Abstract

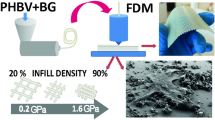

Beyond the traditional phase conversion or biphase mixing hybrid, we developed the dilute magnesium-doped wollastonite inks and three-dimensional (3D) printing approaches to fabricate the ultrahigh strength bioceramic porous scaffolds. The mechanical strength (>120 MPa) of the porous bioceramics was an order of magnitude higher than the pure wollastonite and other stoichiometric Ca-Mg silicate porous bioceramics. This abnormal but expected improvement in strength in bioceramic scaffolds is equivalent or even superior to the mechanical requirement in load-bearing bone defects. The breakthrough is totally unexpected, and it quickly opens the door for the 3D printing bioceramics manufacture and large-area segmental bone defect repair applications.

Similar content being viewed by others

References

1. S.J. Hollister: Porous scaffold design fortissue engineering. Nat. Mater. 4, 518–524 (2005).

J. Henkel, M.A. Woodruff, D.R. Epari, R. Steck, V. Glatt, I.C. Dickinson, P. F.M. Choong, M.A. Schuetz, and D.W. Hutmacher: Bone regeneration based on tissue engineering conceptions—A 21st century perspective. Bone Res. 3, 216–248 (2013).

V. Karageorgiou and D. Kaplan: Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 26, 5474–5491 (2005).

P. Kasten, I. Beyen, P. Niemeyer, R. Luginbühl, M. Bonner, and W. Richter: Porosity and pore size of /Mricalcium phosphate scaffold can influence protein production and osteogenic differentiation of human mesenchymal stem cells: an in vitro and in vivo study. Acta Biomater. 4, 1904–1915 (2008).

A.C. Jone, C.H. Arns, D.W. Hutmacher, B.K. Milthorpe, A.P. Sheppard, and M.A. Knackstedt: The correlation of pore morphology, interconnectivity and physical properties of 3D ceramic scaffolds with bone ingrowth. Biomaterials 30, 1440–1451 (2009).

A. Hoppe, N.S. Guldal, and A.R. Boccaccini: A review of the biological response to ionic dissolution products from bioactive glasses and glass-ceramics. Biomaterials 32, 2757–2774 (2013).

P. Weiss, P. Layrolle, L.P. Clergeau, B. Enckel, P. Pilet, Y. Amouriq, G. Daculsi, and B. Giumelli: The safety and efficacy of an injectable bone substitute in dental sockets demonstrated in a human clinical trial. Biomaterials 28, 3295–3305 (2007).

M. Marcacci, E. Kon, V. Moukhachev, A. Lavroukov, S. Kutepov, R. Quarto, M. Mastrogiacomo, and R. Cancedda: Stem cells associated with macroporous bioceramics for long bone repair: 6- to 7-year outcome of a pilot clinical study. Tissue Eng. 13, 947–955 (2007).

C. Wu and J. Chan: A review of bioactive silicate ceramics. Biomed. Mater. 8, 032001 (2013).

S. Xu, K. Lin, Z. Wang, J. Chang, L. Wang, J. Lu, and C. Ning: Reconstruction of calvarial defect of rabbits using porous calcium silicate bioactive ceramics. Biomaterials 29, 2588–2596 (2008).

M. Diba, O.M. Goudouri, F. Tapia, and A.R. Boccaccini: Magnesium-containing bioactive polycrystalline silicate-based ceramics and glass-ceramics for biomedical applications. Curr Opin. Solid State Mater. Sci. 18, 147–167 (2014).

M. Diba, F. Tapia, and A.R. Boccaccin: Magnesium-containing bioactive glasses for biomedical applications. Int. J. Appl. Glass Sci. 3, 221–253 (2012).

M. Descamps, T. Duhoo, F. Monchau, J. Lu, P. Hardouin, J.C. Hornez, and A. Leriche: Manufacture of macroporous p-tricalcium phosphate bioceramics. J. Eur. Ceram. Soc. 28, 149–157 (2008).

S. Deville, E. Saiz, R.K. Nalla, and A.P. Tomsia: Freezing as a path to build complex composites. Science 311, 516–518 (2006).

Q. Fu, E. Saiz, and A.P. Tomsia: Bioinspired strong and highly porous glass scaffolds. Adv. Fund. Mater. 21, 1058–1063 (2011).

S. Deville, E. Saiz, and A.P. Tomsia: Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials 27, 5480–5489 (2006).

A. Butscher, M. Bohner, S. Hofmann, L. Gauckler, and R. Muller: Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater. 7, 907–920 (2011).

C. Bergmann, M. Lindner, W. Zhang, K. Koczur, A. Kirsten, R. Telle, and H. Fischer: 3D Printing of bone substitute implants using calcium phosphate and bioactive glasses. J. Eur. Ceram. Soc. 30, 2563–2567 (2010).

