Abstract

High-frequency induction heating is frequently used to consolidate solid pieces of refractory ceramics. However, this valuable technique has not been deeply evaluated for sample preparation in light metal-based systems as an economical and feasible alternative for rapid sintering routes such as spark plasma sintering. This work deals with the potential use of induction heating to produce highly densified samples with refined microstructure, enhanced mechanical properties, and lower oxygen contamination. Here we demonstrate that induction-sintering can increase the hardness and yield strength in 70 and 80% respectively, compared to a commercial hardened alloy (AA-1350-H19). Theoretical calculations demonstrate that this behavior can be attributed to two main reinforcement mechanisms: dislocations obstruction and grain refinement. The increased mechanical response can be imputed to the effective sub-micron microstructure retention due to its shorter processing time and lower temperature compared to the conventional sintering process.

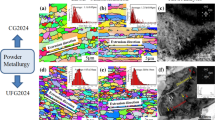

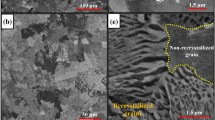

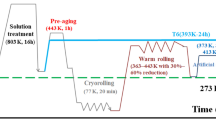

Graphic abstract

Similar content being viewed by others

References

R.B. Kalombo, J.M.G. Martínez, J.L.A. Ferreira, C.R.M. Da Silva, J.A. Araújo, Comparative fatigue resistance of overhead conductors made of aluminium and aluminium alloy: tests and analysis. Procedia Eng. 133, 223–232 (2015). https://doi.org/10.1016/j.proeng.2015.12.662

L.R. Zeng, Z.M. Song, X.M. Wu, C.H. Li, G.P. Zhang, Fatigue cracking behavior of 6063 aluminum alloy for fitting clamps of overhead conductor lines. Mater. Des. 88, 478–484 (2015). https://doi.org/10.1016/j.matdes.2015.09.021

I.J. Shon, K. Il Na, C.Y. Suh, S.W. Cho, S.H. Oh, W. Kim, Rapid consolidation of nanocrystalline Ti3Al-Al2O3 composites from mechanically synthesized powders by high frequency induction heated sintering. Met. Mater. Int. 17, 737–741 (2011). https://doi.org/10.1007/s12540-011-1007-1

E. Ghasali, M. Alizadeh, T. Ebadzadeh, A.H. Pakseresht, A. Rahbari, Investigation on microstructural and mechanical properties of B4C-aluminum matrix composites prepared by microwave sintering. J. Mater. Res. Technol. 4, 411–415 (2015). https://doi.org/10.1016/j.jmrt.2015.02.005

L.A. Yolshina, R.V. Muradymov, I.V. Korsun, G.A. Yakovlev, S.V. Smirnov, Novel aluminum-graphene and aluminum-graphite metallic composite materials: synthesis and properties. J. Alloys Compd. 663, 449–459 (2016). https://doi.org/10.1016/j.jallcom.2015.12.084

S. Karabay, Modification of AA-6201 alloy for manufacturing of high conductivity and extra high conductivity wires with property of high tensile stress after artificial aging heat treatment for all-aluminium alloy conductors. Mater. Des. 27, 821–832 (2006). https://doi.org/10.1016/j.matdes.2005.06.005

Z. Wang, H. Li, F. Miao, B. Fang, R. Song, Z. Zheng, Improving the strength and ductility of Al-Mg-Si-Cu alloys by a novel thermo-mechanical treatment. Mater. Sci. Eng., A 607, 313–317 (2014). https://doi.org/10.1016/j.msea.2014.04.009

B. Liu, X. Zhou, T. Hashimoto, X. Zhang, J. Wang, Machining introduced microstructure modification in aluminium alloys. J. Alloys Compd. 757, 233–238 (2018). https://doi.org/10.1016/j.jallcom.2018.05.082

