Abstract

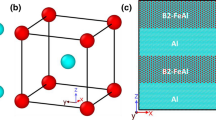

In this work, we study the deformation behavior in amorphous/crystalline metallic composites (A/C-MCs) through nanoindentation experiments and molecular dynamic (MD) simulations. The atomic deformation processes in both crystalline (C-) and amorphous (A-) phases near the amorphous-crystalline interface (ACI) are investigated and correlated with the material’s overall constitutive behavior at the microscale. Our major findings are (i) the ACIs enable a co-deformation of the A- and C-phases through “stiffening” the soft phases but “softening” the stiff phases in A/C-MCs through different micro-mechanisms; (ii) there exists an ACI-induced transition zone with a thickness of ~ 10 nm; (iii) the strong coupling between shear transformation zones (STZs) and dislocations can be quantified through carefully designed indentation experiments and simulations; and (iv) the nanoscale MD-simulation-predicted mechanisms can be mapped to the “pop-in” or “excursion” events on the force–indentation depth curves extracted from microscale experiments, although there is a length-scale gap in between.

Graphic abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

M. Chen, Mechanical behavior of metallic glasses: microscopic understanding of strength and ductility. Annu. Rev. Mater. Res. 38, 445–469 (2008)

J.P. Chu, J.S.C. Jang, J.C. Huang, H.S. Chou, Y. Yang, J.C. Ye et al., Thin film metallic glasses: unique properties and potential applications. Thin Solid Films 520(16), 5097–5122 (2012)

M. Chen, A brief overview of bulk metallic glasses. NPG Asia Mater. 3(9), 82–90 (2011)

J. Schroers, The superplastic forming of bulk metallic glasses. JOM 57(5), 35–39 (2005)

A. Donohue, F. Spaepen, R.G. Hoagland, A. Misra, Suppression of the shear band instability during plastic flow of nanometer-scale confined metallic glasses. Appl. Phys. Lett. 91(24), (2007)

A. Antoniou, A. Bastawros, B. Biner, Experimental observations of deformation behavior of bulk metallic glasses during wedge-like cylindrical indentation. J. Mater. Res. 22, 514–524 (2007)

M.J. Kramer, D.J. Sordelet, A.F. Bastawros, X. Tan, S.B. Biner, Absence of crystallization during cylindrical indentation of a Zr-based metallic glass. J. Non Cryst. Solids 351, 2159–2165 (2005)

A. Antoniou, A.F. Bastawros, C.C.H. Lo, S.B. Biner, Deformation behavior of a zirconium based metallic glass during cylindrical indentation: in situ observations. Mater. Sci. Eng., A 394, 96–102 (2005)

A. Antoniou, S.B. Biner, A.F. Bastawros, Experimental observation of cylindrical indentation of a metallic glass. Materials Research Society Symposium Proceedings, 903, 0903-Z12-0 (2005)

A.A. Voevodin, J.S. Zabinski, Load-adaptive crystalline–amorphous nanocomposites. J. Mater. Sci. 33(2), 319–327 (1998)

Y. Wang, J. Li, A.V. Hamza, T.W. Barbee, Ductile crystalline–amorphous nanolaminates. Proc. Natl. Acad. Sci. 104(27), 11155–11160 (2007)

A. Khalajhedayati, Z. Pan, T.J. Rupert, Manipulating the interfacial structure of nanomaterials to achieve a unique combination of strength and ductility. Nat. Commun. 7(1), 1–8 (2016)

D. Zhao, S. Wang, B. Zhu, L. Li, H. Zhao, Anisotropic deformation behaviors of amorphous-crystalline nanolaminates investigated via molecular dynamics simulations. J. Alloys Compd. 787, 649–657 (2019)

T. Phan, J. Rigelesaiyin, Y. Chen, A. Bastawros, L. Xiong, Metallic glass instability induced by the continuous dislocation absorption at an amorphous/crystalline interface. Acta Mater. 189, 10–24 (2020)

