Abstract

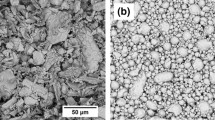

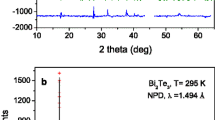

Traditional manufacturing methods restrict the expansion of thermoelectric technology. Here, we demonstrate a new manufacturing approach for thermoelectric materials. Selective laser melting, an additive manufacturing technique, is performed on loose thermoelectric powders for the first time. Layer-by-layer construction is realized with bismuth telluride, Bi2Te3, and an 88% relative density was achieved. Scanning electron microscopy results suggest good fusion between each layer although multiple pores exist within the melted region. X-ray diffraction results confirm that the Bi2Te3 crystal structure is preserved after laser melting. Temperature-dependent absolute Seebeck coefficient, electrical conductivity, specific heat, thermal diffusivity, thermal conductivity, and dimensionless thermoelectric figure of merit ZT are characterized up to 500 °C, and the bulk thermoelectric material produced by this technique has comparable thermoelectric and electrical properties to those fabricated from traditional methods. The method shown here may be applicable to other thermoelectric materials and offers a novel manufacturing approach for thermoelectric devices.

Similar content being viewed by others

References

H.J. Goldsmid and R.W. Douglas: The use of semiconductors in thermoelectric refrigeration. Br. J. Appl. Phys. 5, 386 (1954).

G.S. Nolas, J.L. Cohn, G.A. Slack, and S.B. Schujman: Semiconducting Ge clathrates: Promising candidates for thermoelectric applications. Appl. Phys. Lett. 73, 178 (1998).

G.S. Nolas, D.T. Morelli, and T.M. Tritt: Skutterudites: A phonon-glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annu. Rev. Mater. Sci. 29, 89 (1999).

A. Purkayastha, F. Lupo, S. Kim, T. Borca-Tasciuc, and G. Ramanath: Low-temperature, template-free synthesis of single-crystal bismuth telluride nanorods. Adv. Mater. 18, 496 (2006).

M.S. Dresselhaus, G. Chen, M.Y. Tang, R.G. Yang, H. Lee, D.Z. Wang, Z.F. Ren, J-P. Fleurial, and P. Gogna: New directions for low-dimensional thermoelectric materials. Adv. Mater. 19, 1043 (2007).

T.M. Tritt: Thermoelectric phenomena, materials, and applications. Annu. Rev. Mater. Res. 41, 433 (2011).

Y. Tang, R. Hanus, S. Chen, and G.J. Snyder: Solubility design leading to high figure of merit in low-cost Ce–CoSb3 skutterudites. Nat. Commun. 6, 7584 (2015).

M. Beekman, D.T. Morelli, and G.S. Nolas: Better thermoelectrics through glass-like crystals. Nat. Mater. 14, 1182 (2015).

B. Dörling, J.D. Ryan, J.D. Craddock, A. Sorrentino, A. El Basaty, A. Gomez, M. Garriga, E. Pereiro, J.E. Anthony, M.C. Weisenberger, A.R. Goñi, C. Müller, and M. Campoy-Quiles: Photoinduced p- to n-type switching in thermoelectric polymer-carbon nanotube composites. Adv. Mater. 28, 2782 (2016).

C.J.L. Hermes and J.R. Barbosa, Jr.: Thermodynamic comparison of Peltier, Stirling, and vapor compression portable coolers. Appl. Energy 91, 51 (2012).

M.A. Karri, E.F. Thacher, and B.T. Helenbrook: Exhaust energy conversion by thermoelectric generator: Two case studies. Energy Convers. Manage. 52, 1596 (2011).

S. LeBlanc: Thermoelectric generators: Linking material properties and systems engineering for waste heat recovery applications. Sustainable Mater. Technol. 1–2, 26 (2014).

A.F. Ioffe, L.S. Stil’bans, E.K. Iordanishvili, T.S. Stavitskaya, A. Gelbtuch, and G. Vineyard: Semiconductor thermoelements and thermoelectric cooling. Phys. Today 12, 42 (1959).

T.C. Harman, P.J. Taylor, D.L. Spears, and M.P. Walsh: Thermoelectric quantum-dot superlattices with high ZT. J. Electron. Mater. 29, L1 (2000).

