Abstract

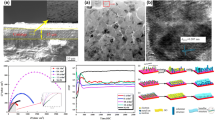

Coatings with low friction coefficient and excellent anti-wear and anticorrosion performances are of great interest for fundamental research and practical applications. In the present study, Cobalt–nickel–phosphorus/graphene oxide (Co–Ni–P/GO) composite coating is prepared by a pulse electrodeposition method. Effect of the embedded GO sheets on the microstructures, microhardness, and electrochemical and tribological behaviors of the Co–Ni–P/GO composite coating are researched in detail. The results reveal that the co-deposition of GO sheets significantly improves the microhardness of the as-prepared Co–Ni–P/GO composite coating and changes the morphology of the Co–Ni–P coating from hemispheric structure to nodule structure with smaller globular particles for the Co–Ni–P/GO composite coating. In addition, friction and wear tests show that the incorporation of GO sheets endows the Co–Ni–P/GO composite coating with remarkable friction reduction and improved wear resistance. Electrochemical corrosion tests demonstrate that the Co–Ni–P/GO composite coating possesses better corrosion resistance than the Co–Ni–P coating.

Similar content being viewed by others

References

M. Leimbach, C. Tschaar, U. Schmidt, and A. Bund: Electrochemical characterization of chromium deposition from trivalent solutions for decorative applications by EQCM and near-surface pH measurements. Electrochim. Acta 270, 104 (2018).

T.R. Tamilarasan, U. Sanjith, M.S. Shankar, and G. Rajagopal: Effect of reduced graphene oxide (rGO) on corrosion and erosion-corrosion behaviour of electroless Ni–P coatings. Wear 390, 385 (2017).

A. Sadeghzadeh-Attar, G. AyubiKia, and M. Ehteshamzadeh: Improvement in tribological behavior of novel sol-enhanced electroless Ni–P–SiO2 nanocomposite coatings. Surf. Coat. Technol. 307, 837 (2016).

L. Wang, Y. Gao, Q. Xue, H. Liu, and T. Xu: A novel electrodeposited Ni–P gradient deposit for replacement of conventional hard chromium. Surf. Coat. Technol. 200, 3719 (2006).

J. Wang, F.L. Zhang, T. Zhang, W.G. Liu, W.X. Li, and Y.M. Zhou: Preparation of Ni–P-diamond coatings with dry friction characteristics and abrasive wear resistance. Int. J. Refract. Met. Hard Mater. 70, 32 (2017).

L. Wang, Y. Gao, Q. Xue, H. Liu, and T. Xu: Microstructure and tribological properties of electrodeposited Ni–Co alloy deposits. Appl. Surf. Sci. 242, 326 (2005).

R. Jain and R. Pitchumani: Facile fabrication of durable copper based superhydrophobic surfaces via electrodeposition. Langmuir 34, 3159 (2017).

A. Nicolenco, N. Tsyntsaru, J. Fornell, E. Pellicer, J. Reklaitis, D. Baltrunas, H. Cesiulis, and J. Sort: Mapping of magnetic and mechanical properties of Fe–W alloys electrodeposited from Fe(III)-based glycolate-citrate bath. Mater. Des. 139, 429 (2018).

E. Beltowska-Lehman, P. Indyka, A. Bigos, M.J. Szczerba, J. Guspiel, H. Koscielny, and M. Kot: Effect of current density on properties of Ni–W nanocomposite coatings reinforced with zirconia particles. Mater. Chem. Phys. 173, 524 (2016).

A.M. Fernandez, J.A. Turner, B. Lara-Lara, and T.G. Deutsch: Preparation and characterization of Cu–Ga–Se thin films synthesized by electrodeposition: Effect of complexing agent and supporting electrolyte. Mater. Chem. Phys. 213, 324 (2018).

M. Najafi, A.A. Rafati, M.K. Fart, and A. Zare: Effect of the pH and electrodeposition frequency on magnetic properties of binary Co1−xSnx nanowire arrays. J. Mater. Res. 29, 190 (2014).

D.Y. Park, N.V. Myung, M. Schwartz, and K. Nobe: Nanostructured magnetic CoNiP electrodeposits: Structure–property relationships. Electrochim. Acta 47, 2893 (2003).

H. Wang, L. Wan, J. Zhang, Y. Chen, W. Hu, L. Liu, C. Zhong, and Y. Deng: Enhanced microwave absorbing properties of surface-modified Co–Ni–P nanotubes. Mater. Lett. 169, 193 (2016).

M. Rakap, E.E. Kalu, and S. Özkar: Hydrogen generation from the hydrolysis of ammonia borane using cobalt–nickel–phosphorus (Co–Ni–P) catalyst supported on Pd-activated TiO2 by electroless deposition. Int. J. Hydrogen Energy 36, 254 (2011).

S. Mirzamohammadi, H. Khorsand, M. Aliofkhazraei, and D.V. Shtansky: Effect of carbamide concentration on electrodeposition and tribological properties of Al2O3 nanoparticle reinforced nickel nanocomposite coatings. Tribol. Int. 117, 68 (2017).

