Abstract

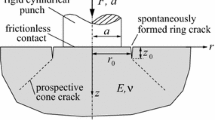

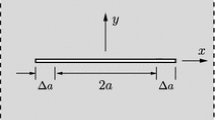

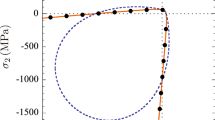

A fracture analysis is developed for crack initiation sequences occurring during sharp indentation of brittle materials. Such indentations, generated by pyramidal or conical loading, generate elastic and plastic deformation. The analysis uses a nonlinear elements-in-series model to describe indentation load–displacement responses, onto which lateral, radial, cone, and median crack initiation points are located. The crack initiation points are determined by extension and application of a contact stress-field model coupled to the indentation load, originally developed by Yoffe, in combination with crack nuclei coupled to the indentation displacement to arrive at an explicit fracture model. Parameters in the analysis are adapted directly from experimental fracture and deformation measurements, and the analysis outputs are directly comparable to experimental observations. After adaptation, crack initiation loads and sequences during indentation loading and unloading of glasses and crystals are predicted by the model from material modulus, hardness, and toughness values to within about 25% of peak contact load. This work is dedicated to George M. Pharr IV on the occasion of his 65th birthday in recognition of his contributions to indentation mechanics.

Similar content being viewed by others

References

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

A.J. Gayle and R.F. Cook: Mapping viscoelastic and plastic properties of polymers and polymer–nanotube composites using instrumented indentation. J. Mater. Res. 31, 2347 (2016).

R.F. Cook: A flexible model for instrumented indentation of viscoelastic–plastic materials. MRS Commun. 8, 586 (2018a).

R.F. Cook: Model for instrumented indentation of brittle open-cell foam. MRS Commun. 8, 1267 (2018b).

R.F. Cook and G.M. Pharr: Direct observation and analysis of indentation cracking in glasses and ceramics. J. Am. Ceram. Soc. 73, 787 (1990).

R.F. Cook, E.G. Liniger, and M.R. Pascucci: Indentation fracture of polycrystalline cubic materials. J. Hard Mater. 5, 190 (1994).

R. Tandon, D.J. Green, and R.F. Cook: Surface stress effects on indentation fracture sequences. J. Am. Ceram. Soc. 73, 2619 (1990).

R. Tandon and R.F. Cook: Cone crack nucleation at sharp contacts. J. Am. Ceram. Soc. 75, 2877 (1992).

R. Tandon and R.F. Cook: Indentation crack initiation and propagation in tempered glass. J. Am. Ceram. Soc. 76, 885 (1993).

M.M. Chaudhri and Y. Enomoto: In situ observations of indentation damage in single crystals of MgO. Wear 233–235, 717 (1999).

J. Thurn, D.J. Morris, and R.F. Cook: Depth-sensing indentation at macroscopic dimensions. J. Mater. Res. 17, 2679 (2002).

J. Thurn and R.F. Cook: Indentation-induced deformation at ultramicroscopic and macroscopic contacts. J. Mater. Res. 19, 124 (2004a).

S. Yoshida, M. Kato, A. Yokota, S. Sasaki, A. Yamada, J. Matsuoka, N. Soga, and C.R. Kurkjian: Direct observation of indentation deformation and cracking of silicate glasses. J. Mater. Res. 30, 2291 (2015).

M.L. Oyen and R.F. Cook: Load–displacement behavior during sharp indentation of viscous–elastic–plastic materials. J. Mater. Res. 18, 139 (2003).

R.F. Cook and M.L. Oyen: Nanoindentation behavior and mechanical properties measurement of polymeric materials. Int. J. Mater. Res. 98, 370 (2007).

E.H. Yoffe: Elastic stress fields caused by indenting brittle materials. Philos. Mag. A 46, 617 (1982).

S. Lathabai, J. Rödel, T. Dabbs, and B.R. Lawn: Fracture mechanics model for subtheshold indentation flaws: Part I equilibrium fracture. J. Mater. Sci. 26, 2157 (1991).

R.F. Cook: Fracture mechanics of the scratch strength of polycrystalline alumina. J. Am. Ceram. Soc. 100, 1146 (2017).

V.R. Howes: Surface strength of coated glass. Glass Technol. 15, 148 (1974).

A. Arora, D.B. Marshall, B.R. Lawn, and M.V. Swain: Indentation deformation/fracture of normal and anomalous glasses. J. Non-Cryst. Solids 31, 415 (1979).

D.B. Marshall and B.R. Lawn: Residual stress effects in sharp contact cracking Part 1: Indentation fracture mechanics. J. Mater. Sci. 14, 2001 (1979).

B.R. Lawn, T.P. Dabbs, and C.J. Fairbanks: Kinetics of shear activated indentation crack initiation in soda-lime glass. J. Mater. Sci. 18, 2785 (1983).

J. Alcalá: Instrumented micro-indentation of zirconia ceramics. J. Am. Ceram. Soc. 83, 1977 (2000).

J. Thurn and R.F. Cook: Mechanical and thermal properties of physical vapor deposited alumina films: II, elastic, plastic, fracture and adhesive behavior. J. Mater. Sci. 39, 4809 (2004b).

M. Sakai, N. Hakiri, and T. Miyajima: Instrumented indentation microscope: A powerful tool for the mechanical characterization in microscales. J. Mater. Res. 21, 2298 (2006).

S.S. Chiang, D.B. Marshall, and A.G. Evans: The response of solids to elastic/plastic indentation. I. Stresses and residual stresses. J. Appl. Phys. 53, 298 (1982a).

S.S. Chiang, D.B. Marshall, and A.G. Evans: The response of solids to elastic/plastic indentation. II. Fracture initiation. J. Appl. Phys. 53, 312 (1982b).

X. Chen, J.W. Hutchinson, and A.G. Evans: The mechanics of indentation induced lateral cracking. J. Am. Ceram. Soc. 88, 1233 (2005).

Y-W. Rhee, H-W. Kim, Y. Deng, and B.R. Lawn: Brittle fracture versus quasi plasticity in ceramics: A simple predictive index. J. Am. Ceram. Soc. 84, 561 (2001).

G. Feng, S. Qu, Y. Huang, and W.D. Nix: An analytical expression for the stress field around an elastoplastic indentation/contact. Acta Mater. 55, 2929 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cook, R.F. Fracture sequences during elastic–plastic indentation of brittle materials. Journal of Materials Research 34, 1633–1644 (2019). https://doi.org/10.1557/jmr.2019.112

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.112