Abstract

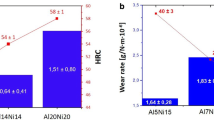

The adjusted mixture of ordered body-centered cubic (bcc) structure, referred to as B2, and disordered bcc structure, referred to as A2, in high-entropy alloys (HEAs) leads to a substantial enhancement in their strength. Via selecting elements in B2/A2 HEAs, their microstructure could be optimized for desirable properties (e.g., strength, ductility, and wear resistance) to meet requirements for specific applications. In this study, we delved into the effect of interplay between Cr and Ti in shaping the microstructure, mechanical properties, and wear resistance of Co-free B2/A2 CrFeNiAl alloy. CrxFeNiAl and CrxFeNiAlTi0.5 (x = 0, 0.5, 1, and 1.5) alloys were synthesized. For Ti-free FeNiAl alloy, the introduction of Cr led to a transition from a single B2 phase to a mixture of B2 and A2 phases, along with a morphological change from A2 nanoparticles embedded in B2 phase to an alternating lamellar eutectic structure or cellular structure. While in the Ti-containing FeNiAlTi0.5 alloy, Cr induced a shift from a microstructure of B2 + Fe2Ti Laves phase to one consisting of B2 + A2 phases. Ti increased the B2 lattice parameter. Notably, the strength, hardness, and ductility of the HEA increase with increasing Cr content, attributed to the precipitation and augmentation of A2 phase, Cr-facilitated solution hardening, and elimination of the Laves phase. The incorporation of Ti enhances strength at the expense of ductility. For the FeNiAl alloy, the developed oxide film caused by frictional heating during wear test enhanced its wear resistance, surpassing that of harder Cr0.5FeNiAl alloy. The wear resistance was improved with added Cr. Ti also contributes positively to wear resistance due to increased mechanical strength and the formation of a protective oxide scale.

Impact statement

This study demonstrates the effectiveness of modifying mechanical and wear properties of Co-free CrFeNiAl alloy via tuning the B2/A2 phase ratio by adjusting elemental contents. It is shown that Ti increases the B2 lattice parameter, enhancing strength and wear resistance, but compromising ductility. Inclusion of Cr, regardless of Ti’s presence, results in simultaneous improvements in the strength, ductility, and wear resistance. The elucidated mechanism would help design effective HEAs with optimal combinations of mechanical and wear properties.

Graphical abstract

Similar content being viewed by others

Data availability

This article is self-containing, including all data.

References

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004)

E.P. George, D. Raabe, R.O. Ritchie, Nat. Rev. Mater. 4, 515 (2019)

M.H. Tsai, J.W. Yeh, Mater. Res. Lett. 2, 107 (2014)

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, Y. Yang, Mater. Today 19, 349 (2016)

J.W. Yeh, JOM 65, 1759 (2013)

E.P. George, R.O. Ritchie, MRS Bull. 47(2), 145 (2022)

Z. He, N. Jia, H. Wang, H. Yan, Y. Shen, J. Mater. Sci. Technol. 86, 158 (2021)

Z.F. He, N. Jia, D. Ma, H.L. Yan, Z.M. Li, D. Raabe, Mater. Sci. Eng. A 759, 437 (2019)

H. Song, J. Yang, Y.H. Jo, T. Song, H.S. Kim, B.-J. Lee, S. Lee, J. Alloys Compd. 797, 465 (2019)

D.V. Louzguine-Luzgin, J. Jiang, G.R. Aripov, Y.P. Ivanov, V.I. Polkin, MRS Bull. 47(2), 134 (2022)

T.M. Butler, M.L. Weaver, J. Alloys Compd. 691, 119 (2017)

B. Gludovatz, R.O. Ritchie, MRS Bull. 47(2), 176 (2022)

J. Dąbrowa, G. Cieślak, M. Stygar, K. Mroczka, K. Berent, T. Kulik, M. Danielewski, Intermetallics 84, 52 (2017)

Y. Dong, L. Jiang, Z. Tang, Y. Lu, T. Li, J. Mater. Eng. Perform. 24, 4475 (2015)

C. Zhang, Y. Yang, MRS Bull. 47(2), 158 (2022)

X. Zhou, X. Wang, L. Fey, S. He, I. Beyerlein, P. Cao, J. Marian, MRS Bull. 48(7), 777 (2023)

W. Jiang, Y. Zhu, Y. Zhao, Front. Mater. 8, 792359 (2022)

S. Sonal, J. Lee, Metals (Basel) 11(12), 1980 (2021)

M.-H. Chuang, M.-H. Tsai, W.-R. Wang, S.-J. Lin, J.-W. Yeh, Acta Mater. 59, 6308 (2011)

