Abstract

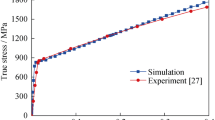

To simulate the effects of hot working parameters on microstructure and flow resistance during dynamic recrystallization (DRX) of a Ni–Cr–Mo-based C276 superalloy, a 2D mesoscopic model has been established using cellular automaton (CA) method. The isothermal hot compression tests were performed on a Gleeble 1500 thermal-mechanical simulator at the temperature range of 1273–1473 K and strain rate range of 0.001–5 s−1. The flow stress behaviors were then obtained and the microstructures of quenching specimen were observed after compression. Then the dislocation density evolution, nucleation and grain growth during hot compression were determined from experiments and integrated to the CA model. The topology of microstructure evolution and deformation resistance were calculated using the developed CA model and compared with the experimental ones. The CA simulation results show reasonable agreements with the experiments, implying the developed CA can capture the effects of processing parameters on the DRX behavior of C276 superalloy.

Similar content being viewed by others

References

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett: Current issues in recrystallization: A review. Mater. Sci. Eng., A 238, 219 (1997).

H.B. Zhang, K.F. Zhang, S.S. Jiang, and Z. Lu: The dynamic recrystallization evolution and kinetics of Ni–18.3Cr–6.4Co–5.9W–4Mo–2.19Al–1.16Ti superalloy during hot deformation. J. Mater. Res. 30, 1029 (2015).

H.W. Son, T.K. Jung, J.W. Lee, and S.K. Hyun: Hot deformation characteristics of CaO-added AZ31 based on kinetic models and processing maps. Mater. Sci. Eng., A 695, 379 (2017).

Y.H. Liu, Y.Q. Ning, Z.K. Yao, Y.Z. Li, J.L. Zhang, and M.W. Fu: Dynamic recrystallization and microstructure evolution of a powder metallurgy nickel-based superalloy under hot working. J. Mater. Res. 31, 2164 (2016).

X.Q. Shang, Z.S. Cui, and M.W. Fu: A ductile fracture model considering stress state and Zener–Hollomon parameter for hot deformation of metallic materials. Int. J. Mech. Sci. 144, 800 (2018).

M.S. Chen, Y.C. Lin, and X.S. Ma: The kinetics of dynamic recrystallization of 42CrMo steel. Mater. Sci. Eng., A 556, 260 (2012).

M.S. Chen, K.K. Li, Y.C. Lin, and W.Q. Yuan: An improved kinetics model to describe dynamic recrystallization behavior under inconstant deformation conditions. J. Mater. Res. 31, 2994 (2016).

C. Zhang, L.W. Zhang, W.F. Shen, C.R. Liu, Y.N. Xia, and R.Q. Li: Study on constitutive modeling and processingmaps for hot deformation of medium carbon Cr–Ni–Mo alloyed steel. Mater. Des. 90, 804 (2016).

X.L. Li, X.L. Li, H.T. Zhou, X. Zhou, F.B. Li, and Q. Liu: Simulation of dynamic recrystallization in AZ80 magnesium alloy using cellular automaton. Comput. Mater. Sci. 140, 95 (2017).

M.S. Chen, W.Q. Yuan, Y.C. Lin, H.B. Li, Z.H. Zou, M.S. Chen, W.Q. Yuan, Y.C. Lin, H.B. Li, and Z.H. Zou: Modeling and simulation of dynamic recrystallization behavior for 42CrMo steel by an extended cellular automaton method. Vacuum 146, 142 (2017).

F. Chen, K. Qi, Z.S. Cui, and X.M. Lai: Modeling the dynamic recrystallization in austenitic stainless steel using cellular automaton method. Comput. Mater. Sci. 83, 331 (2014).

H. Jiang, L. Yang, J.X. Dong, M.C. Zhang, and Z.H. Yao: The recrystallization model and microstructure prediction of alloy 690 during hot deformation. Mater. Des. 104, 162 (2016).

N. Xiao, P. Hodgson, B. Rolfe, and D. Li: Modelling discontinuous dynamic recrystallization using a quantitative multi-order-parameter phase-field method. Comput. Mater. Sci. 155, 298 (2018).

J. Li, H. Xu, T.T. Mattila, J.K. Kivilahti, T. Laurila, and M. Paulasto-Kröckel: Simulation of dynamic recrystallization in solder interconnections during thermal cycling. Comput. Mater. Sci. 50, 690 (2010).

F. Chen, Z.S. Cui, J. Liu, W. Chen, and S.J. Chen: Mesoscale simulation of the high-temperature austenitizing and dynamic recrystallization by coupling a cellular automaton with a topology deformation technique. Mater. Sci. Eng., A 527, 5539 (2010).

S. Shabaniverki and S. Serajzadeh: Simulation of softening kinetics and microstructural events in aluminum alloy subjected to single and multi-pass rolling operations. Appl. Math. Model. 40, 7571 (2016).