D.J. Lloyd, I. Jin, Melt processed aluminum matrix particle reinforced composites. Compr. Compos. Mater. (2000). https://doi.org/10.1016/b0-08-042993-9/00020-6

Y.B. Yuan, Z.W. Wang, R.X. Zheng, X.N. Hao, K. Ameyama, C.L. Ma, Effect of mechanical alloying and sintering process on microstructure and mechanical properties of Al-Ni-Y-Co-La alloy. Trans. Nonferrous Met. Soc. China 24, 2251–2257 (2014). https://doi.org/10.1016/S1003-6326(14)63341-0

I. Marek, D. Vojtěch, A. Michalcová, T.F. Kubatík, High-strength bulk nano-crystalline silver prepared by selective leaching combined with spark plasma sintering. Mater. Sci. Eng., A 627, 326–332 (2015). https://doi.org/10.1016/j.msea.2015.01.014

C. Suryanarayana, Structure and properties of nanocrystalline materials. Bull. Mater. Sci. 17, 307–346 (1994)

I.J. Shon, S.L. Du, I.Y. Ko, T.W. Kim, J.M. Doh, J.K. Yoon, S.W. Park, Mechanical synthesis and rapid consolidation of a nanocrystalline 5.33Fe0.37Cr0.16Al0.4Si0.07-Al2O3 composite by high-frequency induction heating. Ceram. Int. 37, 1353–1357 (2011). https://doi.org/10.1016/j.ceramint.2010.12.008

N.R. Park, I.Y. Ko, J.M. Doh, W.Y. Kong, J.K. Yoon, I.J. Shon, Rapid consolidation of nanocrystalline 3Ni-Al2O3 composite from mechanically synthesized powders by high frequency induction heated sintering. Mater. Charact. 61, 277–282 (2010). https://doi.org/10.1016/j.matchar.2009.12.001

S. Jana, R.S. Mishra, J.A. Baumann, G.J. Grant, Effect of friction stir processing on microstructure and tensile properties of an investment cast Al-7Si-0.6 Mg alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 41, 2507–2521 (2010). https://doi.org/10.1007/s11661-010-0324-1

B. Gwalani, M. Olszta, S. Varma, L. Li, A. Soulami, E. Kautz, S. Pathak, A. Rohatgi, P.V. Sushko, S. Mathaudhu, C.A. Powell, A. Devaraj, Extreme shear-deformation-induced modification of defect structures and hierarchical microstructure in an Al–Si alloy. Commun. Mater. 1, 1–7 (2020). https://doi.org/10.1038/s43246-020-00087-x

C. Suryanarayana, I.-S. An, Mechanical alloying and milling. J. Korean Powder Metall. Inst. 13, 371–372 (2006). https://doi.org/10.4150/KPMI.2006.13.5.371

N.R. Park, D.M. Lee, I.Y. Ko, J.K. Yoon, I.J. Shon, Rapid consolidation of nanocrystalline Al2O3 reinforced Ni-Fe composite from mechanically alloyed powders by high frequency induction heated sintering. Ceram. Int. 35, 3147–3151 (2009). https://doi.org/10.1016/j.ceramint.2009.05.006

G.S. Upadhyaya, Some issues in sintering science and technology. Mater. Chem. Phys. 67, 1–5 (2001). https://doi.org/10.1016/S0254-0584(00)00411-9

K. Do Woo, B.R. Kim, E.P. Kwon, D.S. Kang, I.J. Shon, Properties and rapid consolidation of nanostructured TiC-based hard materials with various binders by a high-frequency induction heated sintering. Ceram. Int. 36, 351–355 (2010). https://doi.org/10.1016/j.ceramint.2009.09.005

I.J. Shon, I.K. Jeong, I.Y. Ko, J.M. Doh, K. Do Woo, Sintering behavior and mechanical properties of WC-10Co, WC-10Ni and WC-10Fe hard materials produced by high-frequency induction heated sintering. Ceram. Int. 35, 339–344 (2009). https://doi.org/10.1016/j.ceramint.2007.11.003

