Abstract

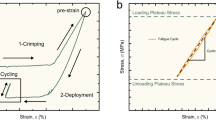

Fatigue of superelastic Nitinol in the mixed austenite–martensite state was examined in tension using center-tapered dog-bone specimens. A prestraining procedure, mimicking the load history of a medical device component, was applied prior to cycling: specimens were loaded to a fully martensitic state, unloaded partway into the lower plateau to a mixed-phase state, and then subjected to sinusoidal displacement cycles. Strain maps, obtained using digital image correlation, showed substantial variation in local mean and alternating strains across the gage section. In situ surface imaging using a high-speed camera confirmed crack initiation in a narrow transition zone between austenite and martensite that undergoes cyclic stress-induced martensitic transformation (SIMT). Fatigue life data showed an abrupt transition from high-cycle runouts to low-cycle fatigue failures at a stress amplitude level corresponding to the threshold for activating cyclic SIMT. The fatigue threshold can be estimated from the tensile loading–unloading curve.

Similar content being viewed by others

References

A.L. McKelvey and R.O. Ritchie: Fatigue-crack growth in the superelastic endovascular stent material nitinol. In Biomedical Materials-Drug Delivery, Implants and Tissue Engineering, Vol. 550, T. Neenan, M. Marcolongo, and R.F. Valentini, eds. (Mater. Res. Soc. Symp. Proc., Pittsburgh, PA, 1999); p. 281.

S.W. Robertson, A.R. Pelton, and R.O. Ritchie: Mechanical fatigue and fracture of Nitinol. Int. Mater. Rev. 57, 1 (2012).

K.N. Melton and O. Mercier: Fatigue of NiTi thermoelastic martensites. Acta Metall. 27, 137 (1979).

S. Miyazaki, Y. Sugaya, and K. Otsuka: Effects of various factors on fatigue life of Ti–Ni alloys. Proc. MRS Int. Meet. Adv. Mater. 9, 251 (1988).

Y.S. Kim and S. Miyazaki: Fatigue properties of Ti–50.9 at.% Ni shape memory wires. In Proceedings of SMST-97 (Int. Org. on SMST, Pacific Grove, CA, 1997); p. 473.

Y. Kim: Fatigue properties of the Ti–Ni base shape memory alloy wire. Mater. Trans. 43, 1703 (2002).

G. Eggeler, E. Hornbogen, A. Yawny, A. Heckmann, and M. Wagner: Structural and functional fatigue of NiTi shape memory alloys. Mater. Sci. Eng., A 378, 24 (2004).

M. Wagner, T. Sawaguchi, G. Kausträter, D. Höffken, and G. Eggeler: Structural fatigue of pseudoelastic NiTi shape memory wires. Mater. Sci. Eng., A 378, 105 (2004).

C. Bewerse, K.R. Gall, G.J. McFarland, P. Zhu, and L.C. Brinson: Local and global strains and strain ratios in shape memory alloys using digital imagecorrelation. Mater. Sci. Eng., A 568, 134 (2013).

L. Zheng, Y. He, and Z. Moumni: Investigation on fatigue behaviors of NiTi polycrystalline strips under stress-controlled tension via in situ macro-band observation. Int. J. Plast. 90, 116 (2017).

A.L. McKelvey and R.O. Ritchie: Fatigue-crack growth behavior in the superelastic and shape-memory alloy nitinol. Metall. Mater. Trans. A 32, 731 (2001).

S.W. Robertson, A. Mehta, A.R. Peltonand, and R.O. Ritchie: Evolution of crack-tip transformation zones in superelastic nitinol subjected to in situ fatigue: A fracture mechanics and synchrotron X-ray microdiffraction analysis. Acta Mater. 55, 6198 (2007).

S. Daly, A. Miller, G. Ravichandran, and K. Bhattacharya: Experimental investigation of crack initiation in thin sheets of nitinol. Acta Mater. 55, 6322 (2007).

S.W. Robertson and R.O. Ritchie: In vitro fatigue-crack growth and fracture toughness behavior of thin-walled superelastic nitinol tube for endovascular stents: A basis for defining the effect of crack-like defects. Biomaterials 28, 700 (2006).

A.R. Pelton: Nitinol fatigue: A review of microstructures and mechanisms. J. Mater. Eng. Perform. 20, 613 (2011).

S. Miyazaki, K. Mizukoshi, T. Ueki, T. Sakuma, and Y. Liu: Fatigue life of Ti–50 at.% Ni and Ti–40Ni–10Cu (at.%) shape memory alloy wires. Mater. Sci. Eng., A 273–275, 658 (1999).

M. Reinoehl, D. Bradley, R. Bouthot, and J. Proft: The influence of melt practice on final fatigue properties of superelastic NiTi wires. In SMST-2000 Proceedings from the International Conference on Shape Memory and Superelastic Technologies (Int. Org. SMST, Pacific Grove, CA, 2000); p. 397.

J. Sheriff, A.R. Pelton, and L.A. Pruitt: Hydrogen effects on nitinol fatigue. In Proceedings from the International Conference on Shape Memory and Superelastic Technologies (ASM International, 2004); p. 111.

N. Morgan, A. Wick, J. DiCello, and R. Graham: Carbon and oxygen levels in nitinol alloys and the implications for medical device manufacture and durability. In Proceedings from the International Conference on Shape Memory and Superelastic Technologies (ASM International, 2006); p. 821.

