Abstract

The deformation mechanisms and mechanical properties of Cu/Fe multilayer during compression process are investigated via atomistic simulations and rationalized analysis. It is found that yield stress and strain of Kurdjumov–Sachs model are lower than that of Nishiyama–Wassermann model, and lattice dislocation nucleates from periodic arrangement structures on the interface. We present that preferred slip systems are dominated not only by Schmidt factors but also by intersection line orientations of slip system on the interface, as well as angles between activated slip system of Cu layer and slip system of Fe layer. During deformation process, extended full dislocation dominates deformation behavior of Cu layer, and perfect dislocation and twinning dominate deformation behavior of Fe layer. After deformation, tetrahedral structures and point defects form on Cu side of interface and inside Fe layer, respectively. We calculate evolution curves for number of dislocation segments and interface thickness to illuminate deformation behavior.

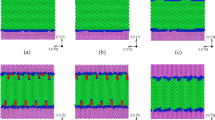

Graphic abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

J. Li, Y. Chen, S. Xue, H. Wang, X. Zhang, Comparison of size dependent strengthening mechanisms in Ag/Fe and Ag/Ni multilayers. Acta Mater. 114, 154 (2016)

M. Callisti, T. Polcar, Combined size and texture-dependent deformation and strengthening mechanisms in Zr/Nb nano-multilayers. Acta Mater. 124, 247 (2017)

Y.F. Zhang, R. Su, T.J. Niu, N.A. Richter, S. Xue, Q. Li, J. Ding, B. Yang, H. Wang, X. Zhang, Thermal stability and deformability of annealed nanotwinned Al/Ti multilayers . Scr. Mater. 186, 219 (2020)

S.J. Zheng, I.J. Beyerlein, J.S. Carpenter, K. Kang, J. Wang, W.Z. Han, N.A. Mara, High-strength and thermally stable bulk nanolayered composites due to twin-induced interfaces. Nat. Commun. 4(1), 1–8 (2013)

Q. Zhou, P. Huang, M.B. Liu, F. Wang, K.W. Xu, T.J. Lu, Grain and interface boundaries governed strengthening mechanisms in metallic multilayers. J. Alloy Compds. 698, 906 (2017)

X.F. Kong, I.J. Beyerlein, Z.R. Liu, B.N. Yao, D. Legut, T.C. Germann, R.F. Zhang, Stronger and more failure-resistant with three-dimensional serrated bimetal interfaces. Acta Mater. 166, 231 (2019)

N. Abdolrahim, H.M. Zbib, D.F. Bahr, Multiscale modeling and simulation of deformation in nanoscale metallic multilayer systems. Int. J. Plast. 52, 33 (2014)

R.F. Zhang, T.C. Germann, X.Y. Liu, J. Wang, I.J. Beyerlein, Layer size effect on the shock compression behavior of fcc–bcc nanolaminates. Acta Mater. 79, 74 (2014)

L. Lu, C. Huang, W.L. Pi, H.G. Xiang, F.S. Gao, T. Fu, X.H. Peng, Molecular dynamics simulation of effects of interface imperfections and modulation periods on Cu/Ta multilayers. Comput. Mater. Sci. 143, 63 (2018)

X. Tian, J.Z. Cui, M. Yang, K.P. Ma, M.Z. Xiang, Molecular dynamics simulations on shock response and spalling behaviors of semi-coherent 111 Cu-Al multilayers. Int. J. Mech. Sci. 172, 105414 (2020)

Y. Liu, Y. Chen, K.Y. Yu, H. Wang, J. Chen, X. Zhang, Stacking fault and partial dislocation dominated strengthening mechanisms in highly textured Cu/Co multilayers. Int. J. Plast. 49, 152 (2013)

W.Z. Han, E.K. Cerreta, N.A. Mara, I.J. Beyerlein, J.S. Carpenter, S.J. Zheng, C.P. Trujillo, P.O. Dickerson, A. Misra, Deformation and failure of shocked bulk Cu–Nb nanolaminates. Acta Mater. 63, 150 (2014)

W. Yang, G. Ayoub, I. Salehinia, B. Mansoor, H. Zbib, Multiaxial tension/compression asymmetry of Ti/TiN nano laminates: MD investigation. Acta Mater. 135, 348 (2017)

Y. Chen, S. Shao, X.Y. Liu, S.K. Yadav, N. Li, N. Mara, J. Wang, Misfit dislocation patterns of Mg-Nb interfaces. Acta Mater. 126, 552 (2017)

F.S. Gao, X.H. Peng, C. Huang, X. Yue, B. Yang, S. Sun, T. Fu, Modulation period dependent mechanical properties of Cu/Fe metallic multilayered films. AIP Adv. 8, 045208 (2018)

Y. Liu, D. Bufford, H. Wang, C. Sun, X. Zhang, Mechanical properties of highly textured Cu/Ni multilayers. Acta Mater. 59(5), 1924 (2011)

S. Shao, J. Wang, I.J. Beyerlein, A. Misra, Glide dislocation nucleation from dislocation nodes at semi-coherent 1 1 1 Cu–Ni interfaces. Acta Mater. 98, 206 (2015)

S. Shao, F. Akasheh, J. Wang, Y. Liu, Alternative misfit dislocations pattern in semi-coherent FCC 100 interfaces. Acta Mater. 144, 177 (2018)

D.L. Zheng, S.D. Chen, A.K. Soh, Y. Ma, Molecular dynamics simulations of glide dislocations induced by misfit dislocations at the Ni/Al interface. Comput. Mater. Sci. 48(3), 551 (2010)