H.C. Kim, I.J. Shon, J.K. Yoon, J.M. Doh, Z.A. Munir, Rapid sintering of ultrafine WC-Ni cermets. Int. J. Refract. Met. Hard Mater. 24, 427–431 (2006). https://doi.org/10.1016/j.ijrmhm.2005.07.002

H.-C. Kim, D.-K. Kim, K.-D. Woo, I.-Y. Ko, I.-J. Shon, Consolidation of binderless WC–TiC by high frequency induction heating sintering. Int. J. Refract. Metals Hard Mater. 26, 48–54 (2008)

I.J. Shon, H.S. Oh, J.W. Lim, H. Kwon, Mechanical properties and consolidation of binderless nanostructured (Ti, Cr)C from mechanochemically-synthesized powder by high-frequency induction heating sintering. Ceram. Int. 39, 9721–9726 (2013). https://doi.org/10.1016/j.ceramint.2013.04.053

C. Suryanarayana, Mechanical alloying and milling. Prog. Mater Sci. 46, 1–184 (2001)

M. Mansoor, M. Shahid, Carbon nanotube-reinforced aluminum composite produced by induction melting. J. Appl. Res. Technol. 14, 215–224 (2016). https://doi.org/10.1016/j.jart.2016.05.002

A. Khorsand Zak, W.H. Abd. Majid, M.E. Abrishami, R. Yousefi, X-ray analysis of ZnO nanoparticles by Williamson-Hall and size-strain plot methods. Solid State Sci. 13, 251–256 (2011). https://doi.org/10.1016/j.solidstatesciences.2010.11.024

J.Y. Yoo, I.J. Shon, B.H. Choi, K.T. Lee, Fabrication and characterization of a Ni-YSZ anode support using high-frequency induction heated sintering (HFIHS). Ceram. Int. 37, 2569–2574 (2011). https://doi.org/10.1016/j.ceramint.2011.04.002

I.J. Shon, I.Y. Ko, H.S. Kang, K.T. Hong, J.M. Doh, J.K. Yoon, Properties and rapid consolidation of nanostructured Al2O3-Al2SiO5 composites by high frequency induction heated sintering. Ceram. Int. 37, 2159–2164 (2011). https://doi.org/10.1016/j.ceramint.2011.03.060

I.J. Shon, I.Y. Ko, S.M. Chae, K. Il Na, Rapid consolidation of nanostructured TaSi2 from mechanochemically synthesized powder by high frequency induction heated sintering. Ceram. Int. 37, 679–682 (2011). https://doi.org/10.1016/j.ceramint.2010.09.054

I.J. Shon, S.H. Jo, J.M. Doh, J.K. Yoon, B.J. Park, Mechanical synthesis and rapid consolidation of nanostructured FeAl-Al2O3 composites by high-frequency induction heated sintering. Ceram. Int. 38, 6035–6039 (2012). https://doi.org/10.1016/j.ceramint.2012.03.073

S.J. Park, N.H. Heung, H.O. Kyu, N.L. Dong, Model for compaction of metal powders. Int. J. Mech. Sci. 41, 121–141 (1999). https://doi.org/10.1016/S0020-7403(98)00022-8

Höganäs AB, Höganäs (2013) Handbook for Sintered Components Power of Powder ® Production of Sintered Components 2. www.hoganas.com/pmc

A.S. Jabur, Effect of powder metallurgy conditions on the properties of porous bronze. Powder Technol. 237, 477–483 (2013). https://doi.org/10.1016/j.powtec.2012.12.027

M. Zhou, S. Huang, J. Hu, Y. Lei, F. Zou, S. Yan, M. Yang, Experiment and finite element analysis of compaction densification mechanism of Ag-Cu-Sn-In mixed metal powder. Powder Technol. 313, 68–81 (2017). https://doi.org/10.1016/j.powtec.2017.03.015

