Abstract

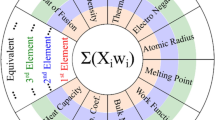

There is a genuine need to shorten the development period for new materials with desired properties. In this work, machine learning (ML) was conducted on a dataset of the elastic moduli of 219 bulk-metallic glasses (BMGs) and another dataset of the critical casting diameters (Dmax) of 442 BMGs. The resulting ML model predicted the moduli and Dmax of BMGs in good agreement with most experimentally measured values, and the model even identified some errors reported in the literature. This work indicates the great potential of ML in design of advanced materials with target properties.

Similar content being viewed by others

References

W.H. Wang: The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 57, 487–656 (2012).

R. Ramprasad, R. Batra, G. Pilania, A. Mannodi-Kanakkithodi, and C. Kim: Machine learning in materials informatics: Recent applications and prospects. NPJ Comput. Mater. 3, 54 (2017).

P. Raccuglia, K.C. Elbert, P.D.F. Adler, C. Falk, M.B. Wenny, A. Mollo, M. Zeller, S.A. Friedler, J. Schrier, and A.J. Norquist: Machine-learningassisted materials discovery using failed experiments. Nature 533, 73–76 (2016).

S. Ramakrishna, T.Y. Zhang, W.C. Lu, Q. Qian, J.S.C. Low, J.H.R. Yune, D.Z.L. Tan, S. Bressan, S. Sanvito, and S.R. Kalidindi: Materials informatics. J. Intell. Manuf. 29, 1–20 (2018).

Y.T. Sun, H.Y. Bai, M.Z. Li, and W.H. Wang: Machine learning approach for prediction and understanding of glass-forming ability. J. Phys. Chem. Lett. 8, 3434–3439 (2017).

L. Ward, S.C. O’Keeffe, J. Stevick, G.R. Jelbert, M. Aykol, and C. Wolverton: A machine learning approach for engineering bulk metallic glass alloys. Acta Mater. 159, 102–111 (2018).

F. Ren, L. Ward, T. Williams, K.J. Laws, C. Wolverton, J. Hattrick-Simpers, and A. Mehta: Accelerated discovery of metallic glasses through iteration of machine learning and high-throughput experiments. Sci. Adv. 4, 1566 (2018).

Z.Q. Liu and Z.F. Zhang: Strengthening and toughening metallic glasses: The elastic perspectives and opportunities. J. Appl. Phys. 115, 163505 (2014).

Z. Long, W. Liu, M. Zhong, Z. Yun, M. Zhao, G. Liao, and Z. Chen: A new correlation between the characteristics temperature and glass-forming ability for bulk metallic glasses. J. Therm. Anal. Calorim. 3, 1645–1660 (2018).

J.Q. Wang, W.H. Wang, H.B. Yu, and H.Y. Bai: Correlations between elastic moduli and molar volume in metallic glasses. Appl. Phys. Lett. 94, 121904 (2009).

K. Zhao, Z. Bai, L. Zhang, and G. Liu: Correlation between atomic size and elastic properties/glass transition temperature in metallic glasses. Sci. China: Phys., Mech. Astron. 60, 106121 (2017).

M.X. Xia, Q.G. Meng, S.G. Zhang, C.L. Ma, and J.G. Li: Thermodynamic characteristics of metallic glass-forming liquids. Acta Phys. Sin. 55, 6543–6549 (2006).

Q. Jiang, B.Q. Chi, and J.C. Li: A valence electron concentration criterion for glass-formation ability of metallic liquids. Appl. Phys. Lett. 82, 2984–2986 (2003).

A. Inoue, and A. Takeuchi: Recent development and application products of bulk glassy alloys. Acta Mater. 59, 2243–2267 (2011).

K.J. Laws, D.B. Miracle, and M. Ferry: A predictive structural model for bulk metallic glasses. Nat. Commun. 6, 8123 (2015).

H. Peng, S.S. Li, and T.Y. Huang: A glass forming ability indicator of Mg-based metallic glasses using atomic radius and electronegativity. J. Tsinghua Univ. 8, 1188–1192 (2010).

Z.P. Lu, C.T. Liu, and Y.D. Dong: Effects of atomic bonding nature and size mismatch on thermal stability and glass-forming ability of bulk metallic glasses. J. Non-Cryst. Solids 341, 93–100 (2004).

P. Pyykkö and M. Atsumi: Molecular single-bond covalent radii for elements 1–118. Chem. Eur. J. 15, 186–197 (2009).

J.E. Huheey, E.A. Keiter, and R.L. Keiter: Inorganic Chemistry: Principles of Structure and Reactivity, 4th ed. (HarperCollins, New York, 1993), pp. 513–515.

B. Cordero, V. Gómez, A.E. Platero-Prats, M. Revés, J. Echeverría, E. Cremades, F. Barragán, and S. Alvarez: Covalent radii revisited. J. Chem. Soc., Dalton Trans. 21, 2832–2838 (2008).

D.B. Miracle: A physical model for metallic glass structures: An introduction and update. JOM 64, 846–855 (2012).

I. Guyon and A. Elisseeff: An introduction to variable and feature selection. J. Mach. Learn. Res. 3, 1157–1182 (2011).

G. James, D. Witten, R. Tibshirani, and T. Hastie: An Introduction to Statistical Learning with Applications in R (Springer, New York, 2013).

G. Zhang and H. Ge: Support vector machine with a Pearson VII function kernel for discriminating halophilic and non-halophilic proteins. Comput. Biol. Chem. 46, 16–22 (2013).

X.K. Xi, S. Li, R.J. Wang, D.Q. Zhao, M.X. Pan, and W.H. Wang: Bulk scandium-based metallic glasses. J. Mater. Res. 20, 2243–2247 (2005).

H. Choi-Yim, D. Xu, and W.L. Johnson: Ni-based bulk metallic glass formation in the Ni–Nb–Sn and Ni–Nb–Sn–X (X = B, Fe, Cu) alloy systems. Appl. Phys. Lett. 82, 1030–1032 (2003).

H. Choi-Yim, D. Xu, M.L. Lind, J.F. Löffler, and W.L. Johnson: Structure and mechanical properties of bulk glass-forming Ni-Nb-Sn alloys. Scr. Mater. 54, 187–190 (2006).

Acknowledgments

The work is supported by the National Key R&D Program of China (No. 2018YFB0704404), the Hong Kong Polytechnic University (internal grant nos. 1-ZE8R and G-YBDH), and the 111 Project of the State Administration of Foreign Experts Affairs and the Ministry of Education, China (grant no. D16002).

Author information

Authors and Affiliations

Corresponding author

Supplementary material

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1557/mrc.2019.44

Rights and permissions

About this article

Cite this article

Xiong, J., Zhang, TY. & Shi, SQ. Machine learning prediction of elastic properties and glass-forming ability of bulk metallic glasses. MRS Communications 9, 576–585 (2019). https://doi.org/10.1557/mrc.2019.44

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2019.44