Abstract

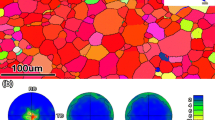

Tensile twinning plays an important role in the magnesium alloys. In this work, the microstructures and the twinning behaviors in a rolled AZ31 magnesium alloy have been investigated during strain path change using quasi in situ electron-backscattered diffraction method. The results show that detwinning can only occur in grains with certain orientations and is not prevalent in this case. Under compressive strain along the rolling direction, single twin variant with the highest Schmid factor value can be activated, while under re-compressive strain along the transverse direction, several more types of twin variants can be activated. The activation of \(\left\{ {10\bar{1}2} \right\} - \left\{ {10\bar{1}2} \right\}\) double twin has also been observed during strain path change. The double twin activation confirms that one twin variant cannot transmit through another twin variant, but forms an “apparent crossing” twin structure.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

M.K. Kulekci, Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 39(9–10), 851 (2008)

Z. Zeng, N. Stanford, C.H.J. Davies, J.-F. Nie, N. Birbilis, Magnesium extrusion alloys: a review of developments and prospects. Int. Mater. Rev. 64(1), 27 (2019)

H. Pan, Y. Ren, H. Fu, H. Zhao, W. Liqing, X. Meng, G. Qin, Recent developments in rare-earth free wrought magnesium alloys having high strength: a review. J. Alloys Compd. 663, 321 (2016)

Z. Wu, W.A. Curtin, The origins of high hardening and low ductility in magnesium. Nature 526(7571), 62 (2015)

C.D. Barrett, A. Imandoust, H. El Kadiri, The effect of rare earth element segregation on grain boundary energy and mobility in magnesium and ensuing texture weakening. Scr. Mater. 146, 46 (2018)

I. Basu, T. Al-Samman, Twin recrystallization mechanisms in magnesium-rare earth alloys. Acta Mater. 96, 111 (2015)

J. Bohlen, J. Wendt, M. Nienaber, K.U. Kainer, L. Stutz, D. Letzig, Calcium and zirconium as texture modifiers during rolling and annealing of magnesium–zinc alloys. Mater. Charact. 101, 144 (2015)

B. Zhang, Y. Wang, L. Geng, C. Lu, Effects of calcium on texture and mechanical properties of hot-extruded Mg–Zn–Ca alloys. Mater. Sci. Eng. A 539, 56 (2012)

D. Guan, W.M. Rainforth, J. Gao, J. Sharp, B. Wynne, L. Ma, Individual effect of recrystallisation nucleation sites on texture weakening in a magnesium alloy: part 1- double twins. Acta Mater. 135, 14 (2017)

D. Guan, W.M. Rainforth, L. Ma, B. Wynne, J. Gao, Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy. Acta Mater. 126, 132 (2017)

D. Song, T. Zhou, J. Tu, L. Shi, B. Song, L. Hu, M. Yang, Q. Chen, L. Lu, Improved stretch formability of AZ31 sheet via texture control by introducing a continuous bending channel into equal channel angular rolling. J. Mater. Process. Technol. 259, 380 (2018)

M.G. Jiang, C. Xu, H. Yan, G.H. Fan, T. Nakata, C.S. Lao, R.S. Chen, S. Kamado, E.H. Han, B.H. Lu, Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion. Acta Mater. 157, 53 (2018)

D. Guan, B. Wynne, J. Gao, Y. Huang, W.M. Rainforth, Basal slip mediated tension twin variant selection in magnesium WE43 alloy. Acta Mater. 170, 1 (2019)

H. El Kadiri, C.D. Barrett, J. Wang, C.N. Tomé, Why are 10 1 ¯ 2 twins profuse in magnesium? Acta Mater. 85, 354 (2015)

D. Hou, T. Liu, M. Shi, H. Wen, H. Zhao, Deformation mechanisms in a rolled magnesium alloy under tension along the rolling direction. Microsc. Microanal. 24(3), 207 (2018)

M.R. Barnett, M.D. Nave, A. Ghaderi, Yield point elongation due to twinning in a magnesium alloy. Acta Mater. 60(4), 1433 (2012)

Z. Ding, W. Liu, H. Sun, S. Li, D. Zhang, Y. Zhao, E.J. Lavernia, Y. Zhu, Origins and dissociation of pyramidal dislocations in magnesium and its alloys. Acta Mater. 146, 265 (2018)

