Abstract

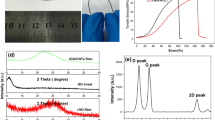

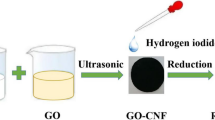

Graphene-based flexible and wearable supercapacitors have been produced by wet spinning, in which organic solvent coagulating bath was prerequisite and spacers were usually incorporated to improve the electrochemical property but sacrificing the mechanical property. In this work, a nonorganic solvent spinning technology named as interfacial polyelectrolyte complexation (IPC), which was based on the spontaneous self-assembly of two oppositely charged polyelectrolyte solutions/suspensions to form continuous fibers on drawing in their interfaces, was proposed to fabricate graphene fiber–shaped electrodes for supercapacitors. Due to the excellent mechanical performance and hydrophilicity, cellulose nanofibrils (CNFs) were added to serve as an efficient reinforcing agent and spacer of graphene fiber electrodes. Consequently, the mechanical performance and specific capacitance of the fibers were improved but electrical conductivity was declined. Taking overall consideration, CNF/rGO60 fiber electrode possessed a superior integrated performance with a capacitance of 182.6 F/g, tensile strength of 480 MPa, and electrical conductivity of 5538.7 S/m. The IPC spinning provided an environmentally friendly strategy for the fabrication of fiber-shaped functional devices.

Similar content being viewed by others

References

H. Minjeong, P. Jonghwa, L. Youngoh, and K. Hyunhyub: Triboelectric generators and sensors for self-powered wearable electronics. ACS Nano 9, 4 (2015).

Z. Wei, S. Lin, L. Qiao, C. Song, W. Fei, and T. Xiao-Ming: Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 26, 31 (2014).

X. Cai, M. Peng, X. Yu, Y. Fu, and D. Zou: Flexible planar/fiber-architectured supercapacitors for wearable energy storage. J. Mater. Chem. C 2, 7 (2014).

Y. Shao, M.F. El-Kady, L.J. Wang, Q. Zhang, Y. Li, H. Wang, M.F. Mousavi, and R.B. Kaner: Graphene-based materials for flexible supercapacitors. ChemInform 46, 30 (2015).

D. Yu, K. Goh, H. Wang, L. Wei, W. Jiang, Q. Zhang, L. Dai, and Y. Chen: Scalable synthesis of hierarchically structured carbon nanotube-graphene fibres for capacitive energy storage. Nat. Nanotechnol. 9, 7 (2014).

D. Yu, S. Zhai, W. Jiang, K. Goh, L. Wei, X. Chen, R. Jiang, and Y. Chen: Transforming pristine carbon fiber tows into high performance solid-state fiber supercapacitors. Adv. Mater. 27, 33 (2015).

W. Guoping, Z. Lei, and Z. Jiujun: A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 41, 2 (2012).

A. Ramadoss, K.Y. Yoon, M.J. Kwak, S.I. Kim, S.T. Ryu, and J.H. Jang: Fully flexible, lightweight, high performance all-solid-state supercapacitor based on 3-dimensional-graphene/graphite-paper. J. Power Sources 337, 159 (2017).

M.A. Sakka, H. Gualous, and J.V. Mierlo: Characterization of supercapacitors matrix. Electrochim. Acta 55, 25 (2010).

P. Simon and Y. Gogotsi: Materials for electrochemical capacitors. Nat. Mater. 7, 11 (2008).

J. Yan, W. Qian, W. Tong, and Z. Fan: Supercapacitors: Recent advances in design and fabrication of electrochemical supercapacitors with high energy densities. Adv. Energy Mater. 4, 4 (2014).

M. Vangari, T. Pryor, and L. Jiang: Supercapacitors: Review of materials and fabrication methods. J. Energy Eng. 139, 2 (2013).

E. Raymundo-Piñero, F. Leroux, and F. Béguin: A high-performance carbon for supercapacitors obtained by carbonization of a seaweed biopolymer. Adv. Mater. 18, 14 (2010).

