Abstract

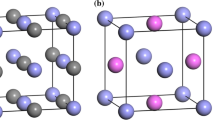

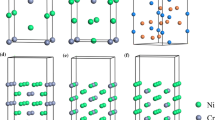

The TiCxN1−x(001)/TiC(001) interface was studied by the first-principles method to provide the theoretical basis for developing TiCxN1−x/TiC coatings. The partial density of state (PDOS), charge density, charge density difference, and Mulliken population analysis were utilized to investigate the bonding nature and the electronic characteristic of the TiC0.25N0.75/TiC interface. The corresponding results indicate that the bonding nature at the interface is ionic and covalent characteristics, which also exist in bulk materials. The extreme similarity of PDOS among interfacial C, N, and Ti atoms and their bulk counterparts reveals that the electronic structure transition at the interface is smooth. The results of Mulliken population analysis and plots of charge density and charge density difference demonstrate that the charge increased for C in the TiC side is less than that for N in the TiC0.25N0.75 side, which reveals that the ionic bond in TiC0.25N0.75 is stronger than that in TiC. Therefore, TiC0.25N0.75 coating can be an alternative choice to combine with TiC coating in the actual production process of multilayer coatings.

Similar content being viewed by others

References

J. Kim and S. Kang: Elastic and thermo-physical properties of TiC, TiN, and their intermediate composition alloys using ab initio calculations. J. Alloys Compd. 528, 20 (2012).

G. Zhang, B. Li, B. Jiang, F. Yan, and D. Chen: Microstructure and tribological properties of TiN, TiC, and Ti(C,N) thin films prepared by closed-field unbalanced magnetron sputtering ion plating. Appl. Surf. Sci. 255, 8788 (2009).

T. Li, T. Liu, H. Wei, S. Hussain, B. Miao, W. Zeng, X. Peng, and F. Pan: Atomic and electronic structure of the TiN/MgO interface from first principles. Comput. Mater. Sci. 105, 83 (2015).

N. Liu, W. Yin, and L. Zhu: Effect of TiC/TiN powder size on microstructure and properties of Ti(C,N)-based cermets. Mater. Sci. Eng., A 445–446, 707 (2007).

J. Kim, H. Kwon, and C.W. Kwon: Temperature dependent phase stability of Ti(C1−xNx) solid solutions using first-principles calculations. Ceram. Int. 43, 650 (2017).

S. Cardinal, A. Malchère, V. Garnier, and G. Fantozzi: Microstructure and mechanical properties of TiC–TiN based cermets for tools application. Int. J. Refract. Met. Hard Mater. 27, 521 (2009).

S.H. Kim, Y.J. Baik, and D. Kwon: Analysis of interfacial strengthening from composite hardness of TiN/VN and TiN/NbN multilayer hard coatings. Surf. Coat. Technol. 187, 47 (2004).

Y. Zhao, G. Lin, J. Xiao, C. Dong, and L. Wen: TiN/TiC multilayer films deposited by pulse biased arc ion plating. Vacuum 85, 1 (2010).

E.R. Parra, P.J.A. Arango, and V.J.B. Palacio: XPS structure analysis of TiN/TiC bilayers produced by pulsed vacuum arc discharge. Dyna 77, 64 (2010).

C. Liu, A. Leyland, Q. Bi, and A. Matthews: Corrosion resistance of multi-layered plasma-assisted physical vapour deposition TiN and CrN coatings. Surf. Coat. Technol. 141, 164 (2001).

M. Azadi, A.S. Rouhaghdam, S. Ahangarani, and H.H. Mofidi: Mechanical behavior of TiN/TiC multilayer coatings fabricated by plasma assisted chemical vapor deposition on AISI H13 hot work tool steel. Surf. Coat. Technol. 245, 156 (2014).

J. Zhang, Q. Xue, and S. Li: Microstructure and corrosion behavior of TiC/Ti(CN)/TiN multilayer CVD coatings on high strength steels. Appl. Surf. Sci. 280, 626 (2013).

S.K. Michelic, D. Loder, T. Reip, A.A. Barani, and C. Bernhard: Characterization of TiN, TiC, and Ti(C,N) in titanium-alloyed ferritic chromium steels focusing on the significance of different particle morphologies. Mater. Charact. 100, 61 (2015).

J.M. Lackner, W. Waldhauser, and R. Ebner: Large-area high-rate pulsed laser deposition of smooth TiCxN1−x coatings at room temperature-mechanical and tribological properties. Surf. Coat. Technol. 188–189, 519 (2004).

H. Xiong, Y. Wen, X. Gan, Z. Li, and L. Chai: Influence of coarse TiCN content on the morphology and mechanical properties of ultrafine TiCN-based cermets. Mater. Sci. Eng., A 682, 648 (2017).