B.-Y. Liu, F. Liu, N. Yang, X.-B. Zhai, L. Zhang, Y. Yang, B. Li, J. Li, E. Ma, J.-F. Nie, Z.-W. Shan, Large plasticity in magnesium mediated by pyramidal dislocations. Science 365(6448), 73 (2019)

Y. Bu, Z. Li, J. Liu, H. Wang, D. Raabe, W. Yang, Nonbasal slip systems enable a strong and ductile hexagonal-close-packed high-entropy phase. Phys. Rev. Lett. 122(7), 075502 (2019)

D. Hou, Y. Zhu, H. Wen, Roles of twinning and slipping in tensile anisotropy of rolled Mg–3Al–Zn alloy. Mater. Sci. Eng. A 823, 141748 (2021)

J.C. Stinville, E.R. Yao, P.G. Callahan, J. Shin, F. Wang, M.P. Echlin, T.M. Pollock, D.S. Gianola, Dislocation dynamics in a nickel-based superalloy via in-situ transmission scanning electron microscopy. Acta Mater. 168, 152 (2019)

S. Kondo, T. Mitsuma, N. Shibata, Y. Ikuhara, Direct observation of individual dislocation interaction processes with grain boundaries. Sci. Adv. 2(11), e1501926 (2016)

H. Fan, J.A. El-Awady, Towards resolving the anonymity of pyramidal slip in magnesium. Mater. Sci. Eng. A 644, 318 (2015)

H. Lim, J.D. Carroll, J.R. Michael, C.C. Battaile, S.R. Chen, J.M.D. Lane, Investigating active slip planes in tantalum under compressive load: crystal plasticity and slip trace analyses of single crystals. Acta Mater. 185, 1 (2020)

C.M. Cepeda-Jimenez, J.M. Molina-Aldareguia, M.T. Perez-Prado, Effect of grain size on slip activity in pure magnesium polycrystals. Acta Mater. 84, 443 (2015)

I. Basu, T. Al-Samman, Competitive twinning behavior in magnesium and its impact on recrystallization and texture formation. Mater. Sci. Eng. A 707, 232 (2017)

H. Fan, S. Aubry, A. Arsenlis, J.A. El-Awady, Orientation influence on grain size effects in ultrafine-grained magnesium. Scr. Mater. 97, 25 (2015)

D. Culbertson, Q. Yu, Y. Jiang, In situ observation of cross-grain twin pair formation in pure magnesium. Philos. Mag. Lett. 98(4), 139 (2018)

M.A. Lopez-Sanchez, A. Tommasi, F. Barou, R. Quey, Dislocation-driven recrystallization in AZ31B magnesium alloy imaged by quasi-in situ EBSD in annealing experiments. Mater. Charact. 165, 110382 (2020)

S.W. Lee, S.H. Park, Static recrystallization mechanism in cold-rolled magnesium alloy with off-basal texture based on quasi in situ EBSD observations. J. Alloys Compd. 844, 156185 (2020)

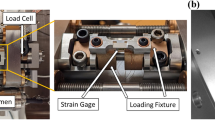

H.J. Yang, S.M. Yin, C.X. Huang, Z.F. Zhang, S.D. Wu, S.X. Li, Y.D. Liu, EBSD study on deformation twinning in AZ31 magnesium alloy during quasi-in-situ compression. Adv. Eng. Mater. 10(10), 955 (2008)

A. Ghaderi, M.R. Barnett, Sensitivity of deformation twinning to grain size in titanium and magnesium. Acta Mater. 59(20), 7824 (2011)

J. Wang, M.R.G. Ferdowsi, S.R. Kada, C.R. Hutchinson, M.R. Barnett, Influence of precipitation on yield elongation in Mg-Zn alloys. Scr. Mater. 160, 5 (2019)

G. Proust, C.N. Tomé, A. Jain, S.R. Agnew, Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy AZ31. Int. J. Plast 25(5), 861 (2009)

G. Liu, J. Zhang, G. Xi, R. Zuo, S. Liu, Designing Mg alloys with high ductility: reducing the strength discrepancies between soft deformation modes and hard deformation modes. Acta Mater. 141, 1 (2017)

Z.S. Basinski, M.S. Szczerba, M. Niewczas, J.D. Embury, S.J. Basinski, The transformation of slipdislocations during twinning ofcopper-aluminum alloy crystals. Rev. Metall. Paris 94(9), 1037 (1997)

