Abstract

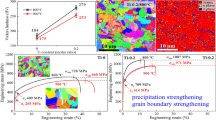

Laves phase plays a positive role in improving the strength of high-entropy alloys (HEAs); Nb and Ti elements have potential to promote Laves phase formation in some HEAs. For improving the strength of the face-centered cubic (FCC) CoCrFeMnNi HEA, a series of (CoCrFeMnNi)100−xNbx (atomic ratio: x = 0, 4, 8, 12, 16) and (CoCrFeMnNi)100−xTix (atomic ratio: x = 0, 2, 4, 6, 8, 12) HEAs were prepared by melting. The effects of Nb and Ti on the microstructure evolution and compressive properties of the CoCrFeMnNi HEAs were investigated. For (CoCrFeMnNi)100−xNbx HEAs, the second-phase (Laves and σ phase) volume fraction increased from 0 to 42%. The yield strength also increased gradually from 202 to 1010 MPa. However, the fracture strain decreased from 60% (no fracture) to 12% with increasing Nb content. For (CoCrFeMnNi)100−xTix HEAs, the yield strength increased from 202 to 1322 MPa. The Laves phase volume fraction also increased from 0 to 27%. However, the fracture strain decreased from 60% (no fracture) to 7.5% with increasing Ti content. Addition of Nb and Ti has a good effect on improving the strength of FCC CoCrFeMnNi HEA.

Similar content being viewed by others

References

S.J. Sun, Y.Z. Tian, H.R. Lin, X.G. Dong, Y.H. Wang, Z.J. Zhang, and Z.F. Zhang: Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure. Mater. Des. 133, 122 (2017).

S.J. Sun, Y.Z. Tian, H.R. Lin, H.J. Yang, X.G. Dong, Y.H. Wang, and Z.F. Zhang: Transition of twinning behavior in CoCrFeMnNi high entropy alloy with grain refinement. Mater. Sci. Eng., A 712, 603 (2018).

Y. Ma, Q. Wang, C. Li, L. Santodonato, M. Feygenson, C. Dong, and P.K. Liaw: Chemical short-range orders and the induced structural transition in high-entropy alloys. Scr. Mater. 64, 144 (2018).

W.Q. Wu, S. Ni, Y. Liu, and M. Song: Effects of cold rolling and subsequent annealing on the microstructure of a HfNbTaTiZr high-entropy alloy. J. Mater. Res. 31, 3815 (2016).

Y. Zhang, Y. Liu, and T.X. Li: Microstructure and mechanical properties of a refractory HfNbTiVSi0.5 high-entropy alloy composite. Mater. Lett. 174, 82 (2016).

Y. Liu, Y. Zhang, H. Zhang, N.J. Wang, X. Chen, H.W. Zhang, and Y.X. Li: Microstructure and mechanical properties of refractory HfMo0.5NbTiV0.5Six high-entropy composites. J. Alloys Compd. 694, 869 (2017).

Y. Liu, M. Chen, Y.X. Li, and X. Chen: Microstructure and mechanical performance of AlxCoCrCuFeNi high-entropy alloys. Rare Met. Mater. Eng. 38, 602 (2009).

X.W. Liu, L. Liu, G. Liu, X.X. Wu, D.H. Lu, J.Q. Yao, W.M. Jiang, Z.T. Fan, and W.B. Zhang: The role of carbon in grain refinement of cast CrFeCoNi high-entropy alloys. Metall. Mater. Trans. A 49, 2151 (2018).

Y.P. Lu, Y. Dong, S. Guo, L. Jiang, H.J. Kang, T.M. Wang, B. Wen, Z.J. Wang, J.C. Jie, Z.Q. Cao, H.H. Ruan, and T.J. Li: A promising new class of high-temperature alloys: Eutectic high-entropy alloys. Sci. Rep. 4, 6200 (2014).

Y.P. Lu, X.Z. Gao, L. Jiang, Z.N. Chen, T.M. Wang, J.C. Jie, H.J. Kang, Y.B. Zhang, S. Guo, H.H. Ruan, Y.H. Zhao, Z.Q. Cao, and T.J. Li: Directly cast bulk eutectic and near-eutectic high entropy alloys with balanced strength and ductility in a wide temperature range. Acta Mater. 124, 143 (2017).