K. Wang, Q. Meng, Y. Zhang, Z. Wei, and M. Miao: High-performance two-ply yarn supercapacitors based on carbon nanotubes and polyaniline nanowire arrays. Adv. Mater. 25, 10 (2013).

H. Yue, C. Huhu, Z. Fei, C. Nan, J. Lan, F. Zhihai, and Q. Liangti: All-in-one graphene fiber supercapacitor. Nanoscale 6, 12 (2014).

M. Yuning, Z. Yang, H. Chuangang, C. Huhu, H. Yue, Z. Zhipan, S. Gaoquan, and Q. Liangti: All-graphene core-sheath microfibers for all-solid-state, stretchable fibriform supercapacitors and wearable electronic textiles. Adv. Mater. 25, 16 (2013).

M. Pumera: Graphene-based nanomaterials for energy storage. Energy Environ. Sci. 4, 3 (2011).

M.D. Stoller, S. Park, Y. Zhu, J. An, and R.S. Ruoff: Graphene-based ultracapacitors. Nano Lett. 8, 10 (2008).

X. Yang and D. Li: Electrolyte-mediated dense integration of graphene materials for compact capacitive energy storage. Science 341, 6145 (2013).

Z. Xu and C. Gao: Graphene chiral liquid crystals and macroscopic assembled fibres. Nat. Commun. 2, 1 (2011).

T. Huang, B. Zheng, L. Kou, K. Gopalsamy, Z. Xu, C. Gao, Y. Meng, and Z. Wei: Flexible high performance wet-spun graphene fiber supercapacitors. RSC Adv. 3, 46 (2013).

T. Huang, B. Zheng, Z. Liu, L. Kou, and C. Gao: High rate capability supercapacitors assembled from wet-spun graphene films with a CaCO3 template. J. Mater. Chem. A 3, 5 (2015).

Z. Li, T. Huang, W. Gao, Z. Xu, D. Chang, C. Zhang, and C. Gao: Hydrothermally activated graphene fiber fabrics for textile electrodes of supercapacitors. ACS Nano 11, 11 (2017).

H. Tieqi, C. Xingyuan, C. Shengying, Y. Qiuyan, C. Hao, L. Yingjun, G. Karthikeyan, X. Zhen, G. Weiwei, and G. Chao: Tri-high designed graphene electrodes for long cycle-life supercapacitors with high mass loading. Energy Storage Mater. 17, 349 (2019).

Z. Dong, C. Jiang, H. Cheng, Y. Zhao, G. Shi, L. Jiang, and L. Qu: Facile fabrication of light, flexible and multifunctional graphene fibers. Adv. Mater. 24, 14 (2012).

Z. Xu, H. Sun, X. Zhao, and C. Gao: Ultrastrong fibers assembled from giant graphene oxide sheets. Adv. Mater. 25, 2 (2013).

S. Chen, W. Ma, Y. Cheng, Z. Weng, B. Sun, L. Wang, W. Chen, F. Li, M. Zhu, and H.M. Cheng: Scalable non-liquid-crystal spinning of locally aligned graphene fibers for high-performance wearable supercapacitors. Nano Energy 15, 642 (2015).

Y. Yu, Y. Sun, C. Cao, S. Yang, H. Liu, P. Li, P. Huang, and W. Song: Graphene-based composite supercapacitor electrodes with diethylene glycol as inter-layer spacer. J. Mater. Chem. A 2, 21 (2014).

L. Kou, T. Huang, B. Zheng, Y. Han, X. Zhao, K. Gopalsamy, H. Sun, and C. Gao: Coaxial wet-spun yarn supercapacitors for high-energy density and safe wearable electronics. Nat. Commun. 5, 5 (2014).

G. Sun, J. Liu, X. Zhang, X. Wang, H. Li, Y. Yu, W. Huang, H. Zhang, and P. Chen: Fabrication of ultralong hybrid microfibers from nanosheets of reduced graphene oxide and transition-metal dichalcogenides and their application as supercapacitors. Angew. Chem. 53, 46 (2015).

