Abstract

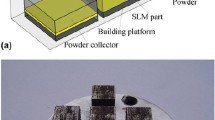

TiC/H13 nanocomposite parts were processed by selective laser melting using various energy densities; one part also underwent hot isostatic pressing (HIP). The effect of energy density and HIPing on densification, microstructure, and hardness were evaluated. It was found that the densification was not largely affected by the energy density, but the HIP-treated sample displayed a large improvement in relative density. With increasing energy density, the microstructures showed high levels of dispersion of nanoparticles, while HIP treatment coarsened the microstructure and induced agglomeration. Both HIP treatment and increased energy density lowered hardness markedly; this was likely due to annealing effects.

Similar content being viewed by others

References

J.F. Shackelford and W. Alexander: CRC Materials Science and Engineering Handbook (CRC Press, Boca Raton, FL, 2010).

I. Ibrahim, F. Mohamed, and E. Lavernia: Particulate reinforced metal matrix composites—a review. J. Mater. Sci. 26, 1137–1156 (1991).

S.C. Tjong: Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 9, 639–652 (2007).

B. AlMangour, D. Grzesiak, and J.-M. Yang: Nanocrystalline TiC-reinforced H13 steel matrix nanocomposites fabricated by selective laser melting. Mater. Des. 96, 150–161 (2016).

E. Pagounis, V. Lindroos, and M. Talvitie: Influence of reinforcement volume fraction and size on the microstructure and abrasion wear resistance of hot isostatic pressed white iron matrix composites. Metall. Mater. Trans. A 27, 4171–4181 (1996).

F. Akhtar: Microstructure evolution and wear properties of in situ synthesized TiB2 and TiC reinforced steel matrix composites. J. Alloys Compd. 459, 491–497 (2008).

W. Jiang, and P. Molian: Nanocrystalline TiC powder alloying and glazing of H13 steel using a CO2 laser for improved life of die-casting dies. Surf. Coat. Technol. 135, 139–149 (2001).

B. AlMangour, D. Grzesiak, and J.-M. Yang: Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: influence of starting TiC particle size and volume content. Mater. Des. 104, 141–151 (2016).

J. Hashim, L. Looney, and M. Hashmi: Particle distribution in cast metal matrix composites—Part I. J. Mater. Process. Technol. 123, 251–257 (2002).

F. He, Q. Han, and M.J. Jackson: Nanoparticulate reinforced metal matrix nanocomposites-a review. Int. J. Nanopart. 1, 301–309 (2008).

S. Kumar and J.-P. Kruth: Composites by rapid prototyping technology. Mater. Des. 31, 850–856 (2010).

D. Gu: Laser Additive Manufacturing (AM): Classification, Processing Philosophy, and Metallurgical Mechanisms. Laser Additive Manufacturing of High-Performance Materials (Springer, New York, 2015), pp. 15–71.

W.E. Frazier: Metal additive manufacturing: a review. J. Mater. Eng. Perform. 23, 1917–1928 (2014).

I. Gibson, D. Rosen, and B. Stucker: Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing (Springer, New York, 2014).

B. AlMangourand J.-M. Yang: Improving the surface quality and mechanical properties by shot-peening of 17-4 stainless steel fabricated by additive manufacturing. Mate. Des. 110, 914–924 (2016).

S. Bremen, W. Meiners, and A. Diatlov: Selective laser melting. Laser Tech. J. 9, 33–38 (2012).

S.L Campanelli, N. Contuzzi, A. Angelastro, and A.D. Ludovico: Capabilities and performances of the selective laser melting process. In New Trends in Technologies: Devices, Computer, Communication and Industrial Systems, edited by M. Joo Er (InTech, 2010). Available from http://www.intechopen.com/books/new-trends-in-technologies–devices computer–communication-and-industrial-systems/capabilities-and-per-formances-of-the-selective-laser-melting-process

D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe: Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int. Mater. Rev. 57, 133–164 (2012).

J.-P. Kruth, P. Mercelis, J. Van Vaerenbergh, L. Froyen, and M. Rombouts: Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyping J. 11, 26–36 (2005).

M. Rombouts, J.-P. Kruth, L. Froyen, and P. Mercelis: Fundamentals of selective laser melting of alloyed steel powders. CIRP Ann. Manuf. Technol. 55, 187–192 (2006).

G. Roberts, G. Krauss, and R. Kennedy: Tool Steels, 5th ed. (ASM International, USA, 1998), p. 38.

H. Atkinson and S. Davies: Fundamental aspects of hot isostatic pressing: an overview. Metall. Mater. Trans. A 31, 2981–3000 (2000).

A. Simchi and H. Pohl: Direct laser sintering of iron–graphite powder mixture. Mater. Sci. Eng. A 383, 191–200 (2004).

Q. Jia and D. Gu: Selective laser melting additive manufacturing of TiC/ Inconel 718 bulk-form nanocomposites: densification, microstructure, and performance. J. Mater. Res. 29, 1960–1969 (2014).

H. Niu and I. Chang: Instability of scan tracks of selective laser sintering of high speed steel powder. Scr. Mater. 41, 1229–1234 (1999).

D. Gu, Y.-C. Hagedorn, W. Meiners, K. Wissenbach, and R. Poprawe: Nanocrystalline TiC reinforced Ti matrix bulk-form nanocomposites by Selective Laser Melting (SLM): densification, growth mechanism and wear behavior. Composit. Sci. Technol. 71, 1612–1620 (2011).

M. Zhong and W. Liu: Laser surface cladding: the state of the art and challenges. Proc. Inst. Mech. Eng. C: J. Mech. Eng. Sci. 224, 1041–1060 (2010).

J.-P. Kruth, G. Levy, F. Klocke, and T. Childs: Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann.–Manufac. Technol. 56, 730–759 (2007).

D. Gu, H. Wang, D. Dai, P. Yuan, W. Meiners, and R. Poprawe: Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting. Scr. Mater. 96, 25–28 (2015).

S. Dadbakhsh and L. Hao: Effect of hot isostatic pressing (HIP) on Al composite parts made from laser consolidated Al/Fe 2 O 3 powder mixtures. J. Mater. Process. Technol. 212, 2474–2483 (2012).

Acknowledgments

One of the authors, Bandar AlMangour, gratefully acknowledges the financial support provided by the Saudi Arabia Basic Industries Corporation (SABIC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

AlMangour, B., Yu, F., Yan, JM. et al. Selective laser melting of TiC/H13 steel bulk-form nanocomposites with variations in processing parameters. MRS Communications 7, 84–89 (2017). https://doi.org/10.1557/mrc.2017.9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2017.9