machined/sandblasted implants. After CMNS treatment, both the DI-water and oil-machined implants showed statistically the same cell proliferation (p value 0.785), indicating that the implants were cleaned from the oil residue.

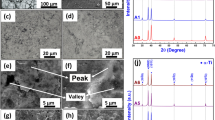

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request. In addition, the datasets generated during and/or analyzed during the current study are available in the [JMR Data Files] repository in the following link: https://1drv.ms/u/s!AmMSRf5PldcHhUpQ0Zhd0UhwOOmL?e=5o3oYR.

References

M.Y. Chin, A. Sandham, J. de Vries, H.C. van der Mei, H.J. Busscher, Biofilm formation on surface characterized micro-implants for skeletal anchorage in orthodontics. Biomaterials 28(11), 2032–2040 (2007). https://doi.org/10.1016/j.biomaterials.2006.12.014

H. Kim, S.H. Choi, J.J. Ryu, S.Y. Koh, J.H. Park, I.S. Lee, The biocompatibility of SLA-treated titanium implants. Biomed. Mater. 3(2), 025011 (2008). https://doi.org/10.1088/1748-6041/3/2/025011

J. Li, Y. Zhao, Biocompatibility and antibacterial performance of titanium by surface treatment. J. Coat. Technol. Res. 9, 223–228 (2012). https://doi.org/10.1007/s11998-009-9221-1

E. Unosson, Antibacterial strategies for titanium biomaterials. Digital comprehensive summaries of Uppsala Dissertations from the Faculty of Science and Technology, 1250. ISSN 1651-6214, 2015

L. Damiati, M.G. Eales, A.H. Nobbs, B. Su, P.M. Tsimbouri, M. Salmeron-Sanchez, M.J. Dalby, Impact of surface topography and coating on osteogenesis and bacterial attachment on titanium implants. J. Tissue Eng. (2018). https://doi.org/10.1177/2041731418790694

F. Variola, J. Yi, L. Richert, J. Wuest, F. Rosei, A. Nanci, Tailoring the surface properties of Ti6Al4V by controlled chemical oxidation. Biomaterials 29(10), 1285–1298 (2008). https://doi.org/10.1016/j.biomaterials.2007.11.040

C. Yifan, F. Guoping, M. Carmen, Micro- and nanotopography sensitive bacterial attachment mechanisms: a review. Front. Microbiol. (2019). https://doi.org/10.3389/fmicb.2019.00191

C. Sittig, M. Textor, N.D. Spencer, M. Wieland, P.H. Vallotton, Surface characterization of implant materials c.p. Ti, Ti–6Al–7Nb and Ti–6Al–4V with different pretreatments. J. Mater. Sci. Mater. Med. 10(1), 35–46 (1999). https://doi.org/10.1023/a:1008840026907

V. Pivodova, J. Frankova, J. Ulrichova, Osteoblast and gingival fibroblast markers in dental implant studies. Biomed. Pap. Med. Fac. Univ. Palacky Olomouc Czechoslov. 155(2), 109–116 (2011). https://doi.org/10.5507/bp.2011.021

G. Bhardwaj, T.J. Webster, Reduced bacterial growth and increased osteoblast proliferation on titanium with a nanophase TiO2 surface treatment. Int. J. Nanomed. 12, 363–369 (2017). https://doi.org/10.2147/IJN.S116105

K. Beers, D. Sur, G.B. Basim, Chemical mechanical surface nano-structuring (CMNS) implementation on titanium based implants to enhance corrosion resistance and control biocompatibility. MRS Adv. 5(43), 2209–2219 (2020). https://doi.org/10.1557/adv.2020.325

H. Kim, S.H. Choi, J.J. Ryu, S.Y. Koh, J.H. Park, I.S. Lee, The biocompatibility of SLA-treated titanium implants. Biomed. Mater. (Bristol, England) (2008). https://doi.org/10.1088/1748-6041/3/2/025011

Z. Ozdemir, A. Ozdemir, G.B. Basim, Application of chemical mechanical polishing process on titanium-based implants. Mater. Sci. Eng. C 68, 383–396 (2016). https://doi.org/10.1016/j.msec.2016.06.002

M.B. Rosa, T. Albrektsson, C.E. Francischone, H.O. Schwartz Filho, A. Wennerberg, The influence of surface treatment on the implant roughness pattern. J. Appl. Oral Sci. 20(5), 550–555 (2012). https://doi.org/10.1590/s1678-77572012000500010