S. Wang, L. Chen, Q. Li, S. Wang, M. Wu, S. Yang, D. Xiang, Metals (Basel) 12, 191 (2022)

W. Zhang, Z. Ma, C. Li, C. Guo, D. Liu, H. Zhao, L. Ren, J. Mater. Sci. Technol. 114, 102 (2022)

B. Liu, J. Wang, Y. Liu, Q. Fang, Y. Wu, S. Chen, C.T. Liu, Intermetallics 75, 25 (2016)

C.H. Tsau, S.X. Lin, C.H. Fang, Mater. Chem. Phys. 186, 534 (2017)

C. Li, J.C. Li, M. Zhao, Q. Jiang, J. Alloys Compd. 504, 515 (2010)

W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai, J.-W. Yeh, Intermetallics 26, 44 (2012)

M. Wu, G. Diao, J.F. Yuan, D. Fraser, J. Li, R. Chung, D.Y. Li, Wear 523, 204765 (2023)

M. Wu, K. Chen, Z. Xu, D.Y. Li, Wear 462–463, 203493 (2020)

T.T. Shun, W.J. Hung, Adv. Mater. Sci. Eng. 2018, 5826467 (2018)

M. Löbel, T. Lindner, T. Mehner, T. Lampke, Entropy (Basel) 20, 505 (2018)

M. Wu, R.C. Setiawan, D.Y. Li, Wear 492–493, 204231 (2022)

A. Takeuchi, A. Inoue, Mater. Trans. 46, 2817 (2005)

X. Gao, Y. Lu, B. Zhang, N. Liang, G. Wu, G. Sha, J. Liu, Y. Zhao, Acta Mater. 141, 59 (2017)

Y. Lu, X. Gao, L. Jiang, Z. Chen, T. Wang, J. Jie, H. Kang, Y. Zhang, S. Guo, H. Ruan, Y. Zhao, Z. Cao, T. Li, Acta Mater. 124, 143 (2017)

W. Jiao, T. Li, X. Chang, Y. Lu, G. Yin, Z. Cao, T. Li, J. Alloys Compd. 902, 163814 (2022)

S. Guo, C. Ng, C.T. Liu, Mater. Res. Lett. 1, 228 (2013)

T. Borkar, B. Gwalani, D. Choudhuri, T. Alam, A.S. Mantri, M.A. Gibson, R. Banerjee, Intermetallics 71, 31 (2016)

L. Zhang, D. Zhou, B. Li, Mater. Lett. 216, 252 (2018)

X. Chen, J.Q. Qi, Y.W. Sui, Y.Z. He, F.X. Wei, Q.K. Meng, Z. Sun, Mater. Sci. Eng. A 681, 25 (2017)

Y. Guo, L. Liu, W. Zhang, K. Yao, Z. Zhao, J. Shang, J. Qi, M. Chen, R. Zhao, F. Wu, J. Alloys Compd. 889, 161676 (2021)

J.L. Li, Z. Li, Q. Wang, C. Dong, P.K. Liaw, Acta Mater. 197, 10 (2020)

L. Li, Z. Li, A. Kwiatkowski da Silva, Z. Peng, H. Zhao, B. Gault, D. Raabe, Acta Mater. 178, 1 (2019)

J.E. Morral, S. Chen, J. Phase Equilib. Diffus. 42, 673 (2021)

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, J. Banhart, Acta Mater. 59, 182 (2011)

Z. Jiang, W. Chen, Z. Xia, W. Xiong, Z. Fu, Intermetallics 108, 45 (2019)

Y.X. Zhuang, X.L. Zhang, X.Y. Gu, Entropy (Basel) 20, 987 (2018)

