Abstract

In this work, filament based on ɛ-polycaprolactone (PCL) and containing the bioactive ceramics nanohydroxyapatite (nHap) and Laponite® (Lap) was prepared by the extrusion process. To obtain the material, a mass ratio of 89:10:1 (PCL:nHap:Lap) was used, and structural and morphological characterization was realized. In addition, cytotoxicity (using Allium cepa bulbs) and viability tests on L929 cells also were performed. The results showed that filament (diameter of 1.79 ± 0.17 mm) presented a good dispersion of nHap and Lap into polymeric matrices. Fourier transform infrared spectroscopy identified typical bands at 1720, 1091, and 1045 cm−1 addressed to PCL and nHAp, In addition, Lap was identified through dispersive energy system and X-ray diffraction analyses. All filaments did not exhibit cytotoxic effects.

Similar content being viewed by others

References

M. Maroulakos, G. Kamperos, L. Tayebi, D. Halazonetis, and Y. Ren: Applications of 3D printing on craniofacial bone repair: A systematic review. J. Dent 80, 1 (2019).

A.A. Zadpoor: Mechanical performance of additively manufactured meta-biomaterials. Acta Biomater. 85, 41 (2019).

R. Hedayati, S.M. Ahmadi, K. Lietaert, B. Pouran, Y. Li, H. Weinans, C.D. Rans, and A.A. Zadpoor: Isolated and modulated effects of topology and material type on the mechanical properties of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 79, 254 (2018).

B.I. Oladapo, S.A. Zahedi, and A.O.M. Adeoye: 3D printing of bone scaffolds with hybrid biomaterials. Composites, Part B 158, 428 (2019).

W. Wang, B. Huang, J.J. Byun, and P. Bártolo: Assessment of PCL/carbon material scaffolds for bone regeneration. J. Mech. Behav. Biomed. Mater. 93, 52 (2019).

Y. Du, H. Liu, J. Shuang, J. Wang, J. Ma, and S. Zhang: Microsphere-based selective laser sintering for building macroporous bone scaffolds with controlled microstructure and excellent biocompatibility. Colloids Surf., B 135, 81 (2015).

Z. Ortega, M.E. Alemán, A.N. Benítez, and M.D. Monzón: Theoretical-experimental evaluation of different biomaterials for parts obtaining by fused deposition modeling. Measurement 89, 137 (2016).

K. Friedrich: Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 1, 3 (2018).

B. Derby: Printing and prototyping of tissues and scaffolds. Science 338, 921 (2012).

L.R. Jaidev and K. Chatterjee: Surface functionalization of 3D printed polymer scaffolds to augment stem cell response. Mater. Des. 161, 44 (2019).

B. Yuan, S. Zhou, and X. Chen: Rapid prototyping technology and its application in bone tissue engineering. J. Zhejiang Univ., Sci., B 18, 303 (2017).

L. Yuan, S. Ding, and C. Wen: Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: A review. Bioact. Mater. 4, 56 (2019).

E. Malikmammadov, T.E. Tanir, A. Kiziltay, and V. Hasirci: PCL and PCL-based materials in biomedical applications. J. Biomater. Sci. Polym. Ed. 5063, 1 (2018).

Y.S. Cho, S. Choi, S.H. Lee, K.K. Kim, and Y.S. Cho: Assessments of polycaprolactone/hydroxyapatite composite scaffold with enhanced biomimetic mineralization by exposure to hydroxyapatite via a 3D-printing system and alkaline erosion. Eur. Polym. J. 113, 340 (2019).

H. Shao, J. He, T. Lin, Z. Zhang, Y. Zhang, and S. Liu: 3D gel-printing of hydroxyapatite scaffold for bone tissue engineering. Ceram. Int. 45, 1163 (2019).

Z. Chen, Z. Li, J. Li, C. Liu, C. Lao, Y. Fu, C. Liu, Y. Li, P. Wang, and Y. He: 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 39, 661 (2019).