M.C. Liu, J.C. Huang, Y.T. Fong, S.P. Ju, X.H. Du, H.J. Pei, T.G. Nieh, Assessing the interfacial strength of an amorphous–crystalline interface. Acta Mater. 61(9), 3304–3313 (2013)

L. Zhao, K.C. Chan, S.H. Chen, Atomistic deformation mechanisms of amorphous/polycrystalline metallic nanolaminates. Intermetallics 95, 102–109 (2018)

S.D. Feng, L. Li, K.C. Chan, L. Qi, L. Zhao, L.M. Wang, R.P. Liu, Control of shear band dynamics in Cu50Zr50 metallic glass by introducing amorphous-crystalline interfaces. J. Alloy. Compd. 770, 896–905 (2019)

W. Guo, E. Jägle, J. Yao, V. Maier, S. Korte-Kerzel, J.M. Schneider, D. Raabe, Intrinsic and extrinsic size effects in the deformation of amorphous CuZr/nanocrystalline Cu nanolaminates. Acta Mater. 80, 94–106 (2014)

B. Arman, C. Brandl, S.N. Luo, T.C. Germann, A. Misra, T. Çağin, Plasticity in Cu (111)/Cu46Zr54 glass nanolaminates under uniaxial compression. J. Appl. Phys. 110(4), 043539 (2011)

C.A. Schuh, T.C. Hufnagel, U. Ramamurty, Mechanical behavior of amorphous alloys. Acta Mater. 55(12), 4067–4109 (2007)

Y.Q. Wang, J.Y. Zhang, X.Q. Liang, K. Wu, G. Liu, J. Sun, Size-and constituent-dependent deformation mechanisms and strain rate sensitivity in nanolaminated crystalline Cu/amorphous Cu–Zr films. Acta Mater. 95, 132–144 (2015)

J.Y. Zhang, G. Liu, S.Y. Lei, J.J. Niu, J. Sun, Transition from homogeneous-like to shear-band deformation in nanolayered crystalline Cu/amorphous Cu–Zr micropillars: intrinsic vs. extrinsic size effect. Acta Mater. 60(20), 7183–7196 (2012)

J.Y. Zhang, Y.Q. Wang, X.Q. Liang, F.L. Zeng, G. Liu, J. Sun, Size-dependent He-irradiated tolerance and plastic deformation of crystalline/amorphous Cu/Cu–Zr nanolaminates. Acta Mater. 92, 140–151 (2015)

J.Y. Zhang, Y. Liu, J. Chen, Y. Chen, G. Liu, X. Zhang, J. Sun, Mechanical properties of crystalline Cu/Zr and crystal–amorphous Cu/Cu–Zr multilayers. Mater. Sci. Eng., A 552, 392–398 (2012)

W.R. Jian, L. Wang, X.H. Yao, S.N. Luo, Tensile and nanoindentation deformation of amorphous/crystalline nanolaminates: effects of layer thickness and interface type. Comput. Mater. Sci. 154, 225–233 (2018)

W.J. Lee, Y.C. Lo, A. Yang, K. Chen, N.Y. Chen, Thickness effect of nanocrystalline layer on the deformation mechanism of amorphous/crystalline multilayered structure. CMES 120(2), 293–304 (2019)

C. Brandl, T.C. Germann, A. Misra, Structure and shear deformation of metallic crystalline–amorphous interfaces. Acta Mater. 61(10), 3600–3611 (2013)

H. Zhou, S. Qu, W. Yang, An atomistic investigation of structural evolution in metallic glass matrix composites. Int. J. Plast 44, 147–160 (2013)

J.Y. Zhang, G. Liu, J. Sun, Crystallization-aided extraordinary plastic deformation in nanolayered crystalline Cu/amorphous Cu-Zr micropillars. Sci. Rep. 3(1), 1–6 (2013)

F. Abdeljaward, M. Haataja, Continuum modeling of bulk metallic glasses and composites. Phys. Rev. Lett. 105, (2010)

G.P. Zheng, Application of phase-field modeling to deformation of metallic glasses. Curr. Opin. Solid State Mater. Sci. 15, 116–124 (2011)