T.A. Sawaguchi, G. Kausträter, A. Yawny, M. Wagner, and G. Eggeler: Crack initiation and propagation in 50.9 at.% Ni–Ti pseudoelastic shape memory wires in bending rotation fatigue. Metall. Mater. Trans. A 34, 2847 (2003).

M.F-X. Wagner and G. Eggeler: New aspects of bending rotation fatigue in ultra-fine-grained pseudo-elastic NiTi wires. Int. J. Mater. Res. 97, 1687 (2006).

R.M. Tabanli, N.K. Simha, and B.T. Berg: Mean stress effects on fatigue of NiTi. Mater. Sci. Eng., A 273–275, 644 (1999).

C. Kugler, D. Matson, and K.E. Perry: Non-zero mean fatigue test protocol for NiTi. In Proceedings from the International Conference on Shape Memory and Superelastic Technologies (Int. Org. SMST, Pacific Grove, CA, 2000); p. 409.

A.R. Pelton, V. Schroeder, M.R. Mitchell, X.Y. Gong, M. Barney, and S.W. Robertson: Fatigue and durability of Nitinol stents. J. Mech. Behav. Biomed. Mater. 1, 153 (2008).

S.W. Robertson, M. Launey, O. Shelley, I. Ong, L. Vien, K. Senthilnathan, P. Saffari, S. Schlegel, and A.R. Pelton: A statistical approach to understand the role of inclusions on the fatigue resistance of superelastic Nitinol wire and tubing. J. Mech. Behav. Biomed. Mater. 51, 119 (2015).

J.A. Shaw and S. Kyriakides: Thermomechanical aspects of NiTi. J. Mech. Phys. Solids 43, 1243 (1995).

P.H. Leo, T.W. Shield, and O.P. Bruno: Transient heat transfer effects on the pseudoelastic behavior of shape-memory wires. Acta Metall. Mater. 41, 2477 (1993).

S. Daly, G. Ravichandran, and K. Bhattacharya: Stress-induced martensitic phase transformation in thin sheets of Nitinol. Acta Mater. 55, 3593 (2007).

B. Reedlunn, C.B. Churchill, E.E. Nelson, J.A. Shaw, and S.H. Daly: Tension, compression, and bending of superelastic shape memory alloy tubes. J. Mech. Phys. Solids 63, 506 (2014).

A.R. Pelton, X-Y. Gong, and T.W. Duerig: Fatigue testing of diamond-shaped specimens. In Medical Device Materials: Proceedings from the Materials & Process for Medical Devices Conference 2003, S. Shrivastava, ed. (ASM International, Materials Park, OH, 2004); p. 199.

T. Ungár, J. Frenzel, S. Gollerthan, G. Ribárik, L. Balogh, and G. Eggeler: On the competition between the stress-induced formation of martensite and dislocation plasticity during crack propagation in pseudoelastic NiTi shape memory alloys. J. Mater. Res. 32, 4433 (2017).

T.W. Duerig and K. Bhattacharya: The influence of the R-phase on the superelastic behavior of NiTi. Shape Mem. Superelasticity 1, 153 (2015).

P. Sedmák, J. Pilch, L. Heller, J. Kopeček, J. Wright, P. Sedlák, M. Frostand, and P. Šittner: Grain-resolved analysis of localized deformation in nickel–titanium wire under tensile load. Science 353, 559 (2016).

R.D. James and Z. Zhang: A way to search for multiferroic materials with “unlikely” combinations of physical properties. In Magnetsim and Structure in Functional Matererials, Vol. 79, A. Planes, L. Manosa, and A. Saxena, eds. (Springer Series in Materials Science, Springer, Berlin, Heidelberg, 2005); p. 159.

C. Chluba, W. Ge, R. Lima de Miranda, J. Strobel, L. Kienle, E. Quandt, and M. Wuttig: Ultralow-fatigue shape memory alloy films. Science 348, 1004 (2015).

C. Bonsignore: Present and future approaches to lifetime prediction of superelastic nitinol. Theor. Appl. Fract. Mech. 92, 298 (2017).

A. Shamimi, B. Amin-Ahmadi, A. Stebner, and T. Duerig: The effect of low temperature aging and the evolution of R-phase in Ni-rich NiTi. Shape Mem. Superelasticity 4, 417 (2018).

A. Runciman, D. Xu, A.R. Pelton, and R.O. Ritchie: An equivalent strain/Coffin-Manson approach to multiaxial fatigue and life prediction in superelastic Nitinol medical devices. Biomaterials 32, 4987 (2011).

Acknowledgments

We thank Herwig Mayer and Michael Fitzka at the University of Natural Resources and Life Sciences, Vienna, Austria, for providing the fatigue specimen design for use in this study. We thank James Hallquist for conducting several of the fatigue life tests. We also thank Mallika Kamarajugadda, Richard Francis, Markus Reiterer, Curtis Goreham-Voss, Scott Terry, and Shivram Sridhar at Medtronic plc for their many helpful discussions and comments that significantly improved this manuscript. Sharvan Kumar and Zhiwei Ma acknowledge Medtronic for the research grant to Brown University that enabled this collaborative work.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has been selected as an Invited Feature Paper.

Rights and permissions

About this article

Cite this article

Catoor, D., Ma, Z. & Kumar, S. Cyclic response and fatigue failure of Nitinol under tension–tension loading. Journal of Materials Research 34, 3504–3522 (2019). https://doi.org/10.1557/jmr.2019.254

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.254