L.C. Hwa, S. Rajoo, A.M. Noor, N. Ahmad, and M.B. Uday: Recent advances in 3D printing of porous ceramics: A review. Curr. Opin. Solid State Mater. Sci. 21, 323 (2017).

P. Chen, L. Liu, J. Pan, J. Mei, C. Li, and Y. Zheng: Biomimetic composite scaffold of hydroxyapatite/gelatin-chitosan core–shell nanofibers for bone tissue engineering. Mater. Sci. Eng. C 97, 325 (2019).

M. Nabavinia, A. Baradar, and H. Naderi-meshkin: Nano-hydroxyapatite-alginate-gelatin microcapsule as a potential osteogenic building block for modular bone tissue engineering. Mater. Sci. Eng. C 97, 67 (2019).

J.I. González Ocampo, M.M. Machado de Paula, N.J. Bassous, A.O. Lobo, C.P. Ossa Orozco, and T.J. Webster: Osteoblast responses to injectable bone substitutes of kappa-carrageenan and nano hydroxyapatite. Acta Biomater. 83, 425 (2019).

M.V.B. dos Santos, G.T. Feitosa, J.A. Osajima, R.L.P. Santos, and E.C. da Silva Filho: Desenvolvimento de biomaterial composto por hidroxiapatita e clorexidina para aplicação na cavidade oral. Cerâmica 65, 130 (2019).

A. Abdal-hay, N. Abbasi, M. Gwiazda, S. Hamlet, and S. Ivanovski: Novel polycaprolactone/hydroxyapatite nanocomposite fibrous scaffolds by direct melt-electrospinning writing. Eur. Polym. J. 105, 257 (2018).

Y. Wang, L. Liu, and S. Guo: Characterization of biodegradable and cytocompatible nano-hydroxyapatite/polycaprolactone porous scaffolds in degradation in vitro. Polym. Degrad. Stab. 95, 207 (2010).

H. Tomás, C.S. Alves, and J. Rodrigues: Laponite®: A key nanoplatform for biomedical applications? Nanomed. Nanotechnol. Biol. Med. 14, 2407 (2018).

S. Afewerki, L.S.S.M. Magalhães, A.D.R. Silva, T.D. Stocco, E.C. Silva Filho, F.R. Marciano, and A.O. Lobo: Bioprinting laponite for orthopedic applications. Adv. Healthcare Mater. 8, 1 (2019).

C. Wang, S. Wang, K. Li, Y. Ju, J. Li, Y. Zhang, J. Li, X. Liu, X. Shi, and Q. Zhao: Preparation of laponite bioceramics for potential bone tissue engineering applications. PLoS One 9, 1 (2014).

A. Mignon, D. Pezzoli, E. Prouvé, L. Lévesque, A. Arslan, N. Pien, D. Schaubroeck, J. Van Hoorick, D. Mantovani, S. Van Vlierberghe, and P. Dubruel: Preparation of laponite bioceramics for potential bone tissue engineering applications. PLoS One 136, 95 (2019).

J.M. Silva, H.S. Barud, A.B. Meneguin, V.R.L. Constantino, and S.J.L. Ribeiro: Applied clay science inorganic–organic bio-nanocomposite films based on laponite and cellulose nano fibers (CNF). Appl. Clay Sci. 168, 428 (2019).

B.P. Nair, M. Sindhu, and P.D. Nair: Polycaprolactone-laponite composite scaffold releasing strontium ranelate for bone tissue engineering applications. Colloids Surf., B 143, 423 (2016).

A.K. Gaharwar, S.M. Mihaila, A. Swami, A. Patel, S. Sant, R.L. Reis, A.P. Marques, M.E. Gomes, and A. Khademhosseini: Bioactive silicate nanoplatelets for osteogenic differentiation of human mesenchymal stem cells. Adv. Mater. 25, 3329 (2013).

