Abstract

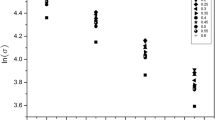

In this paper, the influence of strain rate on the mechanical behavior of high-strength low-alloy (HC420LA) steel were studied. Quasi-static and dynamic tensile experiments were performed with strain rates ranging from 0.001 to 500 s−1 at room temperature. The digital image correlation technique was used to obtain the full-field strain. The experimental results showed that HC420LA steel exhibited positive strain rate sensitivity. Based on experimental results, the modified Johnson–Cook (J–C) model was used to model the constitutive behavior of HC420LA steel. Predictions of the standard and modified J–C models were compared using standard statistical parameters. The modified J–C model showed better agreement with the experimental data. Then, numerical simulation of the representative tensile test at a strain rate of 100 s−1 was performed using the finite element code LS-DYNA. Good correlation between the experimental and numerical simulation results was achieved.

Similar content being viewed by others

References

R. Oyyaravelu, P. Kuppan, and N. Arivazhagan: Metallurgical and mechanical properties of laser welded high strength low alloy steel. J. Adv. Res. 7, 463 (2016).

G. Han, Z.J. Xie, L. Xiong, C.J. Shang, and R.D.K. Misra: Evolution of nano-size precipitation and mechanical properties in a high strength-ductility low alloy steel through intercritical treatment. Mater. Sci. Eng., A 705, 89 (2017).

A. Macwan, A. Kumar, and D.L. Chen: Ultrasonic spot welded 6111-T4 aluminum alloy to galvanized high-strength low-alloy steel: Microstructure and mechanical properties. Mater. Des. 113, 284 (2017).

Y. Li, X.L. Wan, W.Y. Lu, A.A. Shirzadi, O. Isayev, O. Hress, and K.M. Wu: Effect of Zr–Ti combined deoxidation on the microstructure and mechanical properties of high-strength low-alloy steels. Mater. Sci. Eng., A 659, 179 (2016).

A.S. Khan, M. Baig, S.H. Choi, H.S. Yang, and X. Sun: Quasi-static and dynamic responses of advanced high strength steels: Experiments and modeling. Int. J. Plast. 30–31, 1 (2012).

J.H. Kim, D. Kim, H.N. Han, F. Barlat, and M.G. Lee: Strain rate dependent tensile behavior of advanced high strength steels: Experiment and constitutive modeling. Mater. Sci. Eng., A 559, 222 (2013).

W. Wang, M. Li, C. He, X. Wei, D. Wang, and H. Du: Experimental study on high strain rate behavior of high strength 600–1000 MPa dual phase steels and 1200 MPa fully martensitic steels. Mater. Des. 47, 510 (2013).

J. Qin, R. Chen, X. Wen, Y. Lin, M. Liang, and F. Lu: Mechanical behaviour of dual-phase high-strength steel under high strain rate tensile loading. Mater. Sci. Eng., A 586, 62 (2013).

N.K. Singh, E. Cadoni, M.K. Singha, and N.K. Gupta: Dynamic tensile behavior of multi phase high yield strength steel. Mater. Des. 32, 5091 (2011).

H. Fathi, E. Emadoddin, and H.R. Mohammadian Semnani: Simulation and experimental investigation of strain rate impact on martensitic transformation in 304L steel through dome test. J. Mater. Res. 31, 2136 (2016).

G.M. Smith, O. Higgins, and S. Sampath: In situ observation of strain and cracking in coated laminates by digital image correlation. Surf. Coat. Technol. 328, 211 (2017).

G. Valeri, B. Koohbor, A. Kidane, and M.A. Sutton: Determining the tensile response of materials at high temperature using DIC and the virtual fields method. Optic Laser. Eng. 91, 53 (2017).

M. Flores, D. Mollenhauer, V. Runatunga, T. Beberniss, D. Rapking, and M. Pankow: High-speed 3D digital image correlation of low-velocity impacts on composite plates. Composites, Part B 131, 153 (2017).

V. Tarigopula, O.S. Hopperstad, M. Langseth, A.H. Clausen, and F. Hild: A study of localisation in dual-phase high-strength steels under dynamic loading using digital image correlation and FE analysis. Int. J. Solids Struct. 45, 601 (2008).

D.J. Wu, W.G. Mao, Y.C. Zhou, and C. Lu: Digital image correlation approach to cracking and decohesion in a brittle coating/ductile substrate system. Appl. Surf. Sci. 257, 6040 (2011).

X. Chen, C. Niu, C. Lian, and J. Lin: The evaluation of formability of the 3rd generation advanced high strength steels QP980 based on digital image correlation method. Procedia Eng. 207, 556 (2017).

A.D. Kammers, J. Wongsangam, T.G. Langdon, and S. Daly: The microstructure length scale of strain rate sensitivity in ultrafine-grained aluminum. J. Mater. Res. 30, 981 (2015).

J. Peirs, P. Verleysen, W.V. Paepegem, and J. Degrieck: Determining the stress–strain behaviour at large strains from high strain rate tensile and shear experiments. Int. J. Impact Eng. 38, 406 (2011).

Y. Zhao, J. Sun, J. Li, Y. Yan, and P. Wang: A comparative study on Johnson–Cook and modified Johnson–Cook constitutive material model to predict the dynamic behavior laser additive manufacturing FeCr alloy. J. Alloys Compd. 723, 179 (2017).

L. Chang, C. Zhou, J. Peng, J. Li, and X. He: Fields–Backofen and a modified Johnson–Cook model for CP-Ti at ambient and intermediate temperature. Rare Met. Mater. Eng. 46, 1803 (2017).

S. Sahu, D.P. Mondal, M.D. Goel, M.Z. Ansari, and Z. Ansari: Finite element analysis of AA1100 elasto-plastic behaviour using Johnson–Cook model. Mater. Today 5, 5349 (2018).

J. Chen, J. Li, and Z. Li: Experiment research on rate-dependent constitutive model of Q420 steel. Constr. Build. Mater. 153, 816 (2017).

M.M. Gurusamy and B.C. Rao: On the performance of modified Zerilli–Armstrong constitutive model in simulating the metal-cutting process. J. Manuf. Process. 28, 253 (2017).

O. Sabokpa, A. Zarei-Hanzaki, H.R. Abedi, and N. Haghdadi: Artificial neural network modeling to predict the high temperature flow behavior of an AZ81 magnesium alloy. Mater. Des. 39, 390 (2012).

Acknowledgment

This project is supported by The National Key Research and Development Program of Hunan Province (2017GK2090).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

43578_2019_34061034_MOESM1_ESM.docx

Supplementary Material for: A study on the constitutive equation of HC420LA steel subjected to high strain rates (approximately 1.86 MB)

Rights and permissions

About this article

Cite this article

Cui, J., Wang, Q., Dong, D. et al. A study on the constitutive equation of HC420LA steel subjected to high strain rates. Journal of Materials Research 34, 1034–1042 (2019). https://doi.org/10.1557/jmr.2018.439

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.439