Abstract

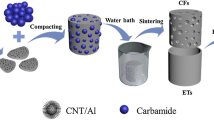

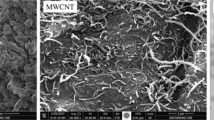

In this paper, CNTs reinforced foam aluminum matrix composites with small pore diameter were prepared by powder metallurgy method. When the mass fraction of CNTs was 0.75%, the tensile strength, flexural strength and compressive yield strength of the materials were 3.4 times, 2.4 times and 2.4 times of pure foam aluminum, respectively, reaching the maximum value, which obviously improved the mechanical properties of aluminum foam. The tensile property model of foam aluminum matrix composites was built to predict the properties of the composites, and the effects of defects and reinforcement on the mechanical properties of the composites were compared. The results show that the tensile fitting is consistent with the measured results when the mass fraction of CNTs is less than 0.75%, but the weakening effect of defects on the strength of aluminum foam is much greater than the enhancement of CNTs. With the increase of CNTs mass fraction, the damping loss factor of foam aluminum composites increases, dislocation damping and grain boundary damping play a role in advance, and the damping peak moves to the low temperature region.

Similar content being viewed by others

References

D.H. Yang and D.P. He: Porosity of porous Al alloys. Sci. China: Chem. 44(4), 411–418 (2001).

G.C. Yao, H.J. Luo and Z.K. Cao: The properties and application technology of the aluminum foam material. In International Conference on Advanced Material Engineering, 2015, pp. 442–450.

Y. Du, A.B. Li, X.X. Zhang, Z.B. Tan, R.Z. Su, F. Pu and L. Geng: Enhancement of the mechanical strength of aluminum foams by SiC nanoparticles. Mater. Lett. 148, 79–81 (2015).

A. Daoud: Compressive response and energy absorption of foamed A359 -Al2O3 particle composites. J. Alloys Compd. 486(1-2), 597–605 (2009).

A. Krishnan, E. Dujardin, T.W. Ebbesen and P.N. Yianilos: Young's modulus of single-walled nanotubes. Phys. Rev. B 58(20), 14013–14019 (1998).

I. Duartea, E. Ventura, S. Olhero and J.M. Ferreira: An effective approach to reinforced closed-cell Al-alloy foams with multiwalled carbon nanotubes. Carbon 95, 589–600 (2015).

Z. Zhang, J. Ding, X.C. Xia, X.H. Sun, K.H. Song, W.M. Zhao, B. Liao: Fabrication and characterization of closed-cell aluminum foams with different contents of multi-walled carbon nanotubes. Mater. Des. 88, 359–365 (2015).

K.M. Yang, X.D. Yang, E.Z. Liu, C.S. Shi, L.Y. Ma, C.N. He, Q.Y. Li, J.J. Li and N.Q. Zhao: Elevated temperature compressive properties and energy absorption response of in-situ grown CNT-reinforced Al composite foams. Mater. Sci. Eng. 690, 294–302 (2017).

B. Jiang, Z.J. Wang and N.Q. Zhao: Effect of pore size and relative density on the mechanical properties of open cell aluminum foams. Scr. Mater. 56(2), 169–172 (2007).

N.Q. Zhao, W.X. Zhao, B. Jiang, D.H. Fu and F.G. Zhou: Damping properties of aluminum foams produced by pressing-dissolution-vacuum sintering process. Powder Metall. Techol. 24(2), 127–130 (2006).

Y.Z. Li, X.F. Wang, X.F. Wang, Y.L. Ren, F.S. Han and C. Wen: Sound absorption characteristics of aluminum foam with spherical cells. J. Appl. Phys. 110(11), 113525 (2011).

H.J. Choi, J.H. Shin and D.H. Bae: Grain size effect on the strengthening behavior of aluminum-based composites containing multi-walled carbon nanotubes. Compos. Sci. Technol. 71(15), 1699–1705 (2011).