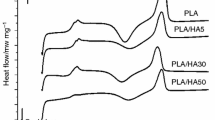

C.E. Corcione, F. Gervaso, F. Scalera, F. Montagna, A. Sannino, and A. Maffezzoli: The feasibility of printing polylactic acid—Nanohydroxyapatite composites using a low-cost fused deposition modeling 3D printer. J. Appl. Polym. Sci. 134, 1 (2016).

C. Esposito Corcione, F. Scalera, F. Gervaso, F. Montagna, A. Sannino, and A. Maffezzoli: One-step solvent-free process for the fabrication of high loaded PLA/HA composite filament for 3D printing. J. Therm. Anal. Calorim. 134, 575 (2018).

R. Haq, A. Haq, S. Wahab, and N.I. Jaimi: Fabrication process of polymer nano-composite filament for fused deposition modeling. Appl. Mech. Mater. 466, 8 (2014).

J. Fu, X. Yu, and Y. Jin: 3D printing of vaginal rings with personalized shapes for controlled release of progesterone. Int. J. Pharm. 539, 75 (2018).

Z. Muwaffak, A. Goyanes, V. Clark, A.W. Basit, S.T. Hilton, and S. Gaisford: Patient-specific 3D scanned and 3D printed antimicrobial polycaprolactone wound dressings. Int. J. Pharm. 527, 161 (2017).

D.M. Zuev, E.S. Klimashina, P.V. Evdokimov, Y.Y. Filippov, and V.I. Putlyaev: Preparation of β-Ca3(PO4)2/poly(D,L-lactide) and β-Ca3(PO4)2/poly(ε-caprolactone) biocomposite implants for bone substitution. Inorg. Mater. 54, 87 (2018).

U.K. Roopavath, S. Malferrari, A. Van Haver, F. Verstreken, S.N. Rath, and D.M. Kalaskar: Optimization of extrusion based ceramic 3D printing process for complex bony designs. Mater. Des. 162, 263 (2019).

M.R. da Cunha, M.C. Alves, A.R.A. Calegari, A. Iatecola, E.A. Galdeano, T.L. Galdeano, M.d.A.e S. Munhoz, A.M.d.G. Plepis, V.d.C.A. Martins, and M.M. Horn: In vivo study of the osteoregenerative potential of polymer membranes consisting of chitosan and carbon nanotubes. Mater. Res. 20, 819 (2017).

T. Niamsap, N.T. Lam, and P. Sukyai: Production of hydroxyapatite-bacterial nanocellulose scaffold with assist of cellulose nanocrystals. Carbohydr. Polym. 205, 159 (2019).

U. Ripamonti, J. Crooks, L. Khoali, and L. Roden: The induction of bone formation by coral-derived calcium carbonate/hydroxyapatite constructs. Biomaterials 30, 1428 (2009).

E. Torres, V. Fombuena, A. Vallés-Lluch, and T. Ellingham: Improvement of mechanical and biological properties of polycaprolactone loaded with hydroxyapatite and halloysite nanotubes. Mater. Sci. Eng. C 75, 418 (2017).

L.H. Chan-Chan, G. González-García, R.F. Vargas-Coronado, J.M. Cervantes-Uc, F. Hernández-Sánchez, A. Marcos-Fernandez, and J.V. Cauich-Rodríguez: Characterization of model compounds and poly(amide-urea) urethanes based on amino acids by FTIR, NMR, and other analytical techniques. Eur. Polym. J. 92, 27 (2017).

T. Huang, C. Fan, M. Zhu, Y. Zhu, W. Zhang, and L. Li: 3D-printed scaffolds of biomineralized hydroxyapatite nanocomposite on silk fibroin for improving bone regeneration. Appl. Surf. Sci. 467, 345 (2019).

A. Hivechi, S. Hajir Bahrami, and R.A. Siegel: Investigation of morphological, mechanical and biological properties of cellulose nanocrystal reinforced electrospun gelatin nanofibers. Int. J. Biol. Macromol. 124, 411 (2019).