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, Z.Q. Hu, Mater. Sci. Eng. A 527, 7210 (2010)

T.T. Shun, L.Y. Chang, M.H. Shu, Mater. Sci. Eng. A 556, 170 (2012)

N.D. Stepanov, D.G. Shaysultanov, R.S. Chernichenko, M.A. Tikhonovsky, S.V. Zherebtsov, J. Alloys Compd. 770, 194 (2019)

G. Diao, A. He, D.Y. Li, M. Wu, Z. Xu, W. Li, Q.Y. Li, Mater. Sci. Eng. A 856, 143910 (2022)

A. Gali, E.P. George, Intermetallics 39, 74 (2013)

J.H. Zhang, T. Jin, Y.B. Xu, Z.Q. Hu, J. Mater. Sci. Technol. 18, 159 (2002)

L. Huang, M. Long, W. Liu, S. Li, Mater. Lett. 293, 129718 (2021)

S. Gao, T. Kong, M. Zhang, X. Chen, Y.W. Sui, Y.J. Ren, J.Q. Qi, F.X. Wei, Y.Z. He, Q.K. Meng, Z. Sun, J. Mater. Res. 34, 819 (2019)

Z. Wang, Q. Fang, J. Li, B. Liu, Y. Liu, J. Mater. Sci. Technol. 34, 349 (2018)

C. Lee, G. Song, M.C. Gao, R. Feng, P. Chen, J. Brechtl, Y. Chen, K. An, W. Guo, J.D. Poplawsky, S. Li, A.T. Samaei, W. Chen, A. Hu, H. Choo, P.K. Liaw, Acta Mater. 160, 158 (2018)

Q. He, Y. Yang, Front. Mater. 5, 42 (2018)

M.M. Khruschov, Wear 28, 69 (1974)

Y. Zhang, H. Wu, X. Yu, D. Tong, Corros. Sci. 200, 110211 (2022)

L. Sánchez, M.P. Hierro, F.J. Pérez, Oxid. Met. 71, 173 (2009)

P. Guo, S. Ma, M. Jiao, P. Lv, J. Xing, L. Xu, Z. Huang, Materials (Basel) 15, 557 (2022)

T.F.J. Quinn, Wear 216, 262 (1998)

H. So, Wear 184, 161 (1995)

A. Erdogan, K.M. Doleker, S. Zeytin, JOM 71, 3499 (2019)

J. Chen, X. Zhou, W. Wang, B. Liu, Y. Lv, W. Yang, D. Xu, Y. Liu, J. Alloys Compd. 760, 15 (2018)

S.W. Yang, Oxid. Met. 15, 375 (1981)

M. Abbasi, D.I. Kim, J.H. Shim, W.S. Jung, J. Alloys Compd. 658, 210 (2016)

X. Tang, D.Y. Li, Scr. Mater. 58, 1090 (2008)

R. Yılmaz, A.O. Kurt, A. Demir, Z. Tatlı, J. Eur. Ceram. Soc. 27, 1319 (2007)

I. Radu, D.Y. Li, Wear 259, 453 (2005)

M. Wu, K. Chen, Z. Xu, D.Y. Li, Wear 462–463, 203493 (2020)

Acknowledgments

The authors are grateful for financial support from Alberta Innovates, the Natural Sciences and Engineering Research Council of Canada, Trimay and Mitacs.

Funding

This work is supported by the Natural Sciences and Engineering Research Council of Canada, Alberta Innovates, Trimay, Mitacs.

Author information

Authors and Affiliations

Contributions

M.W. and D.L. conceived the idea, designed the experiments, and wrote the manuscript. R.K.S. helped make the alloy samples and conducted the SEM examination. A.H. carried out the TEM examination and data analysis. M.W. and G.D. evaluated the alloys’ properties and completed additional characterization work. D.C. helped in the data analysis and reviewed and edited the manuscript. D.L. supervised the research project. All authors contributed to general discussion.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, M., Sim, R.K., He, A. et al. Enhancing mechanical performance and wear resistance of Co-free B2/A2 CrFeNiAl alloy via Cr and Ti adjustment. MRS Bulletin 49, 25–37 (2024). https://doi.org/10.1557/s43577-023-00624-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-023-00624-2