R. Ding and Z.X. Guo: Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization. Acta Mater. 49, 3163 (2001).

R. Ding and Z.X. Guo: Microstructural modelling of dynamic recrystallisation using an extended cellular automaton approach. Comput. Mater. Sci. 23, 209 (2002).

J.D. Jaeger, D. Solas, O. Fandeur, J.H. Schmitt, and C. Rey: 3D numerical modeling of dynamic recrystallization under hot working: Application to Inconel 718. Mater. Sci. Eng., A 646, 33 (2015).

F. Han, R.Q. Chen, C.H. Yang, X.M. Li, and D.C. Wang: Cellular automata simulation on dynamic recrystallization of TA16 alloy during hot deformation. Mater. Sci. Forum 849, 245 (2016).

M.S. Chen, W.Q. Yuan, H.B. Li, and Z.H. Zou: Modeling and simulation of dynamic recrystallization behaviors of magnesium alloy AZ31B using cellular automaton method. Comput. Mater. Sci. 136, 163 (2017).

T. Zhang, S.H. Lu, Y.X. Wu, and H. Gong: Optimization of deformation parameters of dynamic recrystallization for 7055 aluminum alloy by cellular automaton. Trans. Nonferrous Met. Soc. China 27, 1327 (2017).

C. Zhang, L.W. Zhang, W.F. Shen, Q.H. Xu, and Y. Cui: The processing map and microstructure evolution of Ni–Cr–Mo-based C276 superalloy during hot compression. J. Alloys Compd. 728, 1269 (2017).

C. Zhang, L.W. Zhang, W.F. Shen, M.F. Li, and S.D. Gu: Characterization of hot deformation behavior of hastelloy C-276 using constitutive equation and processing map. J. Mater. Eng. Perform. 24, 149 (2015).

H. Mecking and U.F. Kocks: Kinetics of flow and strain-hardening. Acta Metall. 29, 1865 (1981).

Y. Zhang, B. Tian, A.A. Volinsky, X. Chen, H. Sun, Z. Chai, P. Liu, and Y. Liu: Dynamic recrystallization model of the Cu–Cr–Zr–Ag alloy under hot deformation. J. Mater. Res. 31, 1275 (2016).

K. Huang and R.E. Logé: A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 111, 548 (2016).

T. Sakai, Y. Nagao, M. Ohashi, and J.J. Jonas: Flow stress and substructural change during transient dynamic recrystallization of nickel. Met. Sci. J. 2, 659 (2013).

L. Madej, M. Sitko, A. Legwand, K. Perzynski, and K. Michalik: Development and evaluation of data transfer protocols in the fully coupled random cellular automata finite element model of dynamic recrystallization. J. Comput. Sci. 26, 66 (2018).

E. Popova, Y. Staraselski, A. Brahme, R.K. Mishra, and K. Inal: Coupled crystal plasticity-Probabilistic cellular automata approach to model dynamic recrystallization in magnesium alloys. Int. J. Plast. 66, 85 (2015).

Y.X. Liu, Y.C. Lin, H.B. Li, D.X. Wen, X.M. Chen, and M.S. Chen: Study of dynamic recrystallization in a Ni-based superalloy by experiments and cellular automaton model. Mater. Sci. Eng., A 626, 432 (2015).

S. Mateusz and M. Lukasz: Development of dynamic recrystallization model based on cellular automata approach. Key Eng. Mater. 622–623, 617 (2014).

E.I. Poliak and J.J. Jonas: A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 44, 127 (1996).

C. Zener and J.H. Hollomon: Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 15, 22 (1944).

Y.X. Liu, Y.C. Lin, and Y. Zhou: 2D cellular automaton simulation of hot deformation behavior in a Ni-based superalloy under varying thermal-mechanical conditions. Mater. Sci. Eng., A 691, 88 (2017).

Y.N. Xia, C. Zhang, L.W. Zhang, W.F. Shen, and Q.H. Xu: A comparative study of constitutive models for flow stress behavior of medium carbon Cr–Ni–Mo alloyed steel at elevated temperature. J. Mater. Res. 32, 1 (2017).

G. Kugler and R. Turk: Modeling the dynamic recrystallization under multi-stage hot deformation. Acta Mater. 52, 4659 (2004).

F. Chen, Z.S. Cui, H.A. Ou, and H. Long: Mesoscale modeling and simulation of microstructure evolution during dynamic recrystallization of a Ni-based superalloy. Appl. Phys. A 122, 889 (2016).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51604058), the major state basic research development program of China (973 program) (No. 2015cb057305), the Open Research Fund from the State Key Laboratory of Rolling and Automation, Northeastern University, and the Fundamental Research Funds for the Central Universities of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Tang, X., Zhang, L. et al. Cellular automaton modeling of dynamic recrystallization of Ni–Cr–Mo-based C276 superalloy during hot compression. Journal of Materials Research 34, 3093–3103 (2019). https://doi.org/10.1557/jmr.2019.218

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.218