Abstract

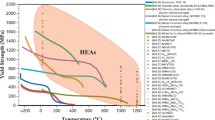

The search for materials that meet contemporary engineering challenges requires the exploration of structures only found beyond those achieved through conventional synthesis and processing techniques. These far-from-equilibrium materials are achievable through the application of one or multiple coupled extreme environments, allowing the systems to be kinetically trapped, or meta-equilibrated, in unique conditions across several length scales during processing. Here, we provide an overview of how coupled extreme environments, such as high temperature, high load or shear, irradiation and oxidation, may lead to the formation of materials with unique hierarchical microstructures with tolerance to harsh conditions beyond the capabilities of conventional materials. We discuss fundamentals, challenges, and opportunities of unprecedented performances for metals, oxides, and boride ceramics highlighting the distinctive characteristics that make these far-from-equilibrium materials exceptional for use in fields where multiple extreme conditions are met, such as the aerospace, nuclear energy, and energy-storage applications.

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

A.J. Shahani, A.J. Clarke, MRS Bull. 45(11), 906 (2020)

Y. Fan, T. Iwashita, T. Egami, Nat. Commun. 8, 15417 (2017)

Y. Takamura, R.V. Chopdekar, A. Scholl, A. Doran, J.A. Liddle, B. Harteneck, Y. Suzuki, Nano Lett. 6, 1287 (2006)

B.-Y. Li, F. Chen, H.-N. Xiong, L. Tang, J.-X. Shao, Z.-J. Yang, Results Phys. 28, 104681 (2021)

D. Yu, B. Zhang, J. Yin, Y. Wang, X. Liu, M.J. Reece, Z. Huang, J. Am. Ceram. Soc. 105, 76 (2022)

W. Knafo, S. Araki, G. Lapertot, D. Aoki, G. Knebel, D. Braithwaite, Nat. Phys. 16, 942 (2020)

B. Schuster, F. Fujara, B. Merk, R. Neumann, T. Seidl, C. Trautmann, Nucl. Instrum. Methods Phys. Res. B 277, 45 (2012)

N. Nafsin, R.H.R. Castro, J. Mater. Res. 32, 166 (2017)

L. Zhang, J. Wu, F. Chen, X. Li, J.M. Schoenung, Q. Shen, J. Asian Ceram. Soc. 1, 114 (2013)

M. Sokol, S. Kalabukhov, M.P. Dariel, N. Frage, J. Eur. Ceram. Soc. 34, 4305 (2014)

A. Bokov, J.A. Aguiar, M.L. Gong, A. Nikonov, R.H.R. Castro, J. Phys. Chem. C 122, 26344 (2018)

K.C. Bedin, A.L.M. Freitas, A. Tofanello, I. Rodríguez-Gutiérrez, F.L. Souza, Int. J. Ceram. Eng. Sci. 2, 204 (2020)

R.H.R. Castro, Curr. Opin. Solid State Mater. Sci. 25, 100911 (2021)

R.H.R. Castro, D. Gouvêa, J. Am. Ceram. Soc. 99, 1105 (2016)

T. Jiang, Y. Liu, Z. Wang, W. Sun, J. Qiao, K. Sun, J. Power Sources 248, 70 (2014)

M.C. Steil, D. Marinha, Y. Aman, J.R.C. Gomes, M. Kleitz, J. Eur. Ceram. Soc. 33, 2093 (2013)

H.J. Avila-Paredes, K. Choi, C.-T. Chen, S. Kim, J. Mater. Chem. 19, 4837 (2009)

J.F. Rufner, D. Kaseman, R.H.R. Castro, K. van Benthem, J. Am. Ceram. Soc. 99, 1951 (2016)

M. Lachal, H. El Khal, D. Bouvard, J.-M. Chaix, R. Bouchet, M.C. Steil, J. Am. Ceram. Soc. 104, 3845 (2021)

O. Guillon, Int. J. Ceram. Eng. Sci. 3, 100 (2021)

H. Watzman, Nature 462, 712 (2009)

Y. Deng, J.S. Schilling, Phys. Rev. B 99, 85137 (2019)

H. Assadi, H. Kreye, F. Gärtner, T. Klassen, Acta Mater. 116, 382 (2016)

R.S. Mishra, Z.Y. Ma, Mater. Sci. Eng. R Rep. 50(1–2), 1 (2005). https://doi.org/10.1016/j.mser.2005.07.001