H. Arami and A. Simchi: Reactive milling synthesis of nanocrystalline Al -Cu/Al2O3 nanocomposite. Mater. Sci. Eng. A 464 (1), 225–232 (2007).

B. Chen, S.F. Li, H. Imai, L. Jia, J. Umeda, M. Takahashi: Load transfer strengthening in carbon nanotubes reinforced metal matrix composites via in-situ tensile tests. Compos. Sci. Technol. 113, 1–8 (2015).

H. Kurita, M. Estili, H. Kwon, T. Miyazaki, W.W. Zhou, J. Silvain and A. Kawasaki: Load-bearing contribution of multi-walled carbon nanotubes on tensile response of aluminum. Compos. Part A Appl. Sci. 68, 133–139 (2015).

H. Kwon, D.H. Park, J.F. Silvain and A. Kawasaki: Investigation of carbon nanotube reinforced aluminum matrix composite materials. Compos. Sci. Technol. 70(3), 546–550 (2010).

S.E. Shin and D.H. Bae: Strengthening behavior of chopped multi-walled carbon nanotube reinforced aluminum matrix composites. Mater. Charact. 83, 170–177 (2013).

A. Granato and K. Lücke: Theory of mechanical damping due to dislocations. J. Appl. Phys. 27(6), 583–593 (2004).

T. Kê: A grain boundary model and the mechanism of viscous intercrystalline slip. J. Appl. Phys. 20(3), 274–280 (1949).

J. Zhang, M.N. Gungor, and E.J. Lavernia: The effect of porosity on the microstructural damping response of 6061 aluminium alloy. J. Mater. Sci. 28(6), 1515–1524 (1993).

T.S. Srivatsan, I.A. Ibrahim, F.A. Mohamed and E.J. Lavernia: Processing techniques for particulate-reinforced metal aluminium matrix composites. J. Mater. Sci. 26(22), 5965–5978 (1991).

F.S. Han, Z.G. Zhu, C.S. Liu and J.C. Gao: Damping behavior of foamed aluminum. Metall. Mater. Trans. A 30(3), 771–776 (1999).

S.U. Khan, C.Y. Li, N.A. Siddiqui and J.K. Kim: Vibration damping characteristics of carbon fiber-reinforced composites containing multi-walled carbon nanotubes. Compos. Sci. Technol. 71(12), 1486–1494 (2011).

X. Zhou, E. Shin, K.W. Wang and C.E. Bakis: Interfacial damping characteristics of carbon nanotube-based composites. Compos. Sci. Technol. 64(15), 2425–2437 (2004).

C.F. Deng, D.Z. Wang, X.X. Zhangan and Y.X. Ma: Damping characteristics of carbon nanotube reinforced aluminum composite. Mater. Lett. 61(14 -15), 3229–3231 (2007).

S. Guo, R. Sivakumar and Y. Kagawa: Multiwall carbon nanotube-SiO2 nanocomposites: Sintering, elastic properties, and fracture toughness. Adv. Eng. Mater. 9(1 -2), 84–87 (2007).

A. Peigney, E. Flahaut, C. Laurent, F. Chastel and A. Rousset: Aligned carbon nanotubes in ceramic-matrix nanocomposites prepared by high-temperature extrusion. Chem. Phys. Lett. 352(1-2), 20–25 (2002).

Q. Huang and L. Gao: Multiwalled carbon nanotube/BaTiO3 nanocomposites: Electrical and rectification properties. Appl. Phys. Lett. 86(12), 631 (2005).

M.F. Ashby, R.F.M. Medalist: The mechanical properties of cellular solids. Metall. Mater. Trans. A 14(9), 1755–1769 (1983).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, M., Liu, B., Ji, Z. et al. Mechanical properties and damping properties of carbon nanotube-reinforced foam aluminum with small aperture. Journal of Materials Research 35, 2567–2574 (2020). https://doi.org/10.1557/jmr.2020.135

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.135