Abstract

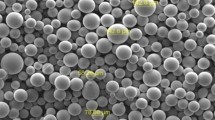

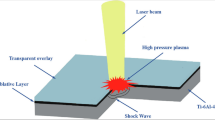

Ti65 samples without obvious defects were successfully prepared by laser deposition manufacturing (LDM), followed by different heat treatments. The microstructures and mechanical properties of the as-deposited and heat-treated samples were investigated. Results showed that the as-deposited microstructure was lamellar structure with precipitations of spherical S2 silicide, tungsten-rich phase and granular Ti3Sn. After annealing, the microstructure turned into a basket-weave microstructure, the volume fraction of silicide was reduced, the tungsten-rich phase was dissolved and more granular Ti3Sn phases with smaller sizes were distributed at the phase boundaries contributing to the improvement of tensile strength and plasticity. After solid-solution plus aging, a duplex microstructure appeared, intragranular α lath was spheroidized, the volume fraction of silicide was minimal and the Ti3Sn phase disappeared, leading to a greater improvement of plasticity and decreasing of tensile strength. Annealing and solid-solution plus aging both enhanced the microhardness of the laser deposited Ti65 sample.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Y.Y. Zhu, X.J. Tian, J. Li, H.M. Wang, Microstructure evolution and layer bands of laser melting deposition Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. J. Alloys Compd. 616, 468 (2014)

C. Ding, Q. Shi, X. Liu, L. Zheng, R.X. Li, Z.X. Hang, B.Y. Yu, W. Wu, Microstructure and mechanical properties of PM Ti600 alloy after hot extrusion and subsequent annealing treatment. Mater. Sci. Eng. A 748, 434 (2019)

J.Q. Wang, J.R. Liu, R. Yang, Present situation and prospect of high temperature titanium alloy. J. Aeronaut. Mater. 34, 26 (2014). (in Chinese)

R.F. Han, J.Y. Li, L.Y. Kong, J.R. Liu, X.R. Shan, X.Y. Cui, A novel phosphate-ceramic coating for high temperature oxidation resistance of Ti65 alloys. Ceram. Int. 45, 23895 (2019)

Y.R. Han, C.H. Zhang, X. Cui, S. Zhang, J. Chen, S.Y. Dong, A.O. Abdullah, Microstructure and properties of a novel wear- and corrosion-resistant stainless steel fabricated by laser melting deposition. J. Mater. Res. 35, 2006 (2020)

Y. Zhai, D.A. Lados, J.L. LaGoy, Additive manufacturing: making imagination the major limitation. JOM 66, 808 (2014)

L.Y. Qin, J.H. Men, L.S. Zhang, S. Zhao, C.F. Li, G. Yang, Microstructure homogenizations of Ti–6Al–4V alloy manufactured by hybrid selective laser melting and laser deposition manufacturing. Mater. Sci. Eng. A 759, 404 (2019)

R.Z. Yu, Z.Y. Zhu, B. Li, Y.Z. Lu, B.W. Fu, X. Lu, Performance improvement of laser additive manufactured Cu-Cr alloy via continuous extrusion. J. Alloys Compd. 879, 160475 (2021)

R.J. Vikram, A. Singh, S. Suwas, Effect of heat treatment on the modification of microstructure of selective laser melted (SLM) IN718 and its consequences on mechanical behavior. J. Mater. Res. 35, 1949 (2020)

W. Yang, Z.S. Quan, T.X. Jun, W.H. Ming, High-cycle fatigue crack initiation and propagation in laser melting deposited TC18 titanium alloy. Int. J. Miner. Metall. Mater. 20, 665 (2013)

Z.X. Zhang, J.K. Fan, R.F. Li, H.C. Kou, Z.Y. Chen, Q.J. Wang, H.L. Zhang, J. Wang, Q. Gao, J.S. Li, Orientation dependent behavior of tensile-creep deformation of hot rolled Ti65 titanium alloy sheet. J. Mater. Sci. Technol. 75, 265 (2021)

X.Y. Zhang, C.W. Li, M.Y. Zheng, H.Z. Zhong, J.F. Gu, Alternative-band microstructure and LPSO phase in TiAl alloy produced by direct laser deposition. Mater. Charact. 164, 110315 (2020)

P. Qi, B.L. Li, T.B. Wang, L. Zhou, Z.R. Ni, Evolution of microstructural homogeneity in novel Ti–6Zr–5Fe alloy fabricated by selective laser melting. Mater. Charact. 171, 110729 (2021)

W.Y. Li, Z.Y. Chen, J.R. Liu, S.X. Zhu, G.X. Sui, Q.J. Wang, Rolling texture and its effect on tensile property of a near-α titanium alloy Ti60 plate. J. Mater. Sci. Technol. 35, 790 (2019)

J. Liu, T.L. Wu, M.F. Wang, L. Wang, Q. Zhou, K.H. Wang, P. Staron, N. Schell, N. Huber, N. Kashaev, In situ observation of competitive growth of α grains during β → α transformation in laser beam manufactured TiAl alloys. Mater. Charact. 179, 111371 (2021)