D.C. Rodrigues, P. Valderrama, T.G. Wilson, K. Palmer, A. Thomas, S. Sridhar, A. Adapalli, M. Burbano, C. Wadhwani, Titanium corrosion mechanisms in the oral environment: a retrieval study. Materials (Basel, Switzerland) 6(11), 5258–5274 (2013). https://doi.org/10.3390/ma6115258

R. Smeets, B. Stadlinger, F. Schwarz, B. Beck-Broichsitter, O. Jung, C. Precht, F. Kloss, A. Gröbe, M. Heiland, T. Ebker, Impact of dental implant surface modifications on osseointegration. Biomed. Res. Int. (2016). https://doi.org/10.1155/2016/6285620

R. Delgado-Ruiz, G. Romanos, Potential causes of titanium particle and ion release in implant dentistry: a systematic review. Int. J. Mol. Sci. 19(11), 3585 (2018). https://doi.org/10.3390/ijms19113585

A.T. Sidambe, Biocompatibility of advanced manufactured titanium implants—a review. Materials (Basel, Switzerland) 7(12), 8168–8188 (2014). https://doi.org/10.3390/ma7128168

P. Jakupi, D. Zagidulin, J.J. Noël, D.W. Shoesmith, The impedance properties of the oxide film on the Ni–Cr–Mo alloy-22 in neutral concentrated sodium chloride solution. Electrochim. Acta 56(17), 6251–6259 (2011). https://doi.org/10.1016/j.electacta.2010.07.064

D. Klotz, Negative capacitance or inductive loop?—a general assessment of a common low frequency impedance feature. Electrochem. Commun. 98, 58–62 (2019). https://doi.org/10.1016/j.elecom.2018.11.017

J. Bessone, C. Mayer, K. Jüttner, W.J. Lorenz, AC-impedance measurements on aluminium barrier type oxide films. Electrochim. Acta 28(2), 171–175 (1983). https://doi.org/10.1016/0013-4686(83)85105-6

M.H. Kim, K. Park, K.H. Choi, S.H. Kim, S.E. Kim, C.M. Jeong, J.B. Huh, Cell adhesion and in vivo osseointegration of sandblasted/acid etched/anodized dental implants. Int. J. Mol. Sci. 16(5), 10324–10336 (2015). https://doi.org/10.3390/ijms160510324

F.S. Rhenus 750, Rhenus Lub GmbH Co KG, Mönchengladbach, Ger. 2006(1907), 1–13 (2015)

A. Martini, B.S. Moricz, A.K. Ripperger, P.M. Tran, M.E. Sharp, A.N. Forsythe, S.W. Kulhankova, W. Salgado-Pabon, B.D. Jones, Association of novel Streptococcus sanguinis virulence factors with pathogenesis in a native valve infective endocarditis model. Front. Microbiol. 11, (2020). https://doi.org/10.3389/fmicb.2020.00010

G.B. Basim, O. Bebek, The method of processing multidimensional objects using chemical and mechanical polishing method and configuration of robotic arm employed in realizing this method. PCT Patent Office Application No: PCT/TR2014/000530, Application Date 31 Dec 2014

T. Kokubo, H. Takadama, How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27(15), 2907–2915 (2006). https://doi.org/10.1016/j.biomaterials.2006.01.017

Acknowledgments

The authors would like to acknowledge the MODE Medikal for providing the dental implants, Versum Materials for providing the polishing slurry, and the research funding and facilities provided by the NSF I/UCRC Center for Particle and Surfactant Systems (NSF Grant No 1362060) and discussions with Prof. Brij Moudgil. Also, we thank Jacqueline Cicalese with Dr. G. Bahar Basim’s research group for surface roughness measurements. Images were created with BioRender.com.

Author information

Authors and Affiliations

Contributions

NE has conducted the CMNS experiments, bacteria and cytotoxicity tests, and analyses. DS has conducted the electrochemical evaluations and data analyses. GBB initiated the research work and constructed the experimental analyses structure with organization of the manuscript and the foundation of the research work. The authors discussed the results and contributed to the writing of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare(s) that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Erwin, N., Sur, D. & Basim, G.B. Remediation of machining medium effect on biocompatibility of titanium-based dental implants by chemical mechanical nano-structuring. Journal of Materials Research 37, 2686–2697 (2022). https://doi.org/10.1557/s43578-022-00553-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00553-x