J.Q. Yao, X.W. Liu, N. Gao, Q.H. Jiang, N. Li, G. Liu, W.B. Zhang, and Z.T. Fan: Phase stability of a ductile single-phase BCC Hf0.5Nb0.5Ta0.5Ti1.5Zr refractory high-entropy alloy. Intermetallics 98, 79 (2018).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 213, 375 (2004).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu: Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 62, 105 (2014).

N.D. Stepanov, D.G. Shaysultanov, G.A. Salishchev, M.A. Tikhonovsky, E.E. Oleynik, A.S. Tortika, and O.N. Senkov: Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J. Alloys Compd. 628, 170 (2015).

W.H. Liu, J.Y. He, H.L. Huang, H. Wang, Z.P. Lu, and C.T. Liu: Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys. Intermetallics 60, 1 (2015).

X.F. Wang, Y. Zhang, Y. Qiao, and G.L. Chen: Novel microstructure and properties of multicomponent CoCrCuFeNiTix, alloys. Intermetallics 15, 357 (2007).

W.Y. Huo, H. Zhou, F. Fang, Z.H. Xie, and J.Q. Jiang: Microstructure and mechanical properties of CoCrFeNiZrx eutectic high-entropy alloys. Mater. Des. 134, 226 (2017).

W.Y. Huo, H. Zhou, F. Fang, X.F. Zhou, Z.H. Xie, and J.Q. Jiang: Microstructure and properties of novel CoCrFeNiTax eutectic high-entropy alloys. J. Alloys Compd. 735, 897 (2018).

T.T. Shun, L.Y. Chang, and M.H. Shiu: Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys. Mater. Sci. Eng., A 556, 170 (2012).

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu: Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 116, 332 (2016).

H. Jiang, L. Jiang, D.X. Qiao, Y.P. Lu, T.M. Wang, Z.Q. Cao, and T.J. Li: Effect of niobium addition on microstructure and properties of the CoCrFeNbxNi high entropy alloys. J. Mater. Sci. Technol. 33, 712 (2016).

F. He, Z. Wang, P. Cheng, Q. Wang, J.J. Li, Y.Y. Dang, J.C. Wang, and C.T. Liu: Designing eutectic high entropy alloys of CoCrFeNiNbx. J. Alloys Compd. 656, 284 (2016).

Y. Dong, K.Y. Zhou, Y.P. Lu, X.X. Gao, T.M. Wang, and T.J. Li: Effect of vanadium addition on the microstructure and properties of AlCoCrFeNi high entropy alloy. Mater. Des. 57, 67 (2015).

S.G. Ma and Y. Zhang: Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng., A 532, 480 (2012).

Q.S. Chen, Y.P. Lu, Y. Dong, T.M. Wang, and T.J. Li: Effect of minor B addition on microstructure and properties of AlCoCrFeNi multi-component alloy. Trans. Nonferrous Met. Soc. China 25, 2958 (2015).

J.M. Zhu, H.F. Zhang, H.M. Fu, A.M. Wang, H. Li, and Z.Q. Hu: Microstructures and compressive properties of multicomponent AlCoCrCuFeNiMox alloys. J. Alloys Compd. 497, 52 (2010).

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu: Synthesis and properties of multiprincipal component AlCoCrFeNiSix alloys. Mater. Sci. Eng., A 527, 7210 (2010).

Y. Yu, J. Wang, J.S. Li, H.C. Kou, and W.M. Liu: Characterization of BCC phases in AlCoCrFeNiTix high entropy alloys. Mater. Lett. 138, 78 (2015).

J. Chen, P. Niu, Y. Liu, Y.Y. Lu, X.H. Wang, Y.L. Peng, and J.N. Liu: Effect of Zr content on microstructure and mechanical properties of AlCoCrFeNi high entropy alloy. Mater. Des. 94, 39 (2016).

Z.M. Li, K.G. Pradeep, and Y. Deng: Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227 (2016).

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, and E.P. George: Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 112, 40 (2016).

A. Gali and E.P. George: Tensile properties of high- and medium-entropy alloys. Intermetallics 39, 74 (2013).

F. Otto, N.L. Hanold, and E.P. George: Microstructural evolution after thermo mechanical processing in an equiatomic, single-phase CoCrFeMnNi high entropy alloy with special focus on twin boundaries. Intermetallics 54, 39 (2014).

X. Chen, Y.W. Sui, J.Q. Qi, Y.Z. He, F.X. Wei, Q.K. Meng, and Z. Sun: Microstructure of Al1.3CrFeNi eutectic high entropy alloy and oxidation behavior at 1000 °C. J. Mater. Res. 11, 32 (2017).