R. Venkatasubramanian, E. Siivola, T. Colpitts, and B. O’Quinn: Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413, 597 (2001).

B. Poudel, Q. Hao, Y. Ma, Y. Lan, A. Minnich, B. Yu, X. Yan, D. Wang, A. Muto, D. Vashaee, X. Chen, J. Liu, M.S. Dresselhaus, G. Chen, and Z. Ren: High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634 (2008).

A.I. Hochbaum, R. Chen, R.D. Delgado, W. Liang, E.C. Garnett, M. Najarian, A. Majumdar, and P. Yang: Enhanced thermoelectric performance of rough silicon nanowires. Nature 451, 163 (2008).

G. Zhang, Q. Yu, W. Wang, and X. Li: Nanostructures for thermoelectric applications: Synthesis, growth mechanism, and property studies. Adv. Mater. 22, 1959 (2010).

K. Nielsch, J. Bachmann, J. Kimling, and H. Böttner: Thermoelectric nanostructures: From physical model systems towards nanograined composites. Adv. Energy Mater. 1, 713 (2011).

G. Pennelli: Review of nanostructured devices for thermoelectric applications. Beilstein J. Nanotechnol. 5, 1268 (2014).

C.R. Deckard: U.S. Patent No. US4863538 A, Method and apparatus for producing parts by selective sintering (1986).

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe: Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 57, 133 (2012).

M. Schmid, A. Amado, and K. Wegener: Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 29, 1824 (2014).

A. Zocca, P. Colombo, C.M. Gomes, and J. Günster: Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 98, 1983 (2015).

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, and S.L. Sing: Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2, 041101 (2015).

A. El-Desouky, A.L. Read, P.M. Bardet, M. Andre, and S. Leblanc: Selective laser melting of a bismuth telluride thermoelectric materials. In Proc Solid Free Symp, D. Bourell, ed. (Solid Freeform Fabrication Symposium, Austin, Texas, 2015), pp. 1043–1050.

A. El-Desouky, M. Carter, M.A. Andre, P.M. Bardet, and S. LeBlanc: Rapid processing and assembly of semiconductor thermoelectric materials for energy conversion devices. Mater. Lett. 185, 598 (2016).

A. El-Desouky, M. Carter, M. Mahmoudi, A. Elwany, and S. LeBlanc: Influences of energy density on microstructure and consolidation of selective laser melted bismuth telluride thermoelectric powder. J. Manuf. Process. 25, 411 (2017).

Y. Mao, Y. Yan, K. Wu, H. Xie, Z. Xiu, J. Yang, Q. Zhang, C. Uher, and X. Tang: Non-equilibrium synthesis and characterization of n-type Bi2Te2.7Se0.3 thermoelectric material prepared by rapid laser melting and solidification. RSC Adv. 7, 21439 (2017).

K. Wu, Y. Yan, J. Zhang, Y. Mao, H. Xie, J. Yang, Q. Zhang, C. Uher, and X. Tang: Preparation of n-type Bi2Te3 thermoelectric materials by non-contact dispenser printing combined with selective laser melting. Phys. Status Solidi RRL 11, 1700067 (2017).

Y. Yan, H. Ke, J. Yang, C. Uher, and X. Tang: Fabrication and thermoelectric properties of n-type CoSb2.85Te0.15 using selective laser melting. ACS Appl. Mater. Interfaces 10, 13669 (2018).

F. Kim, B. Kwon, Y. Eom, J.E. Lee, S. Park, S. Jo, S.H. Park, B-S. Kim, H.J. Im, M.H. Lee, T.S. Min, K.T. Kim, H.G. Chae, W.P. King, and J.S. Son: 3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks. Nat. Energy 3, 301 (2018).

H.J. Goldsmid: Bismuth telluride and its alloys as materials for thermoelectric generation. Materials 7, 2577 (2014).

R. Sehr and L.R. Testardi: The optical properties of p-type Bi2Te3–Sb2Te3 alloys between 2–15 microns. J. Phys. Chem. Solids 23, 1219 (1962).

H. Zhang, C-X. Liu, X-L. Qi, X. Dai, Z. Fang, and S-C. Zhang: Topological insulators in Bi2Se3, Bi2Te3, and Sb2Te3 with a single Dirac cone on the surface. Nat. Phys. 5, 438 (2009).