Q. Cheng, J. Tang, J. Ma, H. Zhang, N. Shinya, and L.C. Qin: Graphene and nanostructured MnO composite electrodes for supercapacitors. Carbon 49, 9 (2011).

G. Yu, L. Hu, M. Vosgueritchian, H. Wang, X. Xie, J.R. Mcdonough, X. Cui, Y. Cui, and Z. Bao: Solution-processed graphene/MnO2 nanostructured textiles for high-performance electrochemical capacitors. Nano Lett. 11, 7 (2011).

G. Chen, T. Chen, K. Hou, W. Ma, M. Tebyetekerwa, Y. Cheng, W. Weng, and M. Zhu: Robust, hydrophilic graphene/cellulose nanocrystal fiber-based electrode with high capacitive performance and conductivity. Carbon 127, 218 (2018).

G. Xin, W. Zhu, Y. Deng, J. Cheng, L.T. Zhang, A.J. Chung, S. De, and J. Lian: Microfluidics-enabled orientation and microstructure control of macroscopic graphene fibres. Nat. Nanotechnol. 14, 2 (2019).

X. Zhen, S. Haiyan, Z. Xiaoli, and G. Chao: Ultrastrong fibers assembled from giant graphene oxide sheets. Adv. Mater. 25, 2 (2013).

Z. Xu, Y. Liu, X. Zhao, L. Peng, H. Sun, Y. Xu, X. Ren, C. Jin, P. Xu, and M. Wang: Ultrastiff and strong graphene fibers via full-scale synergetic defect engineering. Adv. Mater. 28, 30 (2016).

R. Jalili, S.H. Aboutalebi, D. Esrafilzadeh, R.L. Shepherd, J. Chen, S. Aminorroaya-Yamini, K. Konstantinov, A.I. Minett, J.M. Razal, and G.G. Wallace: Graphene oxide: Scalable one-step wet-spinning of graphene fibers and yarns from liquid crystalline dispersions of graphene oxide: Towards multifunctional textiles. Adv. Funct. Mater. 23, 43 (2013).

Y. Zhang, J. Peng, M. Li, E. Saiz, S.E. Wolf, and Q. Cheng: Bioinspired supertough graphene fiber through sequential interfacial interactions. ACS Nano 12, 9 (2018).

K. Zhang and H. Liimatainen: Hierarchical assembly of nanocellulose-based filaments by interfacial complexation. Small 14, 38 (2018).

M.S. Toivonen, S. Kurkisuonio, W. Wagermaier, V. Hynninen, S. Hietala, and O. Ikkala: Interfacial polyelectrolyte complex spinning of cellulose nanofibrils for advanced bicomponent fibers. Biomacromolecules 18, 4 (2017).

O. Nechyporchuk, R. Bordes, and T. Köhnke: Wet spinning of flame-retardant cellulosic fibers supported by interfacial complexation of cellulose nanofibrils with silica nanoparticles. ACS Appl. Mater. Interfaces 9, 44 (2017).

R. Grande, E. Trovatti, A.J. Carvalho, and A. Gandini: Continuous microfiber drawing by interfacial charge complexation between anionic cellulose nanofibers and cationic chitosan. J. Mater. Chem. A 5, 25 (2017).

M. Amaike, Y. Senoo, and H. Yamamoto: Sphere, honeycomb, regularly spaced droplet and fiber structures of polyion complexes of chitosan and gellan. Macromol. Rapid Commun. 19, 6 (1998).

C. Clemons: Nanocellulose in spun continuous fibers: A review and future outlook. J. Renewable Mater. 4, 5 (2016).

A.C. Wan, M.F. Cutiongco, B.C. Tai, M.F. Leong, H.F. Lu, and E.K. Yim: Fibers by interfacial polyelectrolyte complexation–processes, materials and applications. Mater. Today 19, 8 (2016).

