Abstract

Lowering the silicon germanium (SiGe) deposition temperature from the current 450°C to below 250°C will enable processing Micro Electro-Mechanical Systems (MEMS) on flexible polymer instead of on rigid silicon substrates or glass carriers. A major disadvantage of such a low temperature deposition is that the films are amorphous, with high hydrogen content and yield poor electrical and mechanical properties. To ensure films suitable for MEMS applications, a post-deposition laser annealing (LA) treatment is used. It is essential that the contact resistance between the SiGe MEMS structural layer and any lower electrode is minimized. In this work we investigate what beneficial effect a LA treatment can have on the contact resistivity of an initially amorphous SiGe MEMS structural layer with a bottom TiN electrode. We report a minimum contact resistivity of 2.14×10-3 Ωcm2.

Similar content being viewed by others

References

A. Witvrouw, “The road to flexible MEMS integration. In: Passive and Electromechanical Materials and Integration,” Mater. Res. Soc. Symp. Proc.,vol. 1075, 2008

S. Patil et al., “Performance of thin film silicon MEMS on flexible plastic substrates,” Sensors and Actuators A, vol. 144, pp. 201–206, 2008

N. Young et al., “Low Temperature Poly-Si on Flexible Polymer Substrates for Active Matrix Displays and Other Applications,” Mat. Res. Soc. Symp. Proc., vol. 769, 2003

S. Xiao et al., “A novel fabrication process of MEMS devices on polyimide flexible substrates,” Microelectronic Engineering, vol. 85 no. 2, pp. 452–457, 2008

X. Ma et al., “Laser-Induced Crystallization of a Si1-xGex Microstructure,” J. Mater. Synth. Process., vol. 10, no. 1, January 2002

S. Sedky et al., “Optimal Conditions for Micromachining Si1-xGex at 210ºC”, JMEMS, vol. 16, no. 3, pp. 581–588, June 2007

J. El-Rifai et al., “Laser-induced Crystallization of SiGe MEMS Structural Layers Deposited at Temperatures below 250°C,” Mater. Res. Soc. Symp. Proc., vol. 1153, A19.03, 2009

M. Gromova et al., “Characterization and strain gradient optimization of PECVD poly-SiGe layers for MEMS applications,” Sensors and Actuators A, vol. 130–131, pp. 403–410, 2006

J. El-Rifai et al., “Selective Laser Annealing for Improved SiGe MEMS Structural Layers at 210ºC,” Proc. IEEE MEMS 2010, pp. 324–327, 2010

G. Claes et al., “Improvement of the poly-SiGe electrode contact technology for MEMS,” J. Micromech. Microeng., vol. 20, 2010

H. Lin et al., “An Evaluation of Test Structures for Measuring the Contact Resistance of 3-D Bonded Interconnects,” ICMTS, pp. 123–127, March 2008

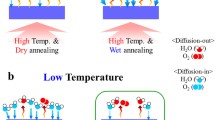

A. T. Voutsas et al., “The Impact of Annealing Ambient on the Performance of Excimer-Laser-Annealed Polysilicon Thin-Film Transistors,” J. Electrochem. Soc., vol. 149, no. 9, pp. 3500–3505, 1999

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

El-Rifai, J., Witvrouw, A., Aziz, A.A. et al. Contact Resistivity of Laser Annealed SiGe for MEMS Structural Layers Deposited at 210°C. MRS Online Proceedings Library 1299, 205 (2011). https://doi.org/10.1557/opl.2011.54

Published:

DOI: https://doi.org/10.1557/opl.2011.54