Z. Lin, R. Hu, J. Zhou, Y. Ye, Z. Xu, and C. Lin: A further insight into the adsorption mechanism of protein on hydroxyapatite by FTIR-ATR spectrometry. Spectrochim. Acta Mol. Biomol. Spectrosc. 173, 527 (2017).

T. Batista, A.M. Chiorcea-Paquim, A.M.O. Brett, C.C. Schmitt, and M.G. Neumann: Laponite RD/polystyrenesulfonate nanocomposites obtained by photopolymerization. Appl. Clay Sci. 53, 27 (2011).

J. Luo, H. Zhang, J. zhu, X. Cui, J. Gao, X. Wang, and J. Xiong: 3-D mineralized silk fibroin/polycaprolactone composite scaffold modified with polyglutamate conjugated with BMP-2 peptide for bone tissue engineering. Colloids Surf., B 163, 369 (2018).

H. Bittiger, R.H. Marchessault, and W.D. Niegisch: Crystal structure of poly-ε-caprolactone. Acta Crystallogr. B 26, 1923 (2002).

M. Ravi, S. Song, J. Wang, X. Tang, and Z. Zhang: Preparation and characterization of biodegradable poly(ε-caprolactone)-based gel polymer electrolyte films. Ionics 22, 661–670 (2016).

S. Sathiyavimal, S. Vasantharaj, F. LewisOscar, A. Pugazhendhi, and R. Subashkumar: Biosynthesis and characterization of hydroxyapatite and its composite (hydroxyapatite-gelatin-chitosan-fibrin-bone ash) for bone tissue engineering applications. Int. J. Biol. Macromol. 129, 844 (2019).

A. Gloria, B. Frydman, M.L. Lamas, A.C. Serra, M. Martorelli, J.F.J. Coelho, A.C. Fonseca, and M. Domingos: The influence of poly(ester amide) on the structural and functional features of 3D additive manufactured poly(ε-caprolactone) scaffolds. Mater. Sci. Eng. C 98, 994 (2019).

M. Zanetti, L.R. Mazon, A.C. de Meneses, L.L. Silva, P.H.H. de Araújo, M.A. Fiori, and D. de Oliveira: Encapsulation of geranyl cinnamate in polycaprolactone nanoparticles. Mater. Sci. Eng. C 97, 198 (2019).

O.G. da Silva, E.C. da Silva Filho, M.G. da Fonseca, L.N.H. Arakaki, and C. Airoldi: Hydroxyapatite organofunctionalized with silylating agents to heavy cation removal. J. Colloid Interface Sci. 302, 485 (2006).

A.d.M.F. Guimarães, V.S.T. Ciminelli, and W.L. Vasconcelos: Surface modification of synthetic clay aimed at biomolecule adsorption: Synthesis and characterization. Mater. Res. 10, 37 (2007).

N.K. de Moura, I.A.W.B. Siqueira, J.P.d.B. Machado, H.W. Kido, I.R. Avanzi, A.C.M. Rennó, E.d.S. Trichês, and F.R. Passador: Production and characterization of porous polymeric membranes of PLA/PCL blends with the addition of hydroxyapatite. J. Compos. Sci. 3, 45 (2019).

B. Mangalampalli, N. Dumala, and P. Grover: Allium cepa root tip assay in assessment of toxicity of magnesium oxide nanoparticles and microparticles. J. Environ. Sci. 66, 125 (2018).

M.D. Scherer, J.C.V. Sposito, W.F. Falco, A.B. Grisolia, L.H.C. Andrade, S.M. Lima, G. Machado, V.A. Nascimento, D.A. Gonçalves, H. Wender, S.L. Oliveira, and A.R.L. Caires: Cytotoxic and genotoxic effects of silver nanoparticles on meristematic cells of Allium cepa roots: A close analysis of particle size dependence. Sci. Total Environ. 660, 459 (2019).

D. Surendran, R.S. Sarath Kumar, C.S. Geetha, and P.V. Mohanan: Long term effect of biodegradable polymer on oxidative. BIO 2, 37 (2012).

