Abstract

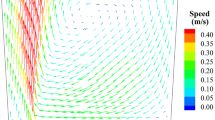

Manufacturing of high dimension steel rings impose several technological challenges. The lack of understanding of the principles and practices of quenching can result in inadequate hardness, excessive distortion or scrapping of costly machined components. This paper presents the results of an analytical study of the parameters of the quenching operation, among them the fluid dynamics of the agitation in the quenching media. Velocity components of the fluid were measured using an anemometer inside the quenching tank. Uniformity of agitation is compared with a Computational Fluid Dynamics (CFD) simulation. The CFD results revealed the impact of quench tank design, configuration and operation of impellers.

Similar content being viewed by others

References

E. Martínez, C. Márquez, J. Rodríguez, F. Fernández and A. Pérez. Microstructural evolution of high dimension rings of steel AISI 4140. IMRS 2011, Cancun, Mexico, August 2011 (unpublished).

W.T. Cook. Review of Selected Steel-related Factors Controlling Distortion in Heattreatable Steels, Heat Treatment of Metals, v 26 n 2, 1999, pp 27–36.

G.E. Totten, C.E. Bates and N.A. Clinton, “Cooling Curve Analysis — Chapter 2”, in Handbook of Quenchants and Quenching Technology, 1993, ASM International, Materials Park, OH, p. 69–128.

G.M. Webster and G.E. Totten, “Cooling Curve Analysis - Data Acquisition”, in Heat Treating: Proceedings of the 16 th Conference, Ed. J.L. Dossett and R.E. Luetje, ASM International, Materials Park, OH, 1996, p. 427–434.

G. E. Totten, E. Howes, and M. A.H, Steel Heat Treatment Handbook. 1997, Marcel Dekker, Inc. p. 157.

Z. Ke-Jian “Reduction and Elimination of Quench Distortion by CRB Method”, Beijing HuaLi Fine Chemical Company Ltd. Beijing 102200, China.

J. C. Chaves. “The effect of surface conditions and high temperature oxidation on quenching performance of 4140 steel in mineral oil”, Ph.D. Thesis, Worcester Polytechnic Institute, 2001.

S. Kernazhitskiy. “Numerical modeling of a flow in a quench tank”, Master in Science Thesis, Portland State University, 2003.

D. Rondeau. “The effects of part orientation and fluid flow on heat transfer around a cylinder”, Master in Science Thesis, Worcester Polytechnic Institute, 2004.

J.B. Hernández-Morales, A.M. Dueñas-Pérez, M. Díaz- Cruz, R. Yates. Mathematical Model of the Microstructural Response of a Medium-Carbon, Low-Alloy Steel Quenched in a Fluidized Bed. Proceedings of the 24th ASM Heat Treating Society Conference, September 17-19, 2007.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Márquez, C., Martínez, E., Cárdenas, J. et al. Study of the Impact of Quenching Process Parameters in High Dimension Rings of Steel AISI 4140. MRS Online Proceedings Library 1372, 151–156 (2011). https://doi.org/10.1557/opl.2012.121

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2012.121