Abstract

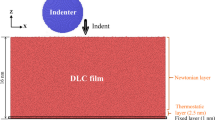

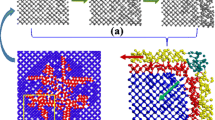

A method for extracting the substrate-independent stress–strain curves of thin films was developed using spherical nanoindentation to investigate the yield behavior of diamond-like carbon (DLC) thin films with Young’s moduli of ∼73 GPa and ∼76 GPa. The resulting stress–strain curves showed that these films commence yielding at ∼13 GPa and ∼14 GPa, respectively. These yield strength values agree with the critical pressure necessary to initiate the transformation of sp2-bonded carbon into significantly harder sp3-bonded carbon, indicating that the yielding of the materials is associated with the sp2-to-sp3 phase transition. The ability of a DLC film to accommodate a progressively increasing contact stress with strain beyond the yield point while dissipating part of the accumulated strain energy, as evidenced in this work, implies a unique mechanism of the brittle material for passively mitigating contact deformation and fracture in tribological applications.

Similar content being viewed by others

References

A. Grill: Diamond-like carbon: State of the art. Diam. Relat. Mater. 8, 428 (1999).

A. Erdemir and C. Donnet: Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D: Appl. Phys. 39, R311 (2006).

N. Fujisawa, D.R. McKenzie, N.L. James, J.C. Woodard, and M.V. Swain: Combined influences of mechanical properties and surface roughness on the tribological properties of amorphous carbon coatings. Wear 260, 62 (2006).

S. Pathak and S.R. Kalidindi: Spherical nanoindentation stress-strain curves. Mater. Sci. Eng. R Rep. 91, 1 (2015).

J. Schwan, S. Ulrich, H. Roth, H. Ehrhardt, S.R.P. Silva, J. Robertson, R. Samlenski, and R. Brenn: Tetrahedral amorphous carbon films prepared by magnetron sputtering and dc ion plating. J. Appl. Phys. 79, 1416 (1996).

J. Schwan, S. Ulrich, T. Theel, H. Roth, H. Ehrhardt, P. Becker, and S.R.P. Silva: Stress-induced formation of high-density amorphous carbon thin films. J. Appl. Phys. 82, 6024 (1997).

W. Lu and K. Komvopoulos: Effect of stress-induced phase transformation on nanomechanical properties of sputtered amorphous carbon films. Appl. Phys. Lett. 82, 2437 (2003).

C. Liu, Y. Lin, Z. Zhou, and K.Y. Li: Dual phase amorphous carbon ceramic achieves theoretical strength limit and large plasticity. Carbon 122, 276 (2017).

D. Tabor: The Hardness of Metals (Clarendon Press, Oxford, U.K., 1951).

J.S. Field and M.V. Swain: A simple predictive model for spherical indentation. J. Mater. Res. 8, 297 (1993).

S.R. Kalidindi and S. Pathak: Determination of the effective zero-point and the extraction of spherical nanoindentation stress-strain curves. Acta Mater. 56, 3523 (2008).

H. Hertz: Miscellaneous Papers, D.E. Jones and G.A. Schott eds. (Macmillan, London, U.K., 1896); pp. 146–183.

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

A.C. Fischer-Cripps: Nanoindentation, 3rd ed. (Springer, New York, NY, 2011); pp. 8–10, 24, 43–46, 150–152.

J. Hay and B. Crawford: Measuring substrate-independent modulus of thin films. J. Mater. Res. 26, 727 (2011).

H. Gao, C.H. Chiu, and J. Lee: Elastic contact versus indentation modeling of multi-layered materials. Int. J. Solid Struct. 29, 2471 (1992).

H. Song: Selected mechanical problems in load and depth sensing indentation testing. Ph.D. thesis, Rice University, Houston, TX, 1999, pp. 51–72.

C. Lenardi, M.A. Baker, V. Briois, L. Nobili, P. Piseri, and W. Gissler: Properties of amorphous a-CH(:N) films synthesized by direct ion beam deposition and plasma-assisted chemical vapour deposition. Diam. Relat. Mater. 8, 595 (1999).

N. Fujisawa, T.F. Zhang, B.H. Lee, and K.H. Kim: A robust method for extracting the mechanical properties of thin films with rough surfaces by nanoindentation. J. Mater. Res. 23, 3777 (2016).

S.J. Cho, K.R. Lee, K.Y. Eun, J.H. Hahn, and D.H. Ko: Determination of elastic modulus and Poisson’s ratio of diamond-like carbon films. Thin Solid Films 341, 207 (1999).

R. Saha and W.D. Nix: Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 50, 23 (2002).

G.G. Stoney: The tension of metallic films deposited by electrolysis. Proc. R. Soc. London, Ser. A 82, 172 (1909).

K. Zhou, P. Ke, X. Li, Y. Zou, and A. Wang: Microstructure and electrochemical properties of nitrogen-doped DLC films deposited by PECVD technique. Appl. Surf. Sci. 329, 281 (2015).

L. Qiang, B. Zhang, Y. Zhou, and J. Zhang: Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci. 20, 17 (2013).

J.G. Swadener, B. Taljat, and G.M. Pharr: Measurement of residual stress by load and depth sensing indentation with spherical indenters. J. Mater. Res. 16, 2091 (2001).

J.Z. Hu, L.D. Merkle, C.S. Menoni, and I.L. Spain: Crystal data for high-pressure phases of silicon. Phys. Rev. B 34, 4679 (1986).

A. Leyland and A. Matthrew: On the significance of the H / E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 246, 1 (2000).

M. Sakai: Energy principle of the indentation-induced inelastic surface deformation and hardness of brittle materials. Acta Metall. Mater. 41, 1751 (1993).

K.L. Johnson: The correlation of indentation experiments. J. Mech. Phys. Solid. 18, 115 (1970).

A.G. Atkins and D. Tabor: Plastic indentation in metals with cones. J. Mech. Phys. Solid. 13, 149 (1965).

S.D. Mesarovic and N.A. Fleck: Spherical indentation of elastic-plastic solids. Proc. R. Soc. London, Ser. A 455, 2707 (1999).

Y.J. Park and G.M. Pharr: Nanoindentation with spherical indenters: Finite element studies of deformation in the elastic-plastic transition regime. Thin Solid Films 447–448, 246 (2004).

C. Meade and R. Jeanloz: Frequency-dependent equation of state of fused silica to 10 GPa. Phys. Rev. B 35, 236 (1987).

F.P. Bundy, W.A. Bassett, M.S. Weathers, R.J. Hemley, H.U. Mao, and A.F. Goncharov: The pressure-temperature phase and transformation diagram for carbon; updated through 1994. Carbon 34, 141 (1996).

W. Guo, C.Z. Zhu, T.X. Yu, C.H. Woo, B. Zhang, and Y.T. Dai: Formation of sp3 bonding in nanoindented carbon nanotubes and graphite. Phys. Rev. Lett. 93, 245502 (2004).

ACKNOWLEDGMENTS

This study was supported by Global Frontier Program through the Global Frontier Hybrid Interface Materials (GFHIM) of the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (2013M3A6B1078873 and 2013M3A6B1078874). The authors also acknowledge support from Hysitron, Inc. on the state-of-the-art TI 950 TriboIndenter® nanomechanical test instrument used for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fujisawa, N., Zhang, T.F., Li, O.L. et al. Substrate-independent stress–strain behavior of diamond-like carbon thin films by nanoindentation with a spherical tip. Journal of Materials Research 33, 699–708 (2018). https://doi.org/10.1557/jmr.2018.45

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.45