J. Smolik and K. Zdunek: Effect of interlayer composition on the tribological properties of TiC/Ti(Cx,N1−x)/TiN anti-abrasive multi-layer coatings. Vacuum 55, 147 (1999).

M. Yasuoka, P. Wang, and R. Murakami: Comparison of the mechanical performance of cutting tools coated by either a TiCxN1−x single-layer or a TiC/TiC0.5N0.5/TiN multilayer using the hollow cathode discharge ion plating method. Surf. Coat. Technol. 206, 2168 (2012).

J. Zhang, Q. Xue, S. Li, and Z. Qin: Microstructure, corrosion and tribological properties of Ti(CN) multilayer coatings on 35CrMo steel by CVD. Rare Met. 1, 1–7 (2014).

X. Guo, Y. Zhang, Y. Jung, L. Li, J. Knapp, and J. Zhang: Ideal tensile strength and shear strength of ZrO2(111)/Ni(111) ceramic–metal interface: A first principle study. Mater. Des. 112, 254 (2016).

D. Yin, X. Peng, Y. Qin, and Z. Wang: Electronic property and bonding configuration at the TiN(111)/VN(111) interface. J. Appl. Phys. 108, 033714 (2010).

L.H. Liang, X.M. You, H.S. Ma, and Y.G. Wei: Interface energy and its influence on interface fracture between metal and ceramic thin films in nanoscale. J. Appl. Phys. 108, 084317 (2010).

A. Zaoui, B. Bouhafs, and P. Ruterana: First-principles calculations on the electronic structure of TiCxN1−x, ZrxNb1−xC and HfCxN1−x alloys. Mater. Chem. Phys. 91, 108 (2005).

J. Li, Y. Yang, L. Li, J. Lou, X. Luo, and B. Huang: Interfacial properties and electronic structure of β-SiC(111)/α-Ti(0001): A first principle study. J. Appl. Phys. 113, 023516 (2013).

X. Fan, B. Chen, M. Zhang, D. Li, Z. Liu, and C. Xiao: First-principles calculations on bonding characteristic and electronic property of TiC(111)/TiN(111) interface. Mater. Des. 112, 282 (2016).

H.T. Chen and M.F. Yan: Population analysis solution to hardness enhancement in TiCxN1−x. Physica B 407, 1183 (2012).

S. Yi, H. Yin, J. Zheng, D.F. Khan, and X. Qu: The first-principles study on the mechanical and electronic properties about rim phase and hard phase of Ti(C,N) based cermets. Comput. Mater. Sci. 79, 417 (2013).

Y. Yang, H. Lu, C. Yu, and J.M. Chen: First-principles calculations of mechanical properties of TiC and TiN. J. Alloys Compd. 485, 542 (2009).

J. Li, Y. Yang, G. Feng, X. Luo, Q. Sun, and N. Jin: Adhesion and fracture toughness at α-Ti(0001)/TiC(111): A first-principles investigation. Appl. Surf. Sci. 286, 240 (2013).

Y. Kim and B. Lee: Modified embedded-atom method interatomic potentials for the Ti–C and Ti–N binary systems. Acta Mater. 56, 3481 (2008).

J. Yang, J. Huang, D. Fan, S. Chen, and X. Zhao: LaAlO3 as the heterogeneous nucleus of ferrite: Experimental investigation and theoretical calculation. J. Alloys Compd. 683, 357 (2016).

S.V. Dudiy and B.I. Lundqvist: First-principles density-functional study of metal-carbonitride interface adhesion: Co/TiC(001) and Co/TiN(001). Phys. Rev. B 64, 045403 (2001).

L. Fang, L. Wang, J. Gong, H. Dai, and D. Miao: First-principles study of bulk and (001) surface of TiC. Trans. Nonferrous Met. Soc. China 20, 857 (2010).

J. Yang, P. Zhang, Y. Zhou, J. Guo, X. Ren, Y. Yang, and Q. Yang: First-principles study on ferrite/TiC heterogeneous nucleation interface. J. Alloys Compd. 556, 160 (2013).

X. Zhao, X. Yuan, S. Liu, C. Zhao, C. Wang, Y. Zhou, and Q. Yang: Investigation on WC/LaAlO3 heterogeneous nucleation interface by first-principles. J. Alloys Compd. 695, 1753 (2017).

ACKNOWLEDGMENT

This work was supported by the Fundamental Research Funds for the Central Universities of China (2682014CX004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, X., Wang, S., Yang, X. et al. Bonding characteristic and electronic property of TiCxN1−x(001)/TiC(001) interface: A first-principles study. Journal of Materials Research 33, 1650–1658 (2018). https://doi.org/10.1557/jmr.2018.79

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.79