M.Y. Zheng, C.W. Li, X.Y. Zhang, Z.H. Ye, X.D. Yang, J.F. Gu, The influence of columnar to equiaxed transition on deformation behavior of FeCoCrNiMn high entropy alloy fabricated by laser-based directed energy deposition. Addit. Manuf. 37, 101660 (2021)

T. Amine, W. Joseph, L. Frank, Methodology for studying effect of cooling rate during laser deposition on microstructure. J. Mater. Eng. Perform. 24, 3129 (2015)

H.G. Li, Y.J. Huang, S.S. Jiang, Y.Z. Lu, X.Y. Gao, X. Lu, Z.L. Ning, J.F. Sun, Columnar to equiaxed transition in additively manufactured CoCrFeMnNi high entropy alloy. Mater. Des. 197, 1275 (2021)

Z. Ding, J.K. Fan, Z.X. Zhang, X.D. Liu, J.Q. Wang, Z.Y. Chen, Microstructure and texture variations in high temperature titanium alloy Ti65 sheets with different rolling modes and heat treatments. Materials 13, 2466 (2020)

K. Yue, J.R. Liu, S.X. Zhu, L. Wang, Q.J. Wang, R. Yang, Origins of different tensile behaviors induced by cooling rate in a near alpha titanium alloy Ti65. Materials 1, 128 (2018)

Q.F. Liu, C.J. Chen, M. Zhang, S.Q. Wang, Effect of different heat treatments on the microstructural evolution and mechanical properties of Ni–Cr–Si alloy fabricated by laser additive manufacturing. J. Mater. Eng. Perform. 28, 4543 (2019)

Y. Cao, Study on grain boundary characteristics and precipitated phase transformation of IN718 alloy made by laser hardening. PhD Dissertation, Inner Mongolia University of Technology (2021) (in Chinese)

Z.P. Tong, X.D. Ren, J.F. Jiao, W.F. Zhou, Y.P. Ren, Y.X. Ye, E.A. Larson, J.Y. Gu, Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: effect of heat treatment on microstructure, residual stress and mechanical property. J. Alloys Compd. 785, 1144 (2019)

T.T. Qian, D. Liu, X.J. Tian, C.M. Liu, H.M. Wang, Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process. Trans. Nonferr. Met. Soc. China 24, 2729 (2014)

X.D. Li, J.Z. Liu, Y.Y. Cheng, X. Liu, D. Zhang, Solid-state phase transformation of TC11 titanium during unstable thermal cycling in laser melting deposition process. J. Iron Steel Res. Int. 26, 743 (2019)

V. Venkatesh, A. Wilson, M. Kamal, M. Thomas, D. Lambert, Computational modeling in the primary processing of titanium: a review. JOM 61, 45 (2009)

J.W. Xu, W.D. Zeng, X.Y. Zhang, D.D. Zhou, Analysis of globalizations modeling and mechanisms of alpha/beta titanium alloy. J. Alloys Compd. 788, 110 (2019)

N. Stefansson, S.L. Semiatin, Prediction of the kinetics of static globalizations of Ti–6Al–4V. Metall. Mater. Trans. A 36, 1372 (2005)

N. Stefansson, S.L. Semiatin, Mechanisms of globalizations of Ti–6Al–4V during static heat treatment. Metall. Mater. Trans. A 36, 691 (2003)

Z.X. Zhang, J.K. Fan, Z.H. Wu, D. Zhao, Q. Gao, Q.B. Wang, Z.Y. Chen, Precipitation behavior and strengthening-toughening mechanism of hot rolled sheet of Ti65 titanium alloy during aging process. J. Alloys Compd. 831, 154786 (2020)

D.B. Lee, S.W. Woo, High temperature oxidation mechanism of TiAl–W–Si alloys. Mater. Sci. Forum 449, 8178 (2004)

O. Vdovychenko, O. Ivanova, Y. Podrezov, M. Bulanova, I. Fartushna, Mechanical behavior of homogeneous and nearly homogeneous Ti3Sn: role of composition and microstructure. Mater. Des. 125, 26 (2017)

Q. Zhang, J. Chen, H. Tan, X. Lin, W.D. Huang, Microstructure evolution and mechanical properties of laser additive manufactured Ti–5Al–2Sn–2Zr–4Mo–4Cr alloy. Trans. Nonferr. Met. Soc. China 26, 2058 (2016)

W. Liu, X.Y. Ren, N. Li, C. Gao, H.P. Xiong, Rapid directionally solidified microstructure characteristic and fracture behaviour of laser melting deposited Nb–Si–Ti alloy. Prog. Nat. Sci. Mater. 31, 113 (2021)

Acknowledgments

The work was supported by the National Key Research and Development Program of China (Grant No. 2017YFB1104002) and the Central Guidance on Local Science and Technology Development Fund of Liaoning Province (Grant No. 2022JH6/100100041).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

He, B., Sun, J., Ren, Y. et al. Effect of heat treatment on microstructure and mechanical properties of laser-deposited Ti65 near-alpha titanium alloy. Journal of Materials Research 37, 1464–1474 (2022). https://doi.org/10.1557/s43578-022-00547-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00547-9