Abstract

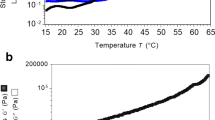

In this paper, we reviewed recent research in the field of capillary suspensions and highlight a variety of applications in the field of smart materials. Capillary suspensions are liquid-liquid-solid ternary systems where only one liquid is present in a few percent and induces a strong, capillary-induced particle network. These suspensions have a large potential for exploitation, particularly in the production of porous materials since the paste itself and the properties of the final material can be adapted. We also discussed the rheological properties of the suspension and network structure to highlight the various ways these systems can be tuned.

Similar content being viewed by others

References

E. Koos and N. Willenbacher: Capillary forces in suspension rheology. Science 331, 897–900 (2011).

T. Domenech and S. Velankar: Capillary-driven percolating networks in ternary blends of immiscible polymers and silica particles. Rheol. Acta 53, 593–605 (2014).

J. Yang and S.S. Velankar: Preparation and yielding behavior of pendular network suspensions. J. Rheol. (N. Y. N. Y). 61, 217–228 (2017).

J. Xu, L. Chen, H. Choi, H. Konish, and X. Li: Assembly of metals and nanoparticles into novel nanocomposite superstructures. Sci. Rep. 3, 1730 (2013).

T.S. Dunstan, A.A.K. Das, P. Starck, S.D. Stoyanov, and V.N. Paunov: Capillary structured suspensions from in situ hydrophobized calcium carbonate particles suspended in a polar liquid media. Langmuir 34, 442–452 (2018).

T. Domenech and S.S. Velankar: Microstructure, phase inversion and yielding in immiscible polymer blends with selectively wetting silica particles. J. Rheol. 61, 363–377 (2017).

K.D. Danov, M.T. Georgiev, P.A. Kralchevsky, G.M. Radulova, T. D. Gurkov, S.D. Stoyanov, and E.G. Pelan: Hardening of particle/oil/ water suspensions due to capillary bridges: experimental yield stress and theoretical interpretation. Adv. Colloid Interface Sci. 251, 80–96 (2018).

S. Hoffmann, E. Koos, and N. Willenbacher: Using capillary bridges to tune stability and flow behavior of food suspensions. Food Hydrocoll. 40, 44–52 (2014).

S. Wollgarten, C. Yuce, E. Koos, and N. Willenbacher: Tailoring flow behavior and texture of water based cocoa suspensions. Food Hydrocoll. 52, 167–174 (2016).

B. Bitsch, J. Dittmann, M. Schmitt, P. Scharfer, W. Schabel, and N. Willenbacher: A novel slurry concept for the fabrication of lithium-ion battery electrodes with beneficial properties. J. Power Sources 265, 81–90 (2014).

B. Bitsch, T. Gallasch, M. Schroeder, M. Börner, M. Winter, and N. Willenbacher: Capillary suspensions as beneficial formulation concept for high energy density Li-ion battery electrodes. J. Power Sources 328, 114–123 (2016).

M. Schneider, E. Koos, and N. Willenbacher: Highly conductive, printable pastes from capillary suspensions. Sci. Rep. 6, 31367 (2016).

M. Schneider, J. Maurath, S.B. Fischer, M. Weiß, N. Willenbacher, and E. Koos: Suppressing crack formation in particulate systems by utilizing capillary forces. ACS Appl. Mater. Interfaces 9, 11095–11105 (2017).

L. Jampolski, A. Sanger, T. Jakobs, G. Guthausen, T. Kolb, and N. Willenbacher: Improving the processability of coke water slurries for entrained flow gasification, Fuel 185, 102–111 (2016).

E. Koos, J. Dittmann, and N. Willenbacher: Kapillarkrafte in Suspensionen: Rheologische Eigenschaften und potenzielle Anwendungen. Chemie-lngenieur-Technik 83, 1305–1309 (2011).

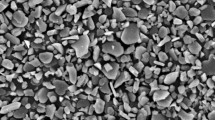

J. Dittmann and N. Willenbacher: Micro structural investigations and mechanical properties of macro porous ceramic materials from capillary suspensions. J. Am. Ceram. Soc. 97, 3787–3792 (2014).

J. Dittmann, J. Maurath, B. Bitsch, and N. Willenbacher: Highly porous materials with unique mechanical properties from smart capillary suspensions. Adv. Mater. 28, 1689–1696 (2016).

E. Koos and N. Willenbacher: Particle configurations and gelation in capillary suspensions. Soft Matter 8, 3988 (2012).

F. Bossier and E. Koos: Structure of particle networks in capillary suspensions with wetting and nonwetting fluids. Langmuir 32, 1489–1501 (2016).

A.A.K. Das, T.S. Dunstan, S.D. Stoyanov, P. Starck, and V.N. Paunov: Thermally responsive capillary suspensions. ACS Appl. Mater. Interfaces 9, 44152–44160 (2017).

T. Domenech and S.S. Velankar: On the rheology of pendular gels and morphological developments in paste-like ternary systems based on capillary attraction. Soft Matter 11, 1500–1516 (2015).

