Abstract

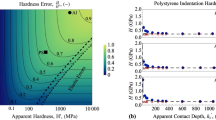

A correction is needed to minimize errors in contact area caused by surface tilt in nanoindentation. Surface tilt decreases the contact area calculated using standard analyses that assume the tested surface is not tilted and thus results in overestimation of hardness and elastic modulus. Both the direction of tilt with respect to the pyramid face and the angle of the pyramidal probe are important when characterizing error caused by surface tilt. Here, a geometric model was used to create contour plots from which the area correction factor can be directly determined using only the ratios of side lengths measured from an image of the triangular nanoindentation impression. Contour plots for Berkovich, cube corner, and two nonstandard pyramidal probe geometries are given. The efficacy of the method was demonstrated in the correction of Berkovich nanoindentation on facets in freshly prepared poly(methyl methacrylate) with surface tilts as high as 6°.

Graphic Abstract

Similar content being viewed by others

Data availability

Data can be available upon reasonable request to the corresponding author.

References

R.B. King, Elastic analysis of some punch problems for a layered medium. Int. J. Solids Struct. 23(12), 1657 (1987)

J.H. Strader, S. Shim, H. Bei, W.C. Oliver, G.M. Pharr, An experimental evaluation of the constant β relating the contact stiffness to the contact area in nanoindentation. Philos. Mag. 86(33), 5285 (2006)

A. Bolshakov and G. M. Pharr: Inaccuracies in Sneddon's solution for elastic indentation by a rigid cone and their implications for nanoindentation data analysis, in Thin Films: Stresses and Mechanical Properties VI, edited by W. W. Gerberich, H. Gao, J.-E. Sundgren, and S. P. Baker (Mater. Res. Soc. Symp. Proc. 436, San Francisco, CA, USA, 1997), p. 189.

J.E. Jakes, C.R. Frihart, J.F. Beecher, R.J. Moon, D.S. Stone, Experimental method to account for structural compliance in nanoindentation measurements. J. Mater. Res. 23(4), 1113 (2008)

T. Chudoba, N.M. Jennett, Higher accuracy analysis of instrumented indentation data obtained with pointed indenters. J. Phys. D. Appl. Phys. 41(21), 215407 (2008)

E. Berkovich, Three-faceted diamond pyramid for micro-hardness testing. Ind. Diam. Rev. 11(127), 129 (1951)

W.C. Oliver, G.M. Pharr, Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564 (1992)

W.C. Oliver, G.M. Pharr, Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19(1), 3 (2004)

Z.-H. Xu, X. Li, Effect of sample tilt on nanoindentation behaviour of materials. Philos. Mag. 87(16), 2299 (2007)

J.D. Ellis, S.T. Smith, R.J. Hocken, Alignment uncertainties in ideal indentation styli. Precis. Eng. 32(3), 207 (2008)

M. Saket Kashani and V. Madhavan: The effect of surface tilt on nanoindentation results, in Volume 10: Mechanics of Solids and Structures, Parts A and B (Proc. of the ASME, International Mechanical Engineering Congress and Exposition. Seattle, WA, USA 2007, 1067 (2007)

M.S. Kashani, V. Madhavan, Analysis and correction of the effect of sample tilt on results of nanoindentation. Acta Mater. 59(3), 883 (2011)

H. Huang, H. Zhao, C. Shi, L. Zhang, Using residual indent morphology to measure the tilt between the triangular pyramid indenter and the sample surface. Meas. Sci. Technol. 24(10), 105602 (2013)

C. Shi, H. Zhao, H. Huang, L. Xu, L. Ren, M. Bai, J. Li, X. Hu, Effects of indenter tilt on nanoindentation results of fused silica: an investigation by finite element analysis. Mater. Trans. 54(6), 958 (2013)

A. Leitner, V. Maier-Kiener, D. Kiener, Extraction of flow behavior and Hall-Petch parameters using a nanoindentation multiple sharp tip approach. Adv. Eng. Mater. 19(4), 1600669 (2017)

G. Kermouche, J.L. Loubet, J.M. Bergheau, Extraction of stress–strain curves of elastic–viscoplastic solids using conical/pyramidal indentation testing with application to polymers. Mech. Mater. 40(4), 271 (2008)

D.J. Morris, A.M. Vodnick, R.F. Cook, Radial fracture during indentation by acute probes II: experimental observations of cube-corner and Vickers indentation. Int. J. Fract. 136(1), 265 (2005)

I. M. Gelfand and T. Alekseyevskaya (Gelfand): in Geometry, edited by I. M. Gelfand and T. Alekseyevskaya (Gelfand) (Springer New York, New York, NY, 2020), pp. 231–401.

J.E. Jakes, R.S. Lakes, D.S. Stone, Broadband nanoindentation of glassy polymers: Part II Viscoplasticity. J. Mater. Res. 27(02), 475 (2012)

H. Chakraborty, A. Sinha, N. Mukherjee, D. Ray, and P. Protim Chattopadhyay: A study on nanoindentation and tribological behaviour of multifunctional ZnO/PMMA nanocomposite. Mater. Lett. 93, 137 (2013).

P. Jindal, M. Sain, N. Kumar, Mechanical characterization of PMMA/MWCNT composites under static and dynamic loading conditions. Mater. Today Proc. 2(4), 1364 (2015)

T. Jin, X. Niu, G. Xiao, Z. Wang, Z. Zhou, G. Yuan, X. Shu, Effects of experimental variables on PMMA nano-indentation measurements. Polym. Test. 41, 1 (2015)

I.N. Sneddon, Relation between load and penetration in axisymmetric Boussinesq problem for punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965)

J.E. Jakes, Improved methods for nanoindentation Berkovich probe calibrations using fused silica. J. Mater. Sci. 53(7), 4814 (2018)

A. F. Yee and M. T. Takemori: Dynamic bulk and shear relaxation in glassy polymers. I. Experimental techniques and results on PMMA. J. Polym. Sci. Polym. Phys. Ed. 20(Copyright 1982, IEE), 205 (1982).

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid, J.-Y. Tinevez, D.J. White, V. Hartenstein, K. Eliceiri, P. Tomancak, A. Cardona, Fiji: an open-source platform for biological-image analysis. Nat. Methods 9(7), 676 (2012)

Acknowledgments

The authors acknowledge Bernie Becker for helpful discussion and verification on the theory.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jakes, J.E., Stauffer, D. Contact area correction for surface tilt in pyramidal nanoindentation. Journal of Materials Research 36, 2189–2197 (2021). https://doi.org/10.1557/s43578-021-00119-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00119-3