R. Kalsar, X. Ma, J. Darsell, D. Zhang, K. Kappagantula, D.R. Herling, V.V. Joshi, Mater. Sci. Eng. A 883, 142575 (2022). https://doi.org/10.1016/j.msea.2021.142575

X. Li, W. Tang, A.P. Reynolds, W.A. Tayon, C.A. Brice, J. Mater. Process. Technol. 229, 191 (2016)

N.R. Overman, S.A. Whalen, M.E. Bowden, M.J. Olszta, K. Kruska, T. Clark, E.L. Stevens, J.T. Darsell, V.V. Joshi, X. Jiang, K.F. Mattlin, S.N. Mathaudhu, Mater. Sci. Eng. A 701, 56 (2017)

S. Whalen, N. Overman, V. Joshi, T. Varga, D. Graff, C. Lavender, Mater. Sci. Eng. A 755, 278 (2019)

D. Catalini, D. Kaoumi, A.P. Reynolds, G.J. Grant, J. Nucl. Mater. 442 (1–3) (Suppl. 1), S112 (2013). https://doi.org/10.1016/j.jnucmat.2012.11.054

S. Hanke, J.F. dos Santos, J. Mater. Process. Technol. 247, 257 (2017)

O.G. Rivera, P.G. Allison, J.B. Jordon, O.L. Rodriguez, L.N. Brewer, Z. McClelland, W.R. Whittington, D. Francis, J. Su, R.L. Martens, N. Hardwick, Mater. Sci. Eng. A 694, 1 (2017)

S. Whalen, S. Jana, D. Catalini, N. Overman, J. Sharp, J. Electron. Mater. 45, 3390 (2016)

B. Gwalani, M. Olszta, S. Varma, L. Li, A. Soulami, E. Kautz, S. Pathak, A. Rohatgi, P.V. Sushko, S. Mathaudhu, C.A. Powell, A. Devaraj, Commun. Mater. 1, 85 (2020). https://doi.org/10.1038/s43246-020-00087-x

B. Gwalani, Q. Pang, A. Yu, W. Fu, L. Li, M. Pole, C. Roach, S.N. Mathaudhu, T. Ajantiwalay, M. Efe, S. Hu, M. Song, A. Soulami, A. Rohatgi, Y. Li, P.V. Sushko, A. Devaraj, ACS Omega 7, 13721 (2022)

M. Komarasamy, X. Li, S.A. Whalen, X. Ma, N. Canfield, M.J. Olszta, T. Varga, A.L. Schemer-Kohrn, A. Yu, N.R. Overman, S.N. Mathaudhu, G.J. Grant, J. Mater. Sci. 56, 12864 (2021)

T. Liu, M. Olszta, B. Gwalani, C. Park, S. Mathaudhu, A. Devaraj, Materialia 15, 101049, (2021). https://doi.org/10.1016/j.mtla.2021.101049

N.R. Overman, M.J. Olszta, M. Bowden, X. Li, A. Rohatgi, S.N. Mathaudhu, G.J. Grant, S.A. Whalen, Mater. Des. 211, 110151 (2021). https://doi.org/10.1016/j.matdes.2021.110151

M. Song, J. Darsell, S. Jana, J. Mater. Sci. 57, 12055 (2022). https://doi.org/10.1007/s10853-022-07355-w

X. Li, C. Zhou, N. Overman, X. Ma, N. Canfield, K. Kappagantula, J. Schroth, G. Grant, J. Manuf. Process. 65, 397 (2021)

Y. Hovanski, P. Upadhyay, J. Carsley, T. Luzanski, B. Carlson, M. Eisenmenger, A. Soulami, D. Marshall, B. Landino, S. Hartfield-Wunsch, JOM 67, 1045 (2015)

B.S. Taysom, N. Overman, M. Olszta, M. Reza-E-Rabby, T. Skszek, M. DiCiano, S. Whalen, Int. J. Mach. Tools Manuf. 169, 103798 (2021). https://doi.org/10.1016/j.ijmachtools.2021.103798

S. Whalen, M. Olszta, M. Reza-E-Rabby, T. Roosendaal, T. Wang, D. Herling, B.S. Taysom, S. Suffield, N. Overman, J. Manuf. Process. 71, 699 (2021)