A. Winkel, R. Meszaros, S. Reinsch, R. Müller, N. Travitzky, T. Fey, P. Greil, and L. Wondracze: Sintering of 3D-printed glass/HAp composites. J. Am. Ceram. Soc. 95, 3387–3393 (2012).

Q. Fu, E. Saiz, M.N. Rahaman,and A.P. Tomsia: Toward strong and tough glass and ceramic scaffolds. Adv. Funct Mater. 23, 5461–5476 (2013).

I.W. Chen and X.H. Wan: Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 40, 168–71 (2000).

C.J. Shuai, D. Gao, P. Feng, and S.P. Peng: Graphene-reinforced mechanical properties of calcium silicate scaffolds by laser sintering. RSC Adv 4, 12782–12788 (2014).

C. Wu, W. Fan, Y. Zhou, Y. Luo, M. Gelinsky, J. Chang, and Y. Xiao: 3D-printing of highly uniform CaSi03 ceramic scaffolds: preparation, characterization and in vivo osteogenesis. J. Mater. Chem. 22, 12288–12295 (2012).

H.S. Ryu, J.K. Lee, H. Kim, K.S. Hong, D.J. Kim, J.H. Lee, D.H. Lee, B.S. Chang, C.K. Lee, and S.S. Chung: Novel bioactive and degradable glass ceramics with high mechanical strength in the Ca0-Si02-B203 system. J. Biomed. Mater. Res. 68A, 79–89 (2004).

C. Wu, J. Chang, W. Zhai, S. Ni, and J. Wang: Porous akermanite scaffolds for bone tissue engineering: preparation, characterization, and in vitro studies. J. Biomed. Mater. Res. B: Appl. Biomater. 78B, 47–55 (2006).

C. Wu, Y. Ramaswamy, and H. Zreiqat: Porous diopside (CaMgSi206) scaffold: a promising bioactive material for bone tissue engineering. Acta Biomater. 6, 2237–2245 (2010).

C. Wu, J. Chang, W. Zhai, and S. Ni: A novel bioactive porous bredigite (Ca7MgSi4016) scaffold with biomimetic apatite layer for bone tissue engineering. J. Mater. Sct Mater. Med. 18, 857–864 (2007).

C. Chen, P. Watkins-Curry, M. Smoak, K. Hogan, S. Deese, G.T. McCandless, J.Y. Chan, and D.J. Hayes: Targeting calcium magnesium silicates for polycaprolactone/ceramic composite scaffolds. ACS Biomater. Sci. Eng. 1, 94–102 (2015).

K. Xie, L. Zhang, X. Yang, G. Yang, X. Wang, L. Zhang, S. Xu, H. Shao, Y. He, J. Fu, and Z. Gou: Preparation and characterization of low-temperature sintered 45S5 bioactive glass-ceramics analogues. Biomed. Glass 1, 81–93 (2015).

H. Shao, X. Yang, Y. He, J. Fu, L. Liu, L. Zhang, G. Yang, C. Gao, and Z. Gou: 3D printed bioactive glass-reinforced bioceramic scaffolds: sintering, microstructure and mechanical behavior. Biofabrication 7, 035010 (2015).

E. Champio: Sintering of calcium phosphate bioceramics. Acta Biomater. 9, 5855–5875 (2013).

L.H. Long, L.D. Chen, S.Q. Bai, J. Chang, and K.L. Lin: Preparation of dense-CaSi03 ceramic with high mechanical strength and HAp formation ability in simulated body fluid. J. Eur. Ceram. Soc. 26, 1701–1706 (2006).

A. Nadernezhad, F. Moztarzadeh, M. Hafezi, and H. Barzegar-Bafrooei: Two step sintering of a novel calcium magnesium silicate bioceramic: sintering parameters and mechanical characterization. J. Eur. Ceram. Soc. 34, 4001–4009 (2014).

T.A. Land, T.L. Martin, S. Potapenko, G.T. Palmore, and J.J. De Yoreo: Recovery of surfaces from impurity poisoning during crystal growth. Nature 399, 442–445 (1999).

Acknowledgments

This work was supported by the Zhejiang Provincial Natural Science Foundation of China (grant no. LZ14E020001), the National Natural Science Foundation of China (grant numbers 81271956 and 51221004), Science and Technology Department of Zhejiang Province Foundation (grant numbers 2015C33119 and 2014C33202), and the National “Twelfth Five-Year” Plan for Science & Technology Support of China (grant no. 2012BAI08B01).

Author information

Authors and Affiliations

Corresponding author

Additional information

These authors are co-first authors.

Supplementary Material

Supplementary Material

For supplementary material for this article, please visit http://dx.doi.org/10.1557/mrc.2015.74

Rights and permissions

About this article

Cite this article

Xie, J., Shao, H., He, D. et al. Ultrahigh strength of three-dimensional printed diluted magnesium doping wollastonite porous scaffolds. MRS Communications 5, 631–639 (2015). https://doi.org/10.1557/mrc.2015.74

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2015.74