J. Martin, S. Erickson, G.S. Nolas, P. Alboni, T.M. Tritt, and J. Yang: Structural and transport properties of Ba8Ga16SixGe30−x clathrates. J. Appl. Phys. 99, 044903 (2006).

J. Martin and G.S. Nolas: Apparatus for the measurement of electrical resistivity, Seebeck coefficient, and thermal conductivity of thermoelectric materials between 300 K and 12 K. Rev. Sci. Instrum. 87, 015105 (2016).

H.C.H. Ho, I. Gilbson, and W.L. Cheung: Effects of energy density on morphology and properties of selective laser sintered polycarbonate. J. Mater. Process. Technol. 89–90, 204 (1999).

J. Wilkes, Y. Hagedorn, W. Meiners, and K. Wissenbach: Additive manufacturing of ZrO2–Al2O3 ceramic components by selective laser melting. Rapid Prototyp. J. 19, 51 (2013).

P. Bertrand, F. Bayle, C. Combe, P. Goeuriot, and I. Smurov: Ceramic components manufacturing by selective laser sintering. Appl. Surf. Sci. 254, 989 (2007).

L.X. Liu, I. Marziano, A.C. Bentham, J.D. Litster, E.T. White, and T. Howes: Effect of particle properties on the flowability of ibuprofen powders. Int. J. Pharm. 362, 109 (2008).

N. Batista, A. El-Desouky, J. Crandall, S. Wang, J. Yang, and S. LeBlanc: Informatics, Electron. Microsystems (TechConnect Briefs, Washington, District of Columbia, 2017); pp. 166–169.

W.M. Haynes: CRC Handbook of Chemistry and Physics, 95th ed. (CRC Press, Boca Raton, FL, 2014); pp. 4–52.

K. Kempen, L. Thijs, E. Yasa, M. Badrossamay, W. Verheecke, and J-P. Kruth: Process optimization and microstructural analysis for selective laser melting of AlSi10Mg. Solid Freeform Fabr. Symp. Proc. 22, 484 (2011).

K. Monroy, J. Delgado, and J. Ciurana: Study of the pore formation on CoCrMo alloys by selective laser melting manufacturing process. Procedia Eng. 63, 361 (2013).

S. Katayama, Y. Kawahito, and M. Mizutani: Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Procedia 5, 9 (2010).

J.Y. Lee, S.H. Ko, D.F. Farson, and C.D. Yoo: Mechanism of keyhole formation and stability in stationary laser welding. J. Phys. D: Appl. Phys. 35, 1570 (2002).

C.B. Satterthwaite and R.W. Ure: Electrical and thermal properties of Bi2Te3. Phys. Rev. 108, 1164 (1957).

L.D. Zhao, B-P. Zhang, J-F. Li, H.L. Zhang, and W.S. Liu: Enhanced thermoelectric and mechanical properties in textured n-type Bi2Te3 prepared by spark plasma sintering. Solid State Sci. 10, 651 (2008).

M. Saleemi, M.S. Toprak, S. Li, M. Johnsson, M. Muhammed, G. Chen, C. Gatti, Y. Zhang, M. Rowe, M. Muhammed, X.Y. Chen, J.M. Liu, M.S. Dresselhaus, G. Chen, and Z.F. Ren: Synthesis, processing, and thermoelectric properties of bulk nanostructured bismuth telluride (Bi2Te3). J. Mater. Chem. 22, 725 (2012).

C. Euvananont, N. Jantaping, and C. Thanachayanont: Effects of composition and preferred orientation on microstructure and thermoelectric properties of p-type (BixSb(1−x))2Te3 alloys. Curr. Appl. Phys. 11, S246 (2011).

H.J. Goldsmid: The electrical conductivity and thermoelectric power of bismuth telluride. Proc. Phys. Soc. 71, 633 (1958).

H. Zou, D.M. Rowe, and G. Min: Growth of p- and n-type bismuth telluride thin films by co-evaporation. J. Cryst. Growth 222, 82 (2001).