S.J. Heidlebaugh, T. Domenech, S.V. lasella, and S.S. Velankar: Aggregation and separation in ternary particle/oil/water systems with fully wettable particles. Langmuir 30, 63–74 (2014).

T. Domenech, J. Yang, S. Heidlebaugh, and S.S. Velankar: Three distinct open-pore morphologies from a single particle-filled polymer blend. Phys. Chem. Chem. Phys. 18, 4310–4315 (2016).

J. Yang, D. Roell, M. Echavarria, and S.S. Velankar: A microstructure-composition map of a ternary liquid/liquid/particle system with partially-wetting particles. Soft Matter 13, 8579–8589 (2017).

K. Hauf, K. Riazi, N. Willenbacher, and E. Koos: Radical polymerization of capillary bridges between micron-sized particles in liquid bulk phase as a low-temperature route to produce porous solid materials. Colloid Polym. Sci. 295, 1773–1785 (2017).

S. Roh, D.P. Parekh, B. Bharti, S.D. Stoyanov, and O.D. Velev: 3D Printing by multiphase silicone/water capillary inks. Adv. Mater. 29, 1–7 (2017).

J. Dittmann, E. Koos, and N. Willenbacher: Ceramic capillary suspensions: novel processing route for macroporous ceramic materials. J. Am. Ceram. Soc. 96, 391–397 (2013).

J. Maurath, J. Dittmann, N. Schultz, and N. Willenbacher: Fabrication of highly porous glass filters using capillary suspension processing. Sep. Purif Technol. 149, 470–478 (2015).

J. Maurath and N. Willenbacher: 3D printing of open-porous cellular ceramics with high specific strength. J. Eur. Ceram. Soc. 37, 4833–4842 (2017).

J. Maurath, B. Bitsch, Y. Schwegler, and N. Willenbacher: Influence of particle shape on the rheological behavior of three-phase non-Brownian suspensions. Colloids Surf. A Physicochem. Eng. Asp. 497, 316–326 (2016).

F. Bossier, L. Weyrauch, R. Schmidt, and E. Koos: Influence of mixing conditions on the rheological properties and structure of capillary suspensions. Colloids Surf. A Physicochem. Eng. Asp. 518, 85–97 (2017).

C.D. Willet, M.J. Adams, S.A. Johnson, and J.P.K. Seville: Capillary bridges between two spherical bodies. Langmuir 16, 9396–9405 (2000).

O. Pitois, P. Moucheront, and X. Chateau: Rupture energy of a pendular liquid bridge. Eur. Phys. J. BIZ, 79–86 (2001).

H.J. Butt and M. Kappl: Normal capillary forces. Adv. Colloid Interface Sci. 146, 48–60 (2009).

W. Pietsch, and H. Rumpf: Haftkraft, Kapillardruck. Fliissigkeitsvolumen und Grenzwinkel einer Fliissigkeitsbriicke zwischen zwei Kugel. Chem. Ing. Tech. 15, 885–893 (1967).

E. Koos, J. Johannsmeier, L. Schwebler, and N. Willenbacher: Tuning suspension rheology using capillary forces. Soft Matters, 6620 (2012).

C.L. Flemmer: On the regime boundaries of moisture in granular materials. Powder Technol. 66, 191–194 (1991). 12287813

F. Bossier, J. Maurath, K. Dyhr, N. Willenbacher, and E. Koos: Fractal approaches to characterize structure of capillary suspensions using rheology and confocal microscopy. J. Rheol. 62, 183 (2018).

J.-M. Piau, M. Dorget, J.-F. Palierne, and A. Pouchelon: Shear elasticity and yield stress of silica-silicone physical gels: fractal approach. J. Rheol. 43, 305–314 (1999).

H. Wu and M. Morbidelli: Model relating structure of colloidal gels to their elastic properties. Langmuir 17, 1030–1036 (2001).

E. Koos, W. Kannowade, and N. Willenbacher: Restructuring and aging in a capillary suspension. Rheol. Acta 53, 947–957 (2014).

S.S. Velankar: A non-equilibrium state diagram for liquid/fluid/particle mixtures. Soft Matter 11, 8393–8403 (2015).

Y. Zhang, M.C. Allen, R. Zhao, D.D. Deheyn, S.H. Behrens, and J. C. Meredith: Capillary foams: stabilization and functionalization of porous liquids and solids. Langmuir 31, 2669–2676 (2015).

B. Bharti, A.-L. Fameau, M. Rubinstein, and O.D. Velev: Nanocapillarity-mediated magnetic assembly of nanoparticles into ultraflexible filaments and reconfigurable networks. Nat. Mater. 14, 1104–1109 (2015).

Acknowledgments

The authors would like to acknowledge the financial support from the European Research Council under the European Union’s Seventh Framework Program (FP/2007–2013)/ERC Grant Agreement no. 335380.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hauf, K., Koos, E. Structure of capillary suspensions and their versatile applications in the creation of smart materials. MRS Communications 8, 332–342 (2018). https://doi.org/10.1557/mrc.2018.28

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2018.28