A.J. Granero, J.M. Razal, G.G. Wallace, and M. in het Panhuis: Mechanical reinforcement of continuous flow spun polyelectrolyte complex fibers. Macromol. Biosci. 9, 4 (2010).

A.J. Granero, J.M. Razal, G.G. Wallace, and M.I.H. Panhuis: Cover picture: Spinning carbon nanotube-gel fibers using polyelectrolyte complexation (adv. Funct. Mater. 23/2008). Adv. Funct. Mater. 18, 23 (2008).

F.L. Meng, J.K.C. Toh, D. Chan, K. Narayanan, F.L. Hong, T.C. Lim, A.C.A. Wan, and J.Y. Ying: Patterned prevascularised tissue constructs by assembly of polyelectrolyte hydrogel fibres. Nat. Commun. 4, 4 (2013).

K. Ohkawa, Y. Takahashi, M. Yamada, and H. Yamamoto: Polyion complex fiber and capsule formed by self-assembly of chitosan and poly(α,l-glutamic acid) at solution interfaces. Macromol. Mater. Eng. 286, 3 (2015).

A.C. Wan, E.K. Yim, I.C. Liao, V.C. Le, and K.W. Leong: Encapsulation of biologics in self-assembled fibers as biostructural units for tissue engineering. J. Biomed. Mater. Res., Part A 71, 4 (2004).

A.C.A. Wan, F.L. Meng, J.K.C. Toh, Y. Zheng, and J.Y. Ying: Multicomponent fibers by multi-interfacial polyelectrolyte complexation. Adv. Healthcare Mater. 1, 1 (2012).

J.P. Reddy and J.W. Rhim: Extraction and characterization of cellulose microfibers from agricultural wastes of onion and garlic. J. Nat. Fibers 15, 4 (2018).

L. Geng, B. Chen, X. Peng, and T. Kuang: Strength and modulus improvement of wet-spun cellulose I filaments by sequential physical and chemical cross-linking. Mater. Des. 136, 45 (2017).

Y. Mao, K. Liu, C. Zhan, L. Geng, B. Chu, and B.S. Hsiao: Characterization of nanocellulose using small-angle neutron, X-ray, and dynamic light scattering techniques. J. Phys. Chem. B 121, 6 (2017).

L. Geng, X. Peng, C. Zhan, A. Naderi, P.R. Sharma, Y. Mao, and B.S. Hsiao: Structure characterization of cellulose nanofiber hydrogel as functions of concentration and ionic strength. Cellulose 24, 12 (2017).

V. Zargar, M. Asghari, and A. Dashti: A review on chitin and chitosan polymers: Structure, chemistry, solubility, derivatives, and applications. ChemBioEng Rev. 2, 3 (2015).

C.K.S. Pillai, W. Paul, and C.P. Sharma: Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 34, 7 (2009).

C. Yao, Z. Xiong, D. Zhang, Y. Peng, and Y. Ma: High performance supercapacitors based on reduced graphene oxide in aqueous and ionic liquid electrolytes. Carbon 49, 2 (2011).

Acknowledgments

This work was supported by Scientific Research Foundation of Fujian University of Technology (E0600339), Development fund of Fujian University of Technology (E0100589), and National Nature Science Foundation of China (No.51503069).

Author information

Authors and Affiliations

Corresponding authors

Supplementary Material

43578_2020_35020122_MOESM1_ESM.docx

Supporting Information: Fiber-shape Electrodes Based on Graphene/Cellulose Nanofibrils by Interfacial Polyelectrolyte Complexation Spinning, approximately 336 KB

Rights and permissions

About this article

Cite this article

Lin, Y., Wen, S., Peng, X. et al. Interfacial polyelectrolyte complexation spinning of graphene/cellulose nanofibrils for fiber-shaped electrodes. Journal of Materials Research 35, 122–131 (2020). https://doi.org/10.1557/jmr.2019.390

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.390