Abstract

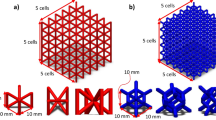

The authors design six alumina hybrid structures consisting of stretching-dominated plates and different space-filling lattices comprised of hollow tubes and perform finite element simulations to study mechanical and failure behaviors of such hybrid structures. The authors investigate the effects of three geometrical parameters on the stiffness and failure of these hybrid structures and further compare their advantages and disadvantages. The authors find that the failure modes of these hybrid structures can be tuned by altering cell unit type and geometrical parameters. Among these hybrid structures, the ones with effective support from the lattice unit cells in the stretching direction exhibit better specific stiffness and strength. By varying the lattice and plate thickness, the authors find that the relations between stiffness/failure strength and density follow a power law. When intrinsic material failure occurs, the power law exponent is 1; when buckling failure arises, the power law exponent is 3. However, by varying tube thickness, their relations follow unusual power relations with the exponent changing from nearly 0 to nearly infinity. In addition, the hybrid structures also exhibit defect insensitivity. This study shows that such hybrid structures are able to greatly expand the design space of architectured cellular materials for engineering applications.

Similar content being viewed by others

References

T.A. Schaedler, A.J. Jacobsen, and W.B. Carter: Toward lighter, stiffer materials. Science 341, 1181–1182 (2013).

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties (Cambridge University Press, Cambridge, UK, 1997).

A.G. Evans, J.W. Hutchinson, and M.F. Ashby: Multifunctionality of cellular metal systems. Prog. Mater. Sci. 43, 171–221 (1999).

H.B.G. Wadley, N.A. Fleck, and A.G. Evans: Fabrication and structural performance of periodic cellular metal sandwich structures. Compos. Sci. Technol. 63, 2331–2343 (2003).

V.S. Deshpande, N.A. Fleck, and M.F. Ashby: Effective properties of the octet truss lattice material. J. Mech. Phys. Solids 49, 1747–1769 (2001).

H.N.G. Wadley: Multifunctional periodic cellular metals. Philos. Trans. R. Soc. A 364, 31–68 (2006).

V.S. Deshpande, M.F. Ashby, and N.A. Fleck: Foam topology: bending versus stretching dominated architectures. Acta Mater. 49, 1035–1040 (2001).

T.A. Schaedler, A.J. Jacobsen, A. Torrents, A.E. Sorensen, J. Lian, J.R. Greer, L. Valdevit, and W.B. Carter: Ultralight metallic microlattices. Science 334, 962–965 (2011).

J. Bauer, S. Hengsbach, I. Tesari, R. Schwaiger, and O. Kraft: High-strength cellular ceramic composites with 3D microarchitecture. Proc. Natl. Acad. Sci. USA 111, 2453–2458 (2014).

Z.C. Eckel, C. Zhou, J.H. Martin, A.J. Jacobsen, W.B. Carter, and T.A. Schaedler: Additive manufacturing of polymer derived ceramics. Science 351, 58–62 (2016).

T. George, V.S. Deshpande, and H.N.G. Wadley: Mechanical response of carbon fiber composite sandwich panels with pyramidal truss cores. Composites Part A 47, 31–40 (2013).

K.C. Cheung, and N. Gershenfeld: Reversibly assembled cellular composite materials. Science 341, 1219–2121 (2013).

X. Zheng, H. Lee, T.H. Weisgraber, M. Shusteff, J. DeOtte, E.B. Duoss, J.D. Kuntz, M.M. Biener, Q. Ge, J.A. Jackson, S.O. Kucheyev, N.X. Fang, and C.M. Spadaccini: Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

R.B. Dinwiddie, R.R. Dehoff, P.D. Lloyd, L.E. Lowe, and J.B. Ulrich: Thermographic in-situ process monitoring of the electron-beam melting technology used in additive manufacturing. Proc. SPIE 8705, 87050K (2013).

N. Wicks, and J.W. Hutchinson: Optimal truss plates. Int. J. Solids Struct. 38, 5165–5183 (2001).

L. Valdevit, J.W. Hutchinson, and A.G. Evans: Structurally optimized sandwich panels with prismatic cores. Int. J. Solids Struct. 41, 5105–5124 (2004).