T. He, Y. He, H. Li, Y. Fan, Q. Yang, and Z. He: A comparative study of effect of mechanical and ultrasound agitation on the properties of pulse electrodeposited Ni–W/MWCNTs composite coatings. J. Alloys Compd. 743, 63 (2018).

M. Zhou, Y. Mai, H. Ling, F. Chen, W. Lian, and X. Jie: Electrodeposition of CNTs/copper composite coatings with enhanced tribological performance from a low concentration CNTs colloidal solution. Mater. Res. Bull. 97, 537 (2018).

S. Wang, S. Han, G. Xin, J. Lin, R. Wei, J. Lian, K. Sun, X. Zu, and Q. Yu: High-quality graphene directly grown on Cu nanoparticles for Cu–graphene nanocomposites. Mater. Des. 139, 181 (2018).

K. Stenberg, S. Dittrick, S. Bose, and A. Bandyopadhyay: Influence of simultaneous addition of carbon nanotubes and calcium phosphate on wear resistance of 3D-printed Ti6Al4V. J. Mater. Res. 33, 2077 (2018).

J. Wang, W. Wang, and J. Jia: The oxidation resistance and tribological properties of Ni-based composites with in situ/ex situ Al2O3 and TiC ceramic phases at high temperatures. J. Mater. Res. 31, 3262 (2016).

S. Qiu, G. Liu, W. Li, H. Zhao, and L. Wang: Noncovalent exfoliation of graphene and its multifunctional composite coating with enhanced anticorrosion and tribological performance. J. Alloys Compd. 747, 60 (2018).

M. Mirzaee, C. Dehghanian, and K.S. Bokati: One-step electrodeposition of reduced graphene oxide on three-dimensional porous nano nickel–copper foam electrode and its use in supercapacitor. J. Electroanal. Chem. 813, 152 (2018).

Y.J. Mai, M.P. Zhou, H.J. Ling, F.X. Chen, W.Q. Lian, and X.H. Jie: Surfactant-free electrodeposition of reduced graphene oxide/copper composite coatings with enhanced wear resistance. Appl. Surf. Sci. 433, 232 (2018).

C. Liu, F. Su, and J. Liang: Producing cobalt–graphene composite coating by pulse electrodeposition with excellent wear and corrosion resistance. Appl. Surf. Sci. 351, 889 (2015).

C.M.P. Kumar, T.V. Venkatesha, and R. Shabadi: Preparation and corrosion behavior of Ni and Ni–graphene composite coatings. Mater. Res. Bull. 48, 1477 (2013).

J. Jiang, C. Feng, W. Qian, L. Zhu, S. Han, and H. Lin: Effect of graphene oxide nanosheets and ultrasonic electrodeposition technique on Ni–Mo/graphene oxide composite coatings. Mater. Chem. Phys. 199, 239 (2017).

Z. Xue, W. Lei, Y. Wang, H. Qian, and Q. Li: Effect of pulse duty cycle on mechanical properties and microstructure of nickel–graphene composite coating produced by pulse electrodeposition under supercritical carbon dioxide. Surf. Coat. Technol. 325, 417 (2017).

Q. Zhang, Z. Qin, Q. Luo, Z. Wu, L. Liu, B. Shen, and W. Hu: Microstructure and nanoindentation behavior of Cu composites reinforced with graphene nanoplatelets by electroless co-deposition technique. Sci. Rep. 7, 1338 (2017).

T.S.N. Sankara Narayanan, I. Baskaran, K. Krishnaveni, and S. Parthiban: Deposition of electroless Ni–P graded coatings and evaluation of their corrosion resistance. Surf. Coat. Technol. 200, 3438 (2006).

L. Qiao, Y. Wu, S. Hong, Y. Qin, W. Shi, and G. Li: Corrosion behavior of HVOF-sprayed Fe-based alloy coating in various solutions. J. Mater. Eng. Perform. 26, 3813 (2017).

A.A. Aal, S.M. El-Sheikh, and Y.M.Z. Ahmed: Electrodeposited composite coating of Ni–W–P with nano-sized rod- and spherical-shaped SiC particles. Mater. Res. Bull. 44, 151 (2009).

N.S. Qu, D. Zhu, and K.C. Chan: Fabrication of Ni–CeO2 nanocomposite by electrodeposition. Scr. Mater. 54, 1421 (2006).

Y.J. Mai, J.P. Tu, C.D. Gu, and X.L. Wang: Graphene anchored with nickel nanoparticles as a high-performance anode material for lithium ion batteries. J. Power Sources 209, 1 (2012).

Y.J. Mai, X.L. Wang, J.Y. Xiang, Y.Q. Qiao, D. Zhang, C.D. Gu, and J.P. Tu: CuO/graphene composite as anode materials for lithium-ion batteries. Electrochim. Acta 56, 2306 (2011).

Acknowledgments

The authors are grateful to the financial support of the National Natural Science Foundation of China (51805089).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Wei, D., Huang, X. et al. Electrodeposition of Co–Ni–P/graphene oxide composite coating with enhanced wear and corrosion resistance. Journal of Materials Research 34, 1726–1733 (2019). https://doi.org/10.1557/jmr.2019.15

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.15