Abstract

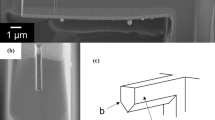

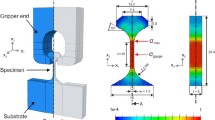

A new theta geometry was developed for microscale bending strength measurements. This new “gap” theta specimen was a modification of the arch theta specimen that enabled microscale tensile testing. The gap theta specimen was demonstrated here on single-crystal silicon, microfabricated using two different etch processes. The resulting sample strengths were described by three-parameter Weibull distributions derived from parameters determined using established arch theta strengths, assuming a specimen-geometry and -size invariant flaw distribution and an approximate loading configuration.

Similar content being viewed by others

References

M.S. Gaither, F.W. DelRio, R.S. Gates, E.R. Fuller Jr., and R.F. Cook: Strength distribution of single-crystal silicon theta-like specimens. Scripta Mater. 63, 422 (2010).

A.J. Durelli, S. Morse, and V. Parks: The theta specimen for determining tensile strength of brittle materials. Mater. Res. Standards 2, 114 (1962).

E.R. Fuller, Jr., D.L. Henann, and L. Ma: Theta-like specimens for measuring mechanical properties at the small-scale: effects of non-ideal loading. Int. J. Mater. Res. 98, 729 (2007).

G.D. Quinn, E. Fuller, D. Xiang, A. Jillavenkatesa, L. Ma, D. Smith, and J. Beall: A novel test method for measuring mechanical properties at the small-scale: the theta specimen, In Mechanical Properties and Performance of Engineering Ceramics and Composites, edited by E. Lara-Curzio (Ceramic Eng. Sci. Proc. 26, Westerville, OH, 2005), p. 117.

M.S. Gaither, F.W. DelRio, R.S. Gates, and R.F. Cook: Deformation and fracture of single-crystal silicon theta-like specimens. J. Mater. Res. 26, 2575 (2011).

M.S. Gaither, R.S. Gates, R. Kirkpatrick, R.F. Cook, and F.W. DelRio: Etching process effects on surface structure, fractur, strength, and reliability of single-crystal silicon theta-like specimens. J. Microelectromech. Syst. (2013). DOI: 10.1109/JMEMS.2012.2234724

S.D. Senturia: Microsystem Design (Kluwer Academic Publishers, Boston, 2001).

S. Tachi, K. Tsujimoto, and S. Okudaira: Low-temperature reactive ion etching and microwave plasma-etching of silicon. Appl. Phys. Lett. 52, 616 (1988).

D.L. Logan: A First Course in the Finite Element Method (Thomson, Toronto, 2007).

H.J. McSkimin and P. Andreatch Jr.: Measurement of third-order moduli of silicon and germanium. J. Appl. Phys. 35, 3312 (1964).

W. Weibull: A statistical distribution function of wide applicability. J. Appl. Mech. 18, 293 (1951).

M.T. Todinov: Probability of fracture initiated by defects. Mater. Sci. Eng. A 276, 39 (2000).

N.N. Nemeth, J.M. Manderscheid, and J.P. Gyekenyesi: Designing ceramic components with the CARES computer program. Amer. Ceram. Soc. Bull. 68, 2064 (1989).

N.A. Weil and I.M. Daniel: Analysis of fracture probabilities in nonuniformly stressed brittle materials. J. Amer. Cer. Soc. 47, 268 (1964).

T.P. Weihs, S. Hong, J.C. Bravman, and W.D. Nix: Mechanical deflection of cantilever microbeams: a new technique for testing the mechanical properties of thin films. J. Mater. Res. 3, 931 (1988).

Acknowledgment

The authors thank George D. Quinn at the National Institute of Standards and Technology (NIST) for guidance with Weibull statistics. Research was performed in part at the NIST Center for Nanoscale Science and Technology. Certain commercial equipment, instruments, or materials are identified in this report to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by NIST, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Osborn, W.A., Gaither, M.S., Gates, R.S. et al. On the bending strength of single-crystal silicon theta-like specimens Rebecca Kirkpatrick. MRS Communications 3, 113–117 (2013). https://doi.org/10.1557/mrc.2013.18

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2013.18