B. Henriques, D. Soares, J.C. Teixeira, F.S. Silva, Effect of hot pressing variables on the microstructure, relative density and hardness of sterling silver (Ag-Cu alloy) powder compacts. Mater. Res. 17, 664–671 (2014). https://doi.org/10.1590/S1516-14392014005000022

F.A. Mirza, D.L. Chen, A unified model for the prediction of yield strength in particulate-reinforced metal matrix nanocomposites. Materials 8, 5138–5153 (2015). https://doi.org/10.3390/ma8085138

W.D. Wong-Ángel, L. Téllez-Jurado, E. Chavira-Martínez, J.F. Chávez-Alcalá, E. Rocha-Rangel, Effect of carbon on the density, microstructure and hardness of alloys formed by mechanical alloying. Mater. Des. 60, 605–611 (2014). https://doi.org/10.1016/j.matdes.2014.04.039

A. Güral, S. Tekeli, Microstructural characterization of intercritically annealed low alloy PM steels. Mater. Des. 28, 1224–1230 (2007). https://doi.org/10.1016/j.matdes.2006.01.007

N.S. Anas, M. Ramakrishna, R.K. Dash, T.N. Rao, R. Vijay, Influence of process control agents on microstructure and mechanical properties of Al alloy produced by mechanical alloying. Mater. Sci. Eng., A 751, 171–182 (2019)

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 62, 141–155 (2014). https://doi.org/10.1016/j.actamat.2013.09.042

T. Shanmugasundaram, M. Heilmaier, B.S. Murty, V.S. Sarma, On the Hall-Petch relationship in a nanostructured Al-Cu alloy. Mater. Sci. Eng., A 527, 7821–7825 (2010). https://doi.org/10.1016/j.msea.2010.08.070

I. Estrada-Guel, J.L. Cardoso, C. Careño-Gallardo, J.I. Barajas-Villaruel, M. Miki-Yoshida, J.M. Herrera-Ramírez, R. Martínez-Sánchez, Mechanical study on Al-based composites synthesized by mechanical milling and hot extrusion (Trans Tech Publications Ltd., Zurich, 2011). https://doi.org/10.4028/www.scientific.net/MSF.691.37

J.M. Mendoza-Duarte, I. Estrada-Guel, C. Carreño-Gallardo, R. Martínez-Sánchez, Study of Al composites prepared by high-energy ball milling; effect of processing conditions. J. Alloys Compd. 643, S172–S177 (2015). https://doi.org/10.1016/j.jallcom.2015.01.018

J. ManuelMendoza-Duarte, I. Estrada-Guel, F.C. Robles-Hernandez, C. Carreño-Gallardo, C. López-Meléndez, R. Martínez-Sánchez, Mechanical and microstructural response of an aluminum nanocomposite reinforced with carbon-based particles. Mater. Res. (2016). https://doi.org/10.1590/1980-5373-MR-2015-0625

M. Baig, H.R. Ammar, A.H. Seikh, Thermo-mechanical responses of nanocrystalline Al-Fe alloy processed using mechanical alloying and high frequency heat induction sintering. Mater. Sci. Eng. A 655, 132–141 (2016). https://doi.org/10.1016/j.msea.2015.12.077

Acknowledgments

The authors gratefully thank D. Lardizabal-Gutierrez for his valuable technical assistance and C. Leyva, K. Campos., and E. Lestarjette for their help with SEM and XRD characterization for the experimental part of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Rights and permissions

About this article

Cite this article

Mendoza-Duarte, J.M., Robles-Hernandez, F.C., Rocha-Rangel, E. et al. Increase of the mechanical response of pure aluminum by grain refinement retained with an alternative rapid sintering route. Journal of Materials Research 36, 1328–1340 (2021). https://doi.org/10.1557/s43578-021-00176-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00176-8