H.G. Xiang, H.T. Li, T. Fu, W.B. Zhu, C. Huang, B. Yang, X.H. Peng, Shock-induced stacking fault pyramids in Ni/Al multilayers. Appl. Surf. Sci. 427, 219 (2018)

C. Lv, J. Yang, X.P. Zhang, Y. Cai, X.Y. Liu, G.J. Wang, S.-N. Luo, Interfacial effect on deformation and failure of Al/Cu nanolaminates under shear loading. J. Phys. D 51(33), 335301 (2018)

I. Salehinia, J. Wang, D.F. Bahr, H.M. Zbib, Molecular dynamics simulations of plastic deformation in Nb/NbC multilayers . Int. J. Plast. 59, 119 (2014)

D. Bhattacharyya, N.A. Mara, R.G. Hoagland, A. Misra, Nanoindentation and microstructural studies of Al/TiN multilayers with unequal volume fractions. Scr. Mater. 58(11), 981 (2008)

S. Zheng, J.S. Carpenter, R.J. McCabe, I.J. Beyerlein, N.A. Mara, Engineering interface structures and thermal stabilities via SPD processing in bulk nanostructured metals. Sci. Rep. 4(1), 1–6 (2014)

J. Wang, R.F. Zhang, C.Z. Zhou, I.J. Beyerlein, A. Misra, Interface dislocation patterns and dislocation nucleation in face-centered-cubic and body-centered-cubic bicrystal interfaces . Int. J. Plast. 53, 40 (2014)

R.F. Zhang, J. Wang, I.J. Beyerlein, A. Misra, T.C. Germann, Atomic-scale study of nucleation of dislocations from fcc-bcc interfaces. Acta Mater. 60, 2855 (2012)

J.T. Avallone, T.J. Nizolek, B.B. Bales, T.M. Pollock, Creep resistance of bulk copper–niobium composites: an inverse effect of multilayer length scale. Acta Mater. 176, 189 (2019)

J. Chen, S.N. Mathaudhu, N. Thadhani, A.M. Dongare, Correlations between dislocation density evolution and spall strengths of Cu/Ta multilayered systems at the atomic scales: the role of spacing of KS interfaces. Materialia 5, 100192 (2019)

Q. Guo, J.R. Greer, Compressive properties of interface-containing Cu–Fe nano-pillars. Scr. Mater. 66(5), 272–275 (2012)

Y. Chen, Y. Liu, C. Sun, K.Y. Yu, M. Song, H. Wang, X. Zhang, Microstructure and strengthening mechanisms in Cu/Fe multilayers. Acta Mater. 60(18), 6312 (2012)

J.T. Wang, C.H. Yang, P.D. Hodgson, Extrinsic size effect in microcompression of polycrystalline Cu/Fe multilayers. Scr. Mater. 69(8), 626 (2013)

Y.H. Yang, D.Z. Wang, J. Lin, D.F. Khan, G.Y. Lin, J.D. Ma, Evolution of structure and fabrication of Cu/Fe multilayered composites by a repeated diffusion-rolling procedure. Mater. Des. 85, 635 (2015)

L.F. Zhang, R. Gao, B.L. Zhao, M. Sun, K. Jing, X.P. Wang, T. Hao, Z.M. Xie, R. Liu, Q.F. Fang, C.S. Liu, Effects of annealing temperature and layer thickness on hardening behavior in cross accumulative roll bonded Cu/Fe nanolamellar composite. J. Alloy Compds. 827, 154312 (2020)

N. Koga, S. Tomono, O. Umezawa, Low-temperature tensile properties of Cu-Fe laminated sheets with various number of layers. Mater. Sci. Eng. A 811, 141066 (2021)

H. Zhang, K.X. Jiao, J.L. Zhang, J. Liu, Experimental and numerical investigations of interface characteristics of copper/steel composite prepared by explosive welding. Mater. Des. 154, 140 (2018)

J. Zou, D. Lu, Q. Fu, K. Liu, J. Jiang, Microstructure and properties of Cu–Fe deformation processed in-situ composite. Vacuum 167, 54 (2019)

S.V. Gladkovsky, S.V. Kuteneva, S.N. Sergeev, Microstructure and mechanical properties of sandwich copper/steel composites produced by explosive welding. Mater. Charact. 154, 294 (2019)

F.X. Yin, Y.Z. Zhao, S.Y. Yu, W.W. Pang, Molecular dynamics studies on the interface evolution characteristics and deformation mechanisms of Cu/Al multilayers during compression process. J. Appl. Phys. 125(2), 025112 (2019)

J. Wang, C. Yang, P.D. Hodgson, Mechanical behavior of nano-crystalline metallic thin films and multilayers under microcompression. Metall. Mater. Trans. A. 46(3), 1405 (2015)

N. Li, J. Wang, A. Misra, J.Y. Huang, Direct observations of confined layer slip in Cu/Nb multilayers. Microsc. Microanal. 18(5), 1155 (2012)

G. Bonny, R.C. Pasianot, N. Castin, L. Malerba, Ternary Fe–Cu–Ni many-body potential to model reactor pressure vessel steels: first validation by simulated thermal annealing. Philos. Mag. 89(34–36), 3531 (2009)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Model. Simul. Mater. Sci. Eng. 18(1), 015012 (2010)

D. Faken, H. Jónsson, Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 2, 279 (1994)

A. Stukowski, Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 20(4), 045021 (2012)

Acknowledgments

This work is financially supported by the National Natural Science Foundation of China (Grant No. 11747015).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Feng, X., Lin, Z., Xin, K. et al. The deformation mechanisms and mechanical properties of Cu/Fe multilayer during compression process. Journal of Materials Research 36, 3203–3213 (2021). https://doi.org/10.1557/s43578-021-00333-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00333-z