Abstract

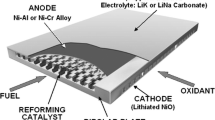

High-temperature carbonate fuel cells are recognized as the cleanest and most efficient power generation option for commercial and industrial customers. The firstgeneration carbonate fuel cell plants have shown an electrical efficiency of 45–48%.The electrolyte in this fuel cell is a mixture of alkali carbonates, and it operates at a highenough temperature that the heat by-product can be used for cogeneration applications such as district heating, hot water, process steam, and absorption chilling for air conditioning. Alternatively, the heat by-product can be used with an unfired gas turbine for additional electrical generation. Depending on location, application, and load size, carbonate fuel cells are expected to achieve an overall energy efficiency of 65–80% in cogeneration and combined cycle applications. The cell hardware uses commonly available stainless steels. Electrode materials are nickel-based. Furthermore, standard, well-established manufacturing processes are employed. Therefore, carbonate fuel cells are well positioned to be cost-competitive with alternative technologies. Significant progress has been made in the development, manufacturing, product engineering, and field operation of carbonate fuel cell technology. Megawatt and submegawatt units are operating worldwide. A comprehensive review of carbonate fuel cell technology and materials are presented in this article.

Similar content being viewed by others

References

Fuel Cell Handbook, 6th Ed., EG&G Technical Services Inc., Science Applications International Corp. (U.S. Department of Energy/National Energy Technology Laboratory, November 2002).

M. Farooque, S. Katikaneni, and H. Maru, in Proc. Carbonate Fuel Cell Technology V, PV99-20 (Electrochemical Society, Pennington, N.J., 1999) p. 47.

C. Yuh, R. Johnsen, M. Farooque, and H. Maru, J. Power Sources 56 (1995) p. 1.

J. Hoffmann, C. Yuh, and A. Godula Jepek, “Electrolyte and Material Challenges,” Chapter 67 in Handbook of Fuel Cells: Fundamentals, Technology, and Applications, Vol. 4 (John Wiley & Sons, Hoboken, N.J., 2003).

M. Primerano, J. Li, C. Yuh, and T. Lucas, U.S. patent 6,372,3744 (April 16, 2002).

C. Yuh, M. Farooque, and H. Maru, in Proc. Carbonate Fuel Cell Technology V, PV99-20 (Electrochemical Society, Pennington, N.J., 1999) p. 189.

FuelCell Energy Inc. press release, September 14, 2004.

Rights and permissions

About this article

Cite this article

Farooque, M., Yuh, C. & Maru, H.C. Carbonate Fuel Cell Technology and Materials. MRS Bulletin 30, 602–606 (2005). https://doi.org/10.1557/mrs2005.168

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs2005.168