B.S. Taysom, M. Reza-E-Rabby, X. Ma, M. DiCiano, T. Skszek, S. Whalen, “Fabrication of Aluminum Alloy 6063 Tubing from Secondary Scrap with Shear Assisted Processing and Extrusion,” in Light Metals 2022, The Minerals, Metals & Materials Series, ed. by D. Eskin (Springer, Cham, 2022), pp. 294–300

X. Jiang, S.A. Whalen, J.T. Darsell, S.N. Mathaudhu, N.R. Overman, Mater. Charact. 123, 166 (2017)

D. Catalini, D. Kaoumi, A.P. Reynolds, G.J. Grant, Metall. Mater. Trans. A 46, 4730 (2015)

L. Silvestroni, H.-J. Kleebe, W.G. Fahrenholtz, J. Watts, Sci. Rep. 7(1), 40730 (2017)

W.G. Fahrenholtz, E.J. Wuchina, W.E. Lee, Y. Zhou (eds.), Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications (Wiley, Hoboken, 2014)

L. Silvestroni, N. Gilli, A. Migliori, D. Sciti, J. Watts, G.E. Hilmas, W.G. Fahrenholtz, Compos. B Eng. 183, 107618 (2020). https://doi.org/10.1016/j.compositesb.2019.107618

N. Gilli, J. Watts, W.G. Fahrenholtz, D. Sciti, L. Silvestroni, Compos. B Eng. 226, 109344 (2021)

L. Silvestroni, N. Gilli, A. Sangiorgi, A. Corozzi, S. Filipovic, N. Obradović, L. Ortiz-Membrado, E. Jiménez-Piqué, W.G. Fahrenholtz, J. Adv. Ceram. (in press)

J.S. Moya, S. Lopez-Esteban, C. Pecharromán, Prog. Mater. Sci. 52, 1017 (2007)

L. Silvestroni, D. Sciti, J. Am. Ceram. Soc. 94(6), 1920 (2011). https://doi.org/10.1111/j.1551-2916.2010.04317.x

L. Silvestroni, D. Sciti, F. Monteverde, K. Stricker, H.-J. Kleebe, J. Am. Ceram. Soc. 100(4), 1760 (2017). https://doi.org/10.1111/jace.14738

L. Silvestroni, S. Failla, V. Vinokurov, I. Neshpor, O. Grigoriev, Scr. Mater. 160, 1 (2019). https://doi.org/10.1016/j.scriptamat.2018.09.024

L. Silvestroni, D. Sciti, J. Alloys Compd. 602, 346 (2014). https://doi.org/10.1016/j.jallcom.2014.02.133

J.F. Bartolome, M. Diaz, J. Requena, J.S. Moya, A.P. Tomsia, Acta Mater. 47, 3891 (1999)

W.G. Fahrenholtz, D.T. Ellerby, R.E. Loehman, J. Am. Ceram. Soc. 83, 1279 (2000)

W.H. Tuan, R.J. Brook, J. Eur. Ceram. Soc. 6, 31 (1990)

W.H. Tuan, S.M. Liu, C.J. Ho, C.S. Lin, T.J. Yang, D.M. Zhang, Z.Y. Fu, J.K. Guo, J. Eur. Ceram. Soc. 25, 3125 (2005)

A.A. Khan, J.C. Labbe, J. Mater. Sci. 32, 3829 (1997)

J. Huang, C. Li, J. Mater. Res. 9, 3153 (1994)

E.W. Neuman, G.E. Hilmas, W.G. Fahrenholtz, J. Am. Ceram. Soc. 96, 47 (2013)

E.W. Neuman, H.J. Brown-Shaklee, J.L. Watts, G. Hilmas, W. Fahrenholtz, Am. Ceram. Soc. Bull. 92, 36 (2013)

L. Silvestroni, K. Stricker, D. Sciti, H.J. Kleebe, Acta Mater. 151, 216 (2018)

L. Silvestroni, S. Mungiguerra, D. Sciti, G.D. Di Martino, R. Savino, Corros. Sci. 159, 108125 (2019)

G.B. Olson, Science 277, 1237 (1997)

L. Feng, W.G. Fahrenholtz, G.E. Hilmas, L. Silvestroni, J. Am. Ceram. Soc. 105, 5032 (2022)

E.P. George, R.O. Ritchie, MRS Bull. 47(2), 145 (2022)

