Abstract

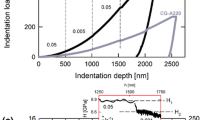

With the ever-increasing importance of nanoscale deformation phenomena in contemporary technologies, basic understanding of material behavior at the nanoscale has become of critical importance. Especially, nanomechanical testing that provides the capability to study fundamental nanoscale deformation and phase change phenomena in real time and under controlled loading conditions is essential for nanomaterial research. In this study, acoustic emission (AE) was used in situ to characterize nanoindentation-induced deformation, microfracture, and phase transformation processes intrinsic of bulk single-crystal MgO and polycrystalline Al, thin films of polycrystalline SiC, and thick films of austenitic TiNi shape-memory alloy. Scale-dependent plastic deformation and microfracture affected by the indenter tip radius and the applied normal load are interpreted in terms of the type and intensity of AE events revealed by abrupt displacement excursions in the loading response of the indented materials. The amplitudes of AE waveforms are used to examine characteristic deformation, microfracture, and phase change mechanisms in the time domain. Fast Fourier transformation and short-time Fourier transformation analyses provide further insight into the material behavior and structural changes due to indentation loading in the frequency and time-frequency domain, respectively. The methodology developed in this study represents an effective approach for nanomechanical testing and in situ characterization of nanoscale deformation, microfracture, and phase transformation phenomena.

Similar content being viewed by others

References

Y-T. Cheng, T. Page, G.M. Pharr, M.V. Swain, and K.J. Wahl: Fundamentals and applications of instrumented indentation in multidisciplinary research. J. Mater. Res. 19, 1 (2004).

T.F. Page, W.C. Oliver, and C.J. McHargue: The deformation behavior of ceramic crystals subjected to very low load (nano)indentations. J. Mater. Res. 7, 450 (1992).

C. Tromas, J.C. Girard, V. Audurier, and J. Woirgard: Study of the low stress plasticity in single-crystal MgO nanoindentation and atomic force microscopy. J. Mater. Sci. 34, 5337 (1999).

A. Kailer, Y.G. Gogotsi, and K.G. Nickel: Phase transformations of silicon caused by contact loading. J. Appl. Phys. 81, 3057 (1997).

R.A. Fleming and M. Zou: The effects of confined core volume on the mechanical behavior of Al/a-Si core–shell nanostructures. Acta Mater. 128, 149 (2017).

J.S. Field, M.V. Swain, and R.D. Dukino: Determination of fracture toughness from the extra penetration produced by indentation-induced pop-in. J. Mater. Res. 18, 1412 (2003).

E.G. Berasategui and T.F. Page: The contact response of thin SiC-coated silicon systems—Characterisation by nanoindentation. Surf. Coat. Technol. 163–164, 491 (2003).

J. Zhou, K. Komvopoulos, and A.M. Minor: Nanoscale plastic deformation and fracture of polymers studied by in situ nanoindentation in a transmission electron microscope. Appl. Phys. Lett. 88, 181908 (2006).

P. Dyjak and R.P. Singh: Acoustic emission analysis of nanoindentation-induced fracture events. Exp. Mech. 46, 333 (2006).

V. Domnich, Y. Gogotsi, and S. Dub: Effect of phase transformations on the shape of the unloading curve in the nanoindentation of silicon. Appl. Phys. Lett. 76, 2214 (2000).

G. Behrens, G.W. Dransmann, and A.H. Heuer: On the isothermal martensitic transformation in 3Y-TZP. J. Am. Ceram. Soc. 76, 1025 (1993).

A. Kailer, K.G. Nickel, and Y.G. Gogotsi: Raman microspectroscopy of nanocrystalline and amorphous phases in hardness indentations. J. Raman Spectrosc. 30, 939 (1999).

X-G. Ma and K. Komvopoulos: Nanoscale pseudoelastic behavior of indented titanium-nickel films. Appl. Phys. Lett. 84, 3773 (2003).

Z.C. Li, L. Liu, X. Wu, L.L. He, and Y.B. Xu: Indentation induced amorphization in gallium arsenide. Mater. Sci. Eng. A 337, 21 (2002).

B-G. Yoo, I-C. Choi, Y-J. Kim, J-Y. Suh, U. Ramamurty, and J-i. Jang: Further evidence for room temperature, indentation-induced nanocrystallization in a bulk metallic glass. Mater. Sci. Eng. A 545, 225 (2012).