M.H. Lee, D.H. Bae, D.H. Kim, D.J. Sordelet, Synthesis of Ni-based bulk metallic glass matrix composites containing ductile brass phase by warm extrusion of gas atomized powders. J. Mater. Res. 18(9), 2101–2108 (2003)

K. Durst, M. Göken, G.M. Pharr, Indentation size effect in spherical and pyramidal indentations. J. Phys. D Appl. Phys. 41(7), (2008)

X.W. Zhou, R.A. Johnson, H.N.G. Wadley, Phys. Rev. B 69, 144113 (2004)

M.I. Mendelev, M.J. Kramer, R.T. Ott, D.J. Sordelet, D. Yagodin, P. Popel, Development of suitable interatomic potentials for simulation of liquid and amorphous Cu–Zr alloys. Philos. Mag. 89(11), 967–987 (2009)

M.I. Mendelev, D.J. Sordelet, M.J. Kramer, Using atomistic computer simulations to analyze x-ray diffraction data from metallic glasses. J. Appl. Phys. 102(4), 043501 (2007)

M.I. Mendelev, M.J. Kramer, R.T. Ott, D.J. Sordelet, Molecular dynamics simulation of diffusion in supercooled Cu–Zr alloys. Philos. Mag. 89(2), 109–126 (2009)

C. Yang, C.T. Lo, A.F. Bastawros, B. Narasimhan, Measurements of diffusion thickness at polymer interfaces by nanoindentation: a numerically calibrated experimental approach. J. Mater. Res. 24(3), 985–992 (2009)

D. Xu, B. Lohwongwatana, G. Duan, W.L. Johnson, C. Garland, Bulk metallic glass formation in binary Cu-rich alloy series–Cu100 − xZrx (x = 34, 36, 38.2, 40 at.%) and mechanical properties of bulk Cu64Zr36 glass. Acta Mater. 52(9), 2621–2624 (2004)

Q. Guo, L. Zhang, A.S. Zeiger, Y. Li, K.J. Van Vliet, C.V. Thompson, Compositional dependence of Young’s moduli for amorphous Cu–Zr films measured using combinatorial deposition on microscale cantilever arrays. Scr. Mater. 64(1), 41–44 (2011)

J.C. Lee, K.W. Park, K.H. Kim, E. Fleury, B.J. Lee, M. Wakeda, Y. Shibutani, Origin of the plasticity in bulk amorphous alloys. J. Mater. Res. 22(11), 3087–3097 (2007)

M.I. Mendelev, R.T. Ott, M. Heggen, M. Feuerebacher, M.J. Kramer, D.J. Sordelet, Deformation behavior of an amorphous Cu 64.5 Zr 35.5 alloy: a combined computer simulation and experimental study. J. Appl. Phys. 104(12), 123532 (2008)

C. Deng, C.A. Schuh, Atomistic mechanisms of cyclic hardening in metallic glass. Appl. Phys. Lett. 100(25), 251909 (2012)

C. Qiu, P. Zhu, F. Fang, D. Yuan, X. Shen, Study of nanoindentation behavior of amorphous alloy using molecular dynamics. Appl. Surf. Sci. 305, 101–110 (2014)

T. Tsuru, Y. Shibutani, Anisotropic effects in elastic and incipient plastic deformation under (001), (110), and (111) nanoindentation of Al and Cu. Phys. Rev. B 75(3), 035415 (2007)

H. Liang, C.H. Woo, H. Huang, A.H.W. Ngan, T.X. Yu, Crystalline plasticity on copper (001), (110), and (111) surfaces during nanoindentation. Comput. Model. Eng. Sci. 6, 105–114 (2004)

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, 1985)

A. Gouldstone, H.J. Koh, K.Y. Zeng, A.E. Giannakopoulos, S. Suresh, Discrete and continuous deformation during nanoindentation of thin films. Acta Mater. 48(9), 2277–2295 (2000)

D.F. Bahr, D.E. Wilson, D.A. Crowson, Energy considerations regarding yield points during indentation. J. Mater. Res. 14(6), 2269–2275 (1999)

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564–1583 (1992)