Y. Shang, J. Brechtl, C. Pistidda, P.K. Liaw, “Mechanical Behavior of High-Entropy Alloys: A Review,” in High-Entropy Materials: Theory, Experiments, and Applications, ed. by J. Brechtl, P.K. Liaw (Springer, Cham, 2021), pp. 435–522. https://doi.org/10.1007/978-3-030-77641-1_10

R. Feng, B. Feng, M.C. Gao, C. Zhang, J.C. Neuefeind, J.D. Poplawsky, Y. Ren, K. An, M. Widom, P.K. Liaw, Adv. Mater. 33, 2102401 (2021)

R.O. Ritchie, R.M. Cannon, B.J. Dalgleish, R.H. Dauskardt, J.M. McNaney, “On the Strength and Toughness of Structural Ceramics Bonded to Metals,” in Advanced Materials ’93. Ceramics, Powders, Corrosion and Advanced Processing (Elsevier, Amsterdam, 1994), pp. 409–412. https://doi.org/10.1016/B978-0-444-81991-8.50104-7

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, Science 345, 1153 (2014)

F. Granberg, K. Nordlund, M.W. Ullah, K. Jin, C. Lu, H. Bei, L.M. Wang, F. Djurabekova, W.J. Weber, Y. Zhang, Phys. Rev. Lett. 116, 135504 (2016). https://doi.org/10.1103/PhysRevLett.116.135504

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004)

C.M. Rost, E. Sachet, T. Borman, A. Moballegh, E.C. Dickey, D. Hou, J.L. Jones, S. Curtarolo, J.-P. Maria, Nat. Commun. 6, 8485 (2015)

A. Sarkar, L. Velasco, D. Wang, Q. Wang, G. Talasila, L. de Biasi, C. Kübel, T. Brezesinski, S.S. Bhattacharya, H. Hahn, B. Breitung, Nat. Commun. 9(1), 3400 (2018)

D. Bérardan, S. Franger, D. Dragoe, A.K. Meena, N. Dragoe, Phys. Status Solidi Rapid Res. Lett. 10, 328 (2016)

S. Jiang, T. Hu, J. Gild, N. Zhou, J. Nie, M. Qin, T. Harrington, K. Vecchio, J. Luo, Scr. Mater. 142, 116 (2018)

J. Gild, J. Braun, K. Kaufmann, E. Marin, T. Harrington, P. Hopkins, K. Vecchio, J. Luo, J. Mater. 5, 337 (2019)

Y. Qin, J.X. Liu, F. Li, X. Wei, H. Wu, G.J. Zhang, J. Adv. Ceram. 8, 148 (2019)

J. Gild, Y. Zhang, T. Harrington, S. Jiang, T. Hu, M.C. Quinn, W.M. Mellor, N. Zhou, K. Vecchio, J. Luo, Sci. Rep. 6, 37946 (2016)

G. Tallarita, R. Licheri, S. Garroni, R. Orrù, G. Cao, Scr. Mater. 158, 100 (2019)

Y. Zhang, Z. Bin Jiang, S.K. Sun, W.M. Guo, Q.S. Chen, J.X. Qiu, K. Plucknett, H.T. Lin, J. Eur. Ceram. Soc. 39, 3920 (2019)

C. Toher, C. Oses, M. Esters, D. Hicks, G.N. Kotsonis, C.M. Rost, D.W. Brenner, J.-P. Maria, S. Curtarolo, MRS Bull. 47(2), 194 (2022)

P. Sarker, T. Harrington, C. Toher, C. Oses, M. Samiee, J.-P. Maria, D.W. Brenner, K.S. Vecchio, S. Curtarolo, Nat. Commun. 9, 4980 (2018). https://doi.org/10.1038/s41467-018-07160-7

E. Castle, T. Csanádi, S. Grasso, J. Dusza, M. Reece, Sci. Rep. 8, 8609 (2018). https://doi.org/10.1038/s41598-018-26827-1

A. Nisar, C. Zhang, B. Boesl, A. Agarwal, Ceram. Int. 46, 25845 (2020)

J. Gild, A. Wright, K. Quiambao-Tomko, M. Qin, J.A. Tomko, M. Shafkat bin Hoque, J.L. Braun, B. Bloomfield, D. Martinez, T. Harrington, K. Vecchio, P.E. Hopkins, J. Luo, Ceram. Int. 46, 6906 (2020)