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen: Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl. Phys. Lett. 90, 253 (2007).

S.W. Tsai: Theory of Composites Design (Think Composites Press, San Francisco, 1992).

Y. Zhang, Y. Zhou, J. Lin, G. Chen, and P.K. Liaw: Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 10, 534 (2008).

T. Egami and Y. Waseda: Atomic size effect on the formability of metallic glasses. J. Non-Cryst. Solids 64, 113 (1984).

X. Yang and Y. Zhang: Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132, 233 (2012).

S. Guo and C.T. Liu: Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci.: Mater. Int. 21, 433 (2011).

S. Guo, C. Ng, J. Lu, and C.T. Liu: Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 109, 645 (2011).

M.H. Tsai, K.Y. Tsai, C.W. Tsai, C. Lee, C.C. Juan, and J.W. Ye: Criterion for sigma phase formation in Cr- and V-containing high-entropy alloys. Mater. Res. Lett. 1, 207 (2013).

M.H. Tsai, K.C. Chang, J.H. Li, R.C. Tsai, and A.H. Cheng: A second criterion for sigma phase formation in high-entropy alloys. Mater. Res. Lett. 4, 1 (2016).

M.C. Troparevsky, J.R. Morris, P.R.C. Kent, A.R. Lupini, and G.M. Stocks: Criteria for predicting the formation of single-phase high-entropy alloys. Phys. Rev. X 5, 1 (2015).

N. Yurchenko, N. Stepanov, and G. Salishchev: Laves-phase formation criterion for high-entropy alloys. Met. Sci. J. 33, 17 (2016).

O.N. Senkov and D.B. Miracle: A new thermodynamic parameter to predict formation of solid solution or intermetallic phases in high entropy alloys. J. Alloys Compd. 658, 603 (2016).

B.S. Murty, J.W. Yeh, and S. Ranganathan: High Entropy Alloys (Elsevier, London, 2014).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1 (2011).

S. Guo, Q. Hu, C. Ng, and C.T. Liu: More than entropy in high-entropy alloys: Forming solid solutions or amorphous phase. Intermetallics 41, 96 (2013).

Y. Zhang, X. Yang, and P.K. Liaw: Alloy design and properties optimization of high entropy alloys. JOM 64, 830 (2012).

R.R. Chen, G. Qin, H.T. Zheng, L. Wang, Y.Q. Su, Y.L. Chiu, H.S. Ding, J.J. Guo, and H.Z. Fu: Composition design of high entropy alloys using the valence electron concentration to balance strength and ductility. Acta Mater. 144, 129 (2018).

G. Qin, W.T. Xue, C.L. Fan, R.R. Chen, L. Wang, Y.Q. Su, H.S. Ding, and J.J. Guo: Effect of Co content on phase formation and mechanical properties of (AlCoCrFeNi)100−xCox high-entropy alloys. Mater. Sci. Eng., A 710, 200 (2018).

G. Qin, S. Wang, R.R. Chen, X. Gong, L. Wang, Y.Q. Su, J.J. Guo, and H.Z. Fu: Microstructures and mechanical properties of Nb-alloyed CoCrCuFeNi high-entropy alloys. J. Mater. Sci. Technol. 34, 365 (2018).

R. Feng, M.C. Gao, C. Lee, M. Mathes, T.T. Zuo, S.Y. Chen, J.A. Hawk, Y. Zhang, and P.K. Liaw: Design of light-weight high-entropy alloys. Entropy 18, 333 (2016).

Y. Zhang, Z.P. Lu, S.G. Ma, P.K. Liaw, Z. Tang, Y.Q. Cheng, and M.C. Gao: Guidelines in predicting phase formation of high-entropy alloys. MRS Commun. 42, 57 (2014).

B. Chanda and J. Das: Composition dependence on the evolution of nanoeutectic in CoCrFeNiNbx (0.45 ≤ x ≤ 0.65) high entropy alloys. Adv. Eng. Mater. 20, 1700908 (2018).

Acknowledgment

This work was supported by the Fund of State Key Laboratory of Advanced Welding and Joining and National Natural Science Foundation of China (No. 51741404).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, G., Li, Z., Chen, R. et al. CoCrFeMnNi high-entropy alloys reinforced with Laves phase by adding Nb and Ti elements. Journal of Materials Research 34, 1011–1020 (2019). https://doi.org/10.1557/jmr.2018.468

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.468