L. Valdevit, A. Pantano, H.A. Stone, and A.G. Evans: Optimal active cooling performance of metallic sandwich panels with prismatic cores. Int. J. Heat Mass Transf. 49, 3819–3830 (2006).

M.P. Bendsoe, and O. Sigmund: Topology Optimization (Springer, Berlin, 2002).

P.W. Christensen, and A. Klabering: An Introduction to Structural Optimization (Springer, Berlin, 2008).

Altair Engineering Inc. Altair OptiStruct. http://www.altairhyperworks.com/Product (2013).

Autodesk Inc. Autodesk Within. http://www.withinlab.com/software/new_index.php (2015).

Z.G. Liu, P. Liu, W. Huang, W.H. Wong, A.L. Commillus, and Y.W. Zhang: A nanolattice-plate hybrid structure to achieve a nearly linear relation between stiffness/strength and density. Mater. Design 160, 496–502 (2018).

N.A. Fleck, V.S. Deshpande, and M.F. Ashby: Micro-architectured materials: past, present and future. Proc. R. Soc. A 466, 2495–2516 (2010).

O. Rehme: Cellular design for laser freeform fabrication, Ph.D. Thesis, Hamburg-Harburg, Technical University, 2009.

E.W. Andrews, G. Gioux, P.R. Onck, and L.J. Gibson: Size effects in ductile cellular solids. Part II: experimental results. Int. J. Mech. Sci. 43, 701–713 (2001).

O. Kesler and L.J. Gibson: Size effects in metallic foam core sandwich beams. Mater. Sci. Eng., A 326, 228–234 (2002).

G. Dai and W. Zhang: Size effects of effective Young’s modulus for periodic cellular materials. Sci. China, Ser. G: Phys., Mech. Astron. 52, 1262–1270 (2009).

P.R. Onck, E.W. Andrews, and L.J. Gibson: Size effects in ductile cellular solids. Part I: modeling. Int. J. Mech. Sci. 43, 681–699 (2001).

C. Tekoglu and P.R. Onck: Size effects in the mechanical behavior of cellular materials. J. Mater. Sci. 40, 5911–5917 (2005).

ABAQUS Version 6.14. User’s Manual Version 6.14 (Providence, RI, USA, 2014).

L.J. Gibson: The mechanical behavior of cancellous bone. J. Biomech. 18, 317–328 (1985).

L.J. Gibson and M.F. Ashby: The mechanics of two-dimensional cellular materials. Proc. R. Soc. A 382, 25–42 (1982).

L.J. Gibson and M.F. Ashby: The mechanics of three-dimensional cellular materials. Proc. R. Soc. A 382, 43–59 (1982).

L.J. Gibson, M.F. Ashby, and K.E. Easterling: Structure and mechanics of the iris leaf. J. Mater. Sci. 23, 3041–3048 (1988).

L.J. Gibson, M.F. Ashby, G.N. Karam, U. Wegst, and H.R. Shercliff: The mechanical properties of natural materials II: microstructures for mechanical efficiency. Proc. R. Soc. A 450, 141–162 (1995).

L.J. Gibson: Biomechanics of cellular solids. J. Biomech. 38, 377–399 (2005).

L.C. Montemayor, W.H. Wong, Y.W. Zhang, and J.R. Greer: Insensitivity to flaws leads to damage tolerance in brittle architected meta-materials. Sci. Rep. 6, 20570 (2016).

A.J. Mateos, W. Huang, Y.W. Zhang, and J.R. Greer: Discrete-continuum duality of architected materials: failure, flaws, and fracture. Adv. Funct. Mater. 29, 1806772 (2019).

A.M. Abazari, S.M. Safavi, G. Rezazadeh, and L.G. Villanueva: Modelling the size effects on the mechanical properties of micro/nano structures. Sensors 15, 28543–28562 (2015).

J.R. Greer, and J.T.M. Hosson: Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654–724 (2011).

Acknowledgments

The support of this work by the Institute of High Performance Computing, A*STAR and use of computing resources at the A*STAR Computational Resource Centre and National Supercomputer Centre, Singapore, are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Z., Liu, P., Huang, W. et al. Mechanical and failure behaviors of lattice-plate hybrid structures. MRS Communications 10, 42–54 (2020). https://doi.org/10.1557/mrc.2019.153

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2019.153