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017)

P. Kolodziej, J.V. Bowles, C. Roberts, “Optimizing Hypersonic Sharp Body Concepts from a Thermal Protection System Perspective,” 8th AIAA International Space Planes and Hypersonic Systems Technologies Conference (Norfolk, April 27–30, 1998), pp. 556–571

D.E. Glass, “Ceramic Matrix Composite (CMC) Thermal Protection Systems (TPS) and Hot Structures for Hypersonic Vehicles,” 15th AIAA Space Planes and Hypersonic Systems and Technologies Conference (Dayton, April 28–May 1, 2008), pp. 1–36

M. Miller-Oana, P. Neff, M. Valdez, A. Powell, M. Packard, L.S. Walker, E.L. Corral, J. Am. Ceram. Soc. 98, 1300 (2015)

G. Tallarita, R. Licheri, S. Garroni, S. Barbarossa, R. Orrù, G. Cao, J. Eur. Ceram. Soc. 40, 942 (2020)

E.A. Olevsky, S.M. Rolfing, A.L. Maximenko, Sci. Rep. 6, 33408 (2016)

J. Gild, K. Kaufmann, K. Vecchio, J. Luo, Scr. Mater. 170, 106 (2019)

L. Feng, W.G. Fahrenholtz, G.E. Hilmas, F. Monteverde, J. Eur. Ceram. Soc. 41, 92 (2021)

M. Qin, S. Shivakumar, T. Lei, J. Gild, E.C. Hessong, H. Wang, K.S. Vecchio, T.J. Rupert, J. Luo, J. Eur. Ceram. Soc. 42, 5164 (2022)

L. Backman, J. Gild, J. Luo, E.J. Opila, Acta Mater. 197, 20 (2020)

L. Backman, J. Gild, J. Luo, E.J. Opila, Acta Mater. 197, 81 (2020)

T.M. Butler, K.J. Chaput, J.R. Dietrich, O.N. Senkov, J. Alloys Compd. 729, 1004 (2017)

F. Müller, B. Gorr, H.-J. Christ, J. Müller, B. Butz, H. Chen, A. Kauffmann, M. Heilmaier, Corros. Sci. 159, 108161 (2019). https://doi.org/10.1016/j.corsci.2019.108161

Z. Gong, Q. Zeng, W. Zhao, K. Guan, P. Rao, Q. Zeng, J. Liu, Z. Feng, J. Am. Ceram. Soc. 103(10), 5900 (2020)

B.E. Hopkins, J. Less-Common Met. 2, 172 (1960)

R.L. Fleischer, JOM, 37, 16 (1985)

Acknowledgments

L.S. acknowledges the contribution from Prof. W.G. Fahrenholtz and Prof. G.E. Hilmas from Missouri University of Science and Technology in Rolla for strength tests above 1600°C.

Funding

L.S. acknowledges the funds received from the NATO Science for Peace and Security Programme under Grant No. MYP-G5767 (SUSPENCE) and from the US AFOSR through the Cooperative Agreement No. FA9550-21-1-0399 (NACREOUS) with M.-J. Pan as contract monitor. R.C. thanks DMR Ceramics 2015650 and FAPESP 2022/04150-6. C.P. acknowledges support by the Laboratory Directed Research and Development program at the Pacific Northwest National Laboratory (PNNL) as part of the Solid Phase Processing Science Initiative. PNNL is a multiprogram national laboratory operated by Battelle for the US Department of Energy under Contract No. DEAC05-76RL01830. K.A.A. gratefully acknowledges financial support from the National Research Council Research Associateship Program. L.M.R. and K.A.A. are grateful to D. Miracle for insightful discussions and review. Any views expressed here are those of the authors’ and do not reflect the official policy or position of the US Air Force, Department of Defense, or the US Government. Distribution A; cleared for public release (AFR-2022-4227).

Author information

Authors and Affiliations

Contributions

All authors contributed equally.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silvestroni, L., Rueschhoff, L.M., Acord, K.A. et al. Synthesis of far-from-equilibrium materials for extreme environments. MRS Bulletin 47, 1143–1153 (2022). https://doi.org/10.1557/s43577-022-00454-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-022-00454-8