J.G. Swadener, E.P. George, G.M. Pharr, The correlation of the indentation size effect measured with indenters of various shapes. J. Mech. Phys. Solids 50(4), 681–694 (2002)

G.Z. Voyiadjis, M. Yaghoobi, Large scale atomistic simulation of size effects during nanoindentation: dislocation length and hardness. Mater. Sci. Eng., A 634, 20–31 (2015)

G. I. Taylor, The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proceedings of the Royal Society of London. Series A, Containing Papers of a Mathematical and Physical Character 145(855), 362–387 (1934)

W.D. Nix, H. Gao, Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46(3), 411–425 (1998)

D.H. Bae, M.H. Lee, D.H. Kim, D.J. Sordelet, Plasticity in Ni59Zr20Ti16Si2Sn3 metallic glass matrix composites containing brass fibers synthesized by warm extrusion of powders. Appl. Phys. Lett. 83(12), 2312–2314 (2003)

H. Wang, A.F. Bastawros, S.B. Biner, Experimental observation of the failure mechanisms in a bulk metallic glass composite. Mater. Res. Soc. Symp. Proc. 1048, 501 (2007)

L. Xiong, Y. Chen, Multiscale modeling and simulation of single-crystal MgO through an atomistic field theory. Int. J. Solids Struct. 46(6), 1448–1455 (2009)

L. Xiong, A concurrent atomistic-continuum methodology and its applications, PhD Dissertation, Gainesville: University of Florida, (2011)

L. Xiong, Q. Deng, G. Tucker, D.L. McDowell, Y. Chen, A concurrent scheme for passing dislocations from atomistic to continuum domains. Acta Mater. 60(3), 899–913 (2012)

S. Xu, L. Xiong, Y. Chen, D.L. McDowell, Sequential slip transfer of mixed-character dislocations across Ʃ3 coherent twin boundary in fcc metals: a concurrent atomistic-continuum study. NPJ Comput. Mater. 2(1), 1–9 (2016)

S. Xu, L. Xiong, Q. Deng, D.L. McDowell, Mesh refinement scheme for the concurrent atomistic-continuum method. Int. J. Solids Struct. 90, 144–152 (2016)

S. Xu, L. Xiong, Y. Chen, D.L. McDowell, Validation of the concurrent atomistic-continuum method on screw dislocation/stacking fault interactions. Crystals 7(5), 120 (2017)

X. Chen, W. Li, L. Xiong, Y. Li, S. Yang, Z. Zheng, D.L. McDowell, Y. Chen, Ballistic-diffusive phonon heat transport across grain boundaries. Acta Mater. 136, 355–365 (2017)

X. Chen, L. Xiong, D.L. McDowell, Y. Chen, Effects of phonons on mobility of dislocations and dislocation arrays. Scr. Mater. 137, 22–26 (2017)

X. Chen, A. Diaz, L. Xiong, D.L. McDowell, Y. Chen, Passing waves from atomistic to continuum. J. Comput. Phys. 354, 393–402 (2018)

S. Xu, T.G. Payne, H. Chen, Y. Liu, L. Xiong, Y. Chen, D.L. McDowell, PyCAC: the concurrent atomistic-continuum simulation environment. J. Mater. Res. 33(7), 857 (2018)

H. Chen, S. Xu, W. Li, R. Ji, T. Phan, L. Xiong, A spatial decomposition parallel algorithm for a concurrent atomistic-continuum simulation and its preliminary applications. Comput. Mater. Sci. 144, 1–10 (2018)

Acknowledgments

We acknowledge the support of the US National Science Foundation (NSF) with an award number of DMR-1807545 and the Extreme Science and Engineering Discovery Environment (XSEDE-TG-MSS170003 and XSEDE-TG-MSS190008). TP and LX also acknowledge the support of NSF under an award number of CMMI-1930093.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Liming Xiong was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Abdelmawla, A., Phan, T., Xiong, L. et al. A combined experimental and computational analysis on how material interface mediates plastic flow in amorphous/crystalline composites. Journal of Materials Research 36, 2816–2829 (2021). https://doi.org/10.1557/s43578-021-00269-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00269-4