L.M. Goncalves, P. Alpuim, G. Min, D.M. Rowe, C. Couto, and J.H. Correia: Optimization of Bi2Te3 and Sb2Te3 thin films deposited by co-evaporation on polyimide for thermoelectric applications. Vacuum 82, 1499 (2008).

J-H. Kim, J-Y. Choi, J-M. Bae, M-Y. Kim, and T-S. Oh: Thermoelectric characteristics of n-type Bi2Te3 and p-type Sb2Te3 thin films prepared by co-evaporation and annealing for thermopile sensor applications. Mater. Trans. 54, 618 (2013).

F.I. Vasenin: Termoelektricheskie svoistva splavov sistemy vismut-tellur. Zh. Tekh. Fiz. 25, 397 (1955).

L. Ainsworth: Single crystal bismuth telluride. Proc. Phys. Soc., London, Sect. B 69, 606 (1956).

G.S. Nolas, J. Sharp, and H.J. Goldsmid: Thermoelectrics: Basic Principles and New Materials Developments (Springer-Verlag Berlin Heidelberg, Berlin, Germany, 2001).

J.M. Schultz, J.P. McHugh, and W.A. Tiller: Effects of heavy deformation and annealing on the electrical properties of Bi2Te3. J. Appl. Phys. 33, 2443 (1962).

W.R. George, R. Sharples, and J.E. Thompson: The sintering of bismuth telluride. Proc. Phys. Soc. 74, 768 (1959).

R.G. Bernard: Processes involved in sintering. Powder Metall. 2, 86 (1959).

G.R. Miller and C-Y. Li: Evidence for the existence of antistructure defects in bismuth telluride by density measurements. J. Phys. Chem. Solids 26, 173 (1965).

J. Horák, K. Čermák, and L. Koudelka: Energy formation of antisite defects in doped Sb2Te3 and Bi2Te3 crystals. J. Phys. Chem. Solids 47, 805 (1986).

J. Horák, J. Navrátil, and Z. Starý: Lattice point defects and free-carrier concentration in Bi2+ xTe3 and Bi2+ xSe3 crystals. J. Phys. Chem. Solids 53, 1067 (1992).

P. Lošt’ák, Č. Drašar, D. Bachan, L. Beneš, and A. Krejčová: Defects in Bi2Te3−xSex single crystals. Radiat. Eff. Defects Solids 165, 211 (2010).

J. Bludská, I. Jakubec, Č. Drašar, P. Lošťák, and J. Horák: Structural defects in Cu-doped Bi2Te3 single crystals. Philos. Mag. 87, 325 (2007).

C. Drasar, P. Lostak, and C. Uher: Doping and defect structure of tetradymite-type crystals. J. Electron. Mater. 39, 2162 (2010).

A. Hashibon and C. Elsässer: First-principles density functional theory study of native point defects in Bi2Te3. Phys. Rev. B 84, 144117 (2011).

D-H. Kim and G-H. Lee: Effect of rapid thermal annealing on thermoelectric properties of bismuth telluride films grown by co-sputtering. Mater. Sci. Eng., B 131, 106 (2006).

D.A. Wright: Thermoelectric properties of bismuth telluride and its alloys. Nature 181, 834 (1958).

ACKNOWLEDGMENTS

We would like to acknowledge support from Oak Ridge National Laboratory Manufacturing Demonstration Facility RAMP-UP (Subcontract 4000145175), Virginia Center for Innovative Technology (CRCF Award MF16-020-En), and GWU University Facilitating Fund. We are especially grateful to James Ridenour and Dr. Christopher L. Cahill for equipment use and assistance with the XRD work, and we wish to acknowledge Linseis Inc. for the assistance of characterization of thermal and electrical properties. G.S.N. acknowledges support from the National Science Foundation Grant No. DMR-1748188. D.H. acknowledges support from the II-VI Foundation Block-Gift Program. Electron microscopy was conducted in The George Washington University Nanofabrication and Imaging Center.

Author information

Authors and Affiliations

Corresponding authors

Supplementary Material

Rights and permissions

About this article

Cite this article

Zhang, H., Hobbis, D., Nolas, G.S. et al. Laser additive manufacturing of powdered bismuth telluride. Journal of Materials Research 33, 4031–4039 (2018). https://doi.org/10.1557/jmr.2018.390

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.390