M.C. Echave, P. Sánchez, J.L. Pedraz, and G. Orive: Progress of gelatin-based 3D approaches for bone regeneration. J. Drug Deliv. Sci. Technol. 42, 63 (2017).

I. Silva de Sá, A.P. Peron, F.V. Leimann, G.N. Bressan, B.N. Krum, R. Fachinetto, J. Pinela, R.C. Calhelha, M.F. Barreiro, I.C.F.R. Ferreira, O.H. Gonçalves, and R.P. Ineu: In vitro and in vivo evaluation of enzymatic and antioxidant activity, cytotoxicity, and genotoxicity of curcumin-loaded solid dispersions. Food Chem. Toxicol. 125, 29 (2019).

G.K. Srivastava, M.L. Alonso-Alonso, I. Fernandez-Bueno, M.T. Garcia-Gutierrez, F. Rull, J. Medina, R.M. Coco, and J.C. Pastor: Comparison between direct contact and extract exposure methods for PFO cytotoxicity evaluation. Sci. Rep. 8, 1 (2018).

V.J. Sunandhakumari, A.K. Vidhyadharan, A. Alim, D. Kumar, J. Ravindran, A. Krishna, and M. Prasad: Fabrication and in vitro characterization of bioactive glass/nano hydroxyapatite reinforced electrospun poly(ε-caprolactone) composite membranes for guided tissue regeneration. Bioengineering 5, 54 (2018).

P. Morouço, S. Biscaia, T. Viana, M. Franco, C. Malça, A. Mateus, C. Moura, F.C. Ferreira, G. Mitchell, and N.M. Alves: Fabrication of poly(ε-caprolactone) scaffolds reinforced with cellulose nanofibers, with and without the addition of hydroxyapatite nanoparticles. BioMed Res. Int. 2016, 1–10 (2016).

International Organization for Standardization. ISO 10993-5. In: Biological Evaluation of Medical Devices-Part 5: Tests for In Vitro Cytotoxicity. Geneve: ISO; 2009.

S.M. Davachi, B. Shiroud Heidari, I. Hejazi, J. Seyfi, E. Oliaei, A. Farzaneh, and H. Rashedi: Interface modified polylactic acid/starch/poly ε-caprolactone antibacterial nanocomposite blends for medical applications. Carbohydr. Polym. 155, 336 (2017).

M. Ghadiri, W. Chrzanowski, W.H. Lee, A. Fathi, F. Dehghani, and R. Rohanizadeh: Physico-chemical, mechanical, and cytotoxicity characterizations of laponite®/alginate nanocomposite. Appl. Clay Sci. 85, 64 (2013).

A.J. Mieszawska, N. Fourligas, I. Georgakoudi, N.M. Ouhib, D.J. Belton, C.C. Perry, and D.L. Kaplan: Osteoinductive silk-silica composite biomaterials for bone regeneration. Biomaterials 31, 8902 (2010).

M.C. Barbosa, N.R. Messmer, T.R. Brazil, F.R. Marciano, and A.O. Lobo: The effect of ultrasonic irradiation on the crystallinity of nano-hydroxyapatite produced via the wet chemical method. Mater. Sci. Eng. C 33, 2620 (2013).

G. Fiskesjö: The allium test as a standard in environmental monitoring. Hereditas 102, 99 (1985).

Acknowledgments

This research was funded by the Brazilian National Council for Scientific and Technological Development (CNPq AOL Nos. 303752/2017-3 and 404683/2018-5) FCO acknowledgment Universidade Estacio bolsa de produtividade do programa de pesquisa e produtividade.

Author information

Authors and Affiliations

Corresponding authors

Additional information

3

These authors contributed equally to this work.

Supplementary Material

Rights and permissions

About this article

Cite this article

de Araujo, F.P., Batista, I.T.S., de Oliveira, F.C. et al. Printing composite nanofilaments for use in a simple and low-cost 3D pen. Journal of Materials Research 35, 1154–1162 (2020). https://doi.org/10.1557/jmr.2020.77

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.77