F. Wang, C.D. Barrett, R.J. McCabe, H. El Kadiri, L. Capolungo, S.R. Agnew, Dislocation induced twin growth and formation of basal stacking faults in 10 1¯ 2 twins in pure Mg. Acta Mater. 165, 471 (2019)

D. Hou, T. Liu, H. Chen, D. Shi, C. Ran, F. Pan, Analysis of the microstructure and deformation mechanisms by compression along normal direction in a rolled AZ31 magnesium alloy. Mater. Sci. Eng. A 660, 102 (2016)

W.B. Hutchinson, M.R. Barnett, Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Scr. Mater. 63(7), 737 (2010)

G. Nayyeri, W.J. Poole, C.W. Sinclair, S. Zaefferer, Measurement of the critical resolved shear stress for basal slip in magnesium alloys using instrumented indentation. Scr. Mater. 156, 37 (2018)

S.R. Agnew, Ö. Duygulu, Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast 21(6), 1161 (2005)

M.R. Barnett, Twinning and the ductility of magnesium alloys. Mater. Sci. Eng. A 464(1–2), 1 (2007)

P. Chen, F. Wang, J. Ombogo, B. Li, Formation of 60° 〈 01 1 ̅ 0 〉 boundaries between 10 1 ̅ 2 twin variants in deformation of a magnesium alloy. Mater. Sci. Eng. A 739, 173 (2019)

P. Dobroň, F. Chmelík, S. Yi, K. Parfenenko, D. Letzig, J. Bohlen, Grain size effects on deformation twinning in an extruded magnesium alloy tested in compression. Scr. Mater. 65(5), 424 (2011)

C.M. Cepeda-Jiménez, J.M. Molina-Aldareguia, M.T. Pérez-Prado, Origin of the twinning to slip transition with grain size refinement, with decreasing strain rate and with increasing temperature in magnesium. Acta Mater. 88, 232 (2015)

S. Godet, L. Jiang, A. Luo, J. Jonas, Use of Schmid factors to select extension twin variants in extruded magnesium alloy tubes. Scr. Mater. 55(11), 1055 (2006)

S. H. Park, J. H. Lee, Y.-H. Huh, S.-G. Hong, Enhancing the effect of texture control using {1 0 –1 2} twins by retarding detwinning activity in rolled Mg–3Al–1Zn alloy. Scr. Mater. 4 (2013).

Q. Yu, J. Wang, Y. Jiang, R.J. McCabe, N. Li, C.N. Tomé, Twin–twin interactions in magnesium. Acta Mater. 77, 28 (2014)

F. Mokdad, D.L. Chen, D.Y. Li, Single and double twin nucleation, growth, and interaction in an extruded magnesium alloy. Mater. Des. 119, 376 (2017)

R. Xin, M. Wang, X. Huang, C. Guo, Q. Liu, Observation and Schmid factor analysis of multiple twins in a warm-rolled Mg–3Al–1Zn alloy. Mater. Sci. Eng. A 596, 41 (2014)

B. Clausen, C.N. Tomé, D.W. Brown, S.R. Agnew, Reorientation and stress relaxation due to twinning: modeling and experimental characterization for Mg. Acta Mater. 56(11), 2456 (2008)

N.C. Ferreri, Z. Feng, D.J. Savage, D.W. Brown, B. Clausen, T.A. Sisneros, M. Knezevic, In-situ high-energy X-ray diffraction and crystal plasticity modeling to predict the evolution of texture, twinning, lattice strains and strength during loading and reloading of beryllium. Int. J. Plast. 150, 103217 (2022)

Acknowledgments

This work was supported by the Office of China Postdoctoral Council under Award No. YJ20200248, the Beijing Municipal Natural Science Foundation (No. 2214072), and the Interdisciplinary Research Project for Young Teachers of USTB (Fundamental Research Funds for the Central Universities) (FRF-IDRY-20-034).

Funding

Funding was provided by Office of China Postdoctoral Council (YJ20200248), Beijing Municipal Natural Science Foundation (No. 2214072), Interdisciplinary Research Project for Young Teachers of USTB (FRF-IDRY-20-034).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationship that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Zhu, Y., Chen, X., Chen, K. et al. Quasi in situ observation of twinning evolution during strain path change in magnesium alloy. Journal of Materials Research 37, 1125–1132 (2022). https://doi.org/10.1557/s43578-022-00507-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00507-3