Abstract

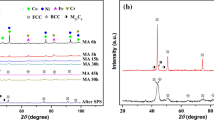

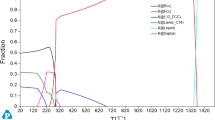

The influence of heat treatment (homogenization) on the microstructure, mechanical behavior, and soft magnetic properties of a face-centered cubic (fcc)-based high-entropy alloy (HEA), Fe29Co28Ni29Cu7Ti7, fabricated by casting, was investigated in detail. The as-cast Fe29Co28Ni29Cu7Ti7 HEA was composed of a primary fcc phase containing coherent dispersed L12 nanoprecipitates and trace amounts of a needle-like phase. The tensile yield strength (σ0.2), ultimate strength, and total elongation of the as-cast alloy are 917 MPa, 1060 MPa, and 1.8%, respectively. Following homogenization, the alloy having a single fcc phase shows a decrease of ∼ 55% in yield strength and a decrease of ∼ 36% in ultimate strength; however, the total elongation is increased from 1.8 to 52%. Saturation magnetization (Msat) is decreased from 111.54 to 110.34 Am2/kg, by contrast, coercivity (Hc) is increased from 266.65 to 966.89 A/m. The dissolution of precipitates and grain growth are mainly responsible for the changes in magnetic properties and mechanical behavior.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

D.B. Miracle and O.N. Senkov: A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448 (2017).

D. Choudhuri, B. Gwalani, S. Gorsse, C.V. Mikler, R.V. Ramanujan, M.A. Gibson, and R. Banerjee: Change in the primary solidification phase from fcc to bcc-based B2 in high entropy or complex concentrated alloys. Scr. Mater. 127, 186 (2017).

Y. Yuan, Y. Wu, X. Tong, H. Zhang, H. Wang, X.J. Liu, L. Ma, H