Abstract

Thermal-barrier coatings (TBCs) are complex, defected, thick films made of zirconia-based refractory ceramic oxides. Their widespread applicability has necessitated development of high throughput, low cost materials manufacturing technologies. Thermal plasmas and electron beams have been the primary energy sources for processing of such systems. Electron-beam physical vapor deposition (EBPVD) is a sophisticated TBC fabrication technology for rotating parts of aero engine components, while atmospheric plasma sprays (APS) span the range from rotating blades of large power generation turbines to afterburners in supersonic propulsion engines. This article presents a scientific description of both contemporary manufacturing processes (EBPVD, APS) and emerging TBC deposition technologies based on novel extensions to plasma technology (suspension spray, plasma spray-PVD) to facilitate novel compliant and low thermal conductivity coating architectures. TBCs are of vital importance to both performance and energy efficiency of modern turbines with concomitant needs in process control for both advanced design and reliable manufacturing.

Similar content being viewed by others

References

A. Kulkarni, Z. Wang, T. Nakamura, S. Sampath, A. Goland, H. Herman, J. Allen, J. Ilavsky, G. Long, J. Frahm, R.W. Steinbrech, Acta Mater. 51, 2457 (2003).

A. Flores Renteria, B. Saruhan, U. Schulz, H.-J. Raetzer-Scheibe, J. Haug, A. Wiedenmann, Surf. Coat. Technol. 201, 2611 (2006).

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, F.S. Pettit, Prog. Mater. Sci. 46 (5) 505 (2001).

Y. Liu, T. Nakamura, G. Dwivedi, A. Valarezo, S. Sampath, J. Am. Ceram. Soc. 91 (12), 4036 (2008).

Y. Liu, T. Nakamura, V. Srinivasan, A. Vaidya, A. Gouldstone, S. Sampath Acta Mater. 55, 4667 (2007).

C.A. Johnson, J.A. Ruud, R. Bruce, D. Wortman, Surf. Coat. Technol. 108, 80 (1998).

T.A. Taylor, US Patent 5, 073, 433 (1989).

D.M. Gray, Y.C. Lau, C.A. Johnson, M.P. Boron, W.A. Nelson, US Patent 5,830,586 (1996).

P. Fauchais, G. Montavon, J. Therm. Spray Technol. 19 (1–2), 226 (2010)

D.D. Hass, H.N.G. Wadley, US Patent Appl. 2008/0131611 A1 (2008).

K. Von Niessen, M. Gindrat, J. Therm. Spray Technol. 20 (4), 736 (2011).

U. Schulz, B. Saruhan, K. Fritscher, C. Leyens, Int. J. Appl. Ceram. Technol. 1, 302 (2004).

A. Flores Renteria, B. Saruhan, J. Ilavsky, A.J. Allen, Surf. Coat. Tech. 201 (8)4781 (2007).

U. Schulz, S.G. Terry, C.G. Levi, Mater. Sci. Eng. A 360, 319 (2003).

A. Vaidya, V. Srinivasan, T. Streibl, M. Friis, W. Chi, S. Sampath, Mater. Sci. Eng., A 497, 239 (2008).

S. Kuroda, T.W. Clyne, Thin Solid Films 200 (1), 49 (1991).

T. Nakamura, Y. Liu, Int. J. Solids Struct. 44 (6), 1990 (2007).

W. Chi, S. Sampath, H. Wang, J. Am. Ceram. Soc. 91 (8), 2636 (2008).

G. Dwivedi, T. Nakamura, S. Sampath, J. Am. Ceram. Soc. 94, 104 (2011).

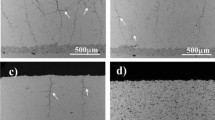

H.B. Guo, H. Murakami, S. Kuroda, Mater. Trans. 47 (42), 308 (2006).

H.B. Guo, R. Vaßen, D. Stöver, Surf. Coat. Technol. 186 (3), 353 (2004).

K. Ito, H. Kuriki, M. Watanabe, S. Kuroda, M. Enoki, Mater. Trans. 53, 671 (2012).

A. Kulkarni, A. Goland, H. Herman, A. Allen, J. Ilavsky, G. Long, C. Johnson, J. Ruud, J. Am. Ceram. Soc. 87 (7), 1294 (2004).

J. Karthikeyan, C.C. Berndt, J. Tikkanen, S. Reddy, H. Herman, Mater. Sci. Eng., A 238 (2), 275 (1997).

T. Bhatia, A. Ozturk, L. Xie, E. Jordan, B. Cetegen, M. Gell, X. Ma, N. Padture, J. Mater. Res. 17, 2363 (2002).

R. Rampon, C. Filiatre, G. Bertrand, J. Therm. Spray Technol. 17 (1), 105 (2008).

C. Delbos, J. Fazilleau, V. Rat, J.F. Coudert, P. Fauchais, B. Pateyron Plasma Chem. Plasma Process. 26 (4), 393 (2006).

H. Kassner, R. Siegert, D. Hathiramani, R. Vassen, D. Stoever, J. Therm. Spray Technol. 17 (1), 115 (2008).

H. Kaßner, A. Stuke, M. Rödig, R. Vaßen, D. Stöver, Ceramic Engineering and Science Proceedings 29 (4) 147 (2009).

A. Guignard, G. Mauer, R. Vaßen, D. Stöver, J. Therm. Spray Technol. 21 416 (2012).

A. Guignard, doctoral thesis, Ruhr University, Bochum, Germany (2012).

A. Hospach, G. Mauer, R. Vassen, D. Stover, J. Therm. Spray Technol. 20 (1–2), 116 (2011).

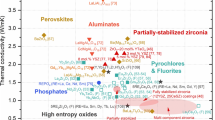

D. Zhu, R. Miller, Int. J. Appl. Ceram. Technol. 1, 86 (2004).

R. Vassen, X. Cao, F. Tietz, D. Basu, D. Stöver, J. Am. Ceram. Soc. 83 (8), 2023 (2000).

M. Jarligo, D.E. Mack, R. Vassen, D. Stöver, J. Therm. Spray Technol. 18 (2), 187 (2009).

Y. Tan, J. Longtin, S. Sampath, H. Wang, J. Am. Ceram. Soc. 92 (3), 710 (2009).

R.A. Miller, J.L. Smialek, R.G. Garilick, in Science and Technology of Zirconia I, A.H. Heuer, L.W. Hobbs, Eds. (American Ceramic Society, Columbus, OH, 1981), p. 241.

C. Mercer, J.R. Williams, D.R. Clarke, A.G. Evans, Proc. R. Soc. 463 (2081), 1393(2007).

Acknowledgments

We are grateful to Dr. Gopal Dwivedi of Stony Brook University for his assistance in integrating the figures for this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sampath, S., Schulz, U., Jarligo, M.O. et al. Processing science of advanced thermal-barrier systems. MRS Bulletin 37, 903–910 (2012). https://doi.org/10.1557/mrs.2012.233

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2012.233