J-J. Kim, Y. Choi, S. Suresh, and A.S. Argon: Nanocrystallization during nanoindentation of a bulk amorphous metal alloy at room temperature. Science 295, 654 (2002).

A.M. Minor, J.W. Morris, Jr., and E.A. Stach: Quantitative in situ nanoindentation in an electron microscope. Appl. Phys. Lett. 79, 1625 (2001).

K. Komvopoulos and X-G. Ma: Pseudoelasticity of martensitic titanium-nickel shape-memory films studied by in situ heating nanoindentation and transmission electron microscopy. Appl. Phys. Lett. 87, 263108 (2005).

J.M. Carlyle: In-flight crack detection via acoustic emission. J. Acoust. Soc. Am. 68, S104 (1980).

R.M. Koerner and A.E. Lord, Jr.: Application of acoustic emission in the geotechnical area. J. Acoust. Soc. Am. 64, S175 (1978).

R.S. McWilliams, D.K. Spaulding, J.H. Eggert, P.M. Celliers, D.G. Hicks, R.F. Smith, G.W. Collins, and R. Jeanloz: Phase transformations and metallization of magnesium oxide at high pressure and temperature. Science 338, 1330 (2012).

A.R. Oganov, M.J. Gillan, and G.D. Price: Ab initio lattice dynamics and structural stability of MgO. J. Chem. Phys. 118, 10174 (2003).

D. Alfè, M. Alfredsson, J. Brodholt, M.J. Gillan, M.D. Towler, and R.J. Needs: Quantum Monte Carlo calculations of the structural properties and the B1–B2 phase transition of MgO. Phys. Rev. B 72, 014114 (2005).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, U.K., 1985).

N.I. Tymiak, A. Daugela, T.J. Wyrobek, and O.L. Warren: Highly localized acoustic emission monitoring of nanoscale indentation contacts. J. Mater. Res. 18, 784 (2003).

S.G. Corcoran, R.J. Colton, E.T. Lilleodden, and W.W. Gerberich: Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 55, R16057 (1997).

D.F. Bahr, D.E. Kramer, and W.W. Gerberich: Non-linear deformation mechanisms during nanoindentation. Acta Mater. 46, 3605 (1998).

E.A. Stach, T. Freeman, A.M. Minor, D.K. Owen, J. Cumings, M.A. Wall, T. Chraska, R. Hull, J.W. Morris, Jr., A. Zettl, and U. Dahmen: Development of a nanoindenter for in situ transmission electron microscopy. Microsc. Microanal. 7, 507 (2001).

M. Shiwa, E.R. Weppelmann, A. Bendeli, M.V. Swain, D. Munz, and T. Kishi: Acoustic emission and precision force-displacement observations of spherical indentations into TiN films on silicon. Surf. Coat. Technol. 68–69, 598 (1994).

X-G. Ma, K. Komvopoulos, and D.B. Bogy: Nanoindentation of polycrystalline silicon–carbide thin films studied by acoustic emission. Appl. Phys. Lett. 85, 1695 (2004).

K. Sangwal, P. Gorostiza, J. Servat, and F. Sanz: Atomic force microscopy study of nanoindentation deformation and indentation size effect in MgO crystals. J. Mater. Res. 14, 3973 (1999).

C.R. Stoldt, M.C. Fritz, C. Carraro, and R. Maboudian: Micromechanical properties of silicon-carbide thin films deposited using single-source chemical-vapor deposition. Appl. Phys. Lett. 79, 347 (2001).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

X-G. Ma and K. Komvopoulos: Pseudoelasticity of shape-memory titanium–nickel films subjected to dynamic nanoindentation. Appl. Phys. Lett. 84, 4274 (2004).

X-G. Ma and K. Komvopoulos: In situ transmission electron microscopy and nanoindentation studies of phase transformation and pseudoelasticity of shape-memory titanium–nickel films. J. Mater. Res. 20, 1808 (2005).

H-S. Zhang and K. Komvopoulos: Nanoscale pseudoelasticity of single-crystal Cu–Al–Ni shape-memory alloy induced by cyclic nanoindentation. J. Mater. Sci. 41, 5021 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, XG., Komvopoulos, K. Nanoindentation-induced deformation, microfracture, and phase transformation in crystalline materials investigated in situ by acoustic emission. Journal of Materials Research 35, 380–390 (2020). https://doi.org/10.1557/jmr.2020.5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.5