Abstract

The review article describes the composition, working, and benefits of the electrodynamic screen (EDS) film, a self-cleaning surface technology that can be retrofitted onto solar and thermal energy collectors. The EDS film avoids the use of water and robotic parts that are the common cleaning techniques used in solar/thermal power plants and thus emerges as a viable and scalable solution to the soiling problem faced recurrently by these plants. The article summarizes different experiments conducted to improve the efficiency of the EDS film in terms of reflectivity and performance. Field test results are also included to underscore the success of the EDS film operation.

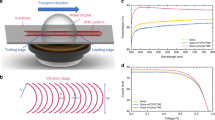

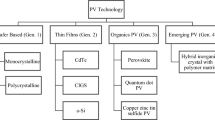

Dust build-up or soiling on thermal and solar energy collector surfaces is a major problem and its cleaning is a major issue for solar energy conversion. Here, a self-cleaning technology is described as a scalable and viable solution to clear the surfaces. EDS film technology does not require water, manual labor, or moving parts to function, and the power needed to operate EDS is almost negligible and can be derived from the harvesting device itself. The EDS films thereby help mitigate the energy loss caused by soiling in solar and thermal harvesting systems. An EDS film with reflective or transparent electrodes can be retrofitted on concentrated solar power mirrors and on photovoltaic (PV) panels to sustain and aid their unhindered reflection and absorption of incident sunlight, respectively. We report experiments and describe methods used to increase the reflectivity of the electrodes of an EDS film. Results obtained from lab test setups and field test units that define the functionality, reflectivity, and stability of the electrodes on the EDS films are also presented. Field test results that compare and report the performance of PV panel output current over long periods of testing, with and without EDS films are also discussed. Test results from 3-month outdoor testing, which demonstrate recovery back to >95% of the pristine system, after decrease to 80–90% before EDS film activation, are also shown.

Similar content being viewed by others

References

Sarver T., Al-Qaraghuli A., and Kazmerski L.L.: A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 22, 698–733 (2013).

Mazumder M.K., Horenstein M.N., Stark J.W., Girouard P., Sumner R., Henderson B., Sadder O., Hidetaka I., Biris A.S., and Sharma R.: Characterization of electrodynamic screen performance for dust removal from solar panels and solar hydrogen generators. IEEE Trans. Ind. Appl. 49(4), (2013).

Mazumder M.K., Horenstein M.N., Joglekar N.R., Sayyah A., Stark J.W., Bernard A.A.R., Garner S.M., Yellowhair J.E., Lin H.Y., Eriksen R.S., Griffin A.C., Gao Y., La Centra R., and Lloyd A.H.: Mitigation of dust impact on solar collectors by water-free cleaning with transparent electrodynamic film. IEEE J. Photovolt. 7(5), (2017).

Mazumder M.K., Stark J.W., Heiling C., Liu M., Bernard A., Horenstein M.N., Garner S., and Lin H.Y.: Development of transparent electrodynamic screens on ultrathin flexible glass film substrates for retrofitting solar panels and mirrors for self-cleaning function. MRS Adv. 1(15), (2016).

Horenstein M.N., Mazumder M.K., and Sumner R.C.: Predicting particle trajectories on an electrodynamic screen—Theory and experiment. J. Electrost. 71(3), 185–188 (2013).

Bernard A.R., Eriksen R., Lin H.Y., Yellowhair J., Garner S., Sayyah A., Griffin A., Lloyd A., Gao Y., La Centra R., Morales C., Lakshmanan R., Horenstein M., and Mazumder M.: Design, development and evaluation of electrodynamic screens for self-cleaning solar panels and concentrating mirrors. In 44th PVSC_IEEE Conference, Session: Soiling; Device, Panel and Materials Durability and Accelerated Testing—Area 9.

Voué M., Dahmouchène N., and De Coninck J.: Annealing of polymer films with embedded silver nanoparticles. In (ICSE-V) 519(9).

Chu C-T., Fuqua P.D., and Barrie J.D.: Corrosion characterization of durable silver coatings by electrochemical impedance spectroscopy and accelerated environmental testing. Appl. Optic. 45(7), 1583–1593 (2006).

Folgner K.A., Chu C-T., Lingley Z.R., Kim H.I., Yang J-M., and Barrie J.D.: Environmental durability of protected silver mirrors prepared by plasma beam sputtering. Appl. Optic. 56(4), C75 (2017).

Joglekar N., Guzelsu E., Mazumder M., Botts A., and Ho C.: A levelized cost metric for EDS-based cleaning of mirrors in CSP power plants (ASME 2014 8th international conference on energy sustainability collocated with the ASME 2014 12th international conference on fuel cell science, engineering and technology). Paper No. ES2014-6496, pp. V001T02A026.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernard, A.R., Eriksen, R., Horenstein, M.N. et al. Dust settles, we don’t: The electrodynamic screen—A self-cleaning technology for concentrated solar power mirrors and photovoltaic panels. MRS Energy & Sustainability 5, 11 (2018). https://doi.org/10.1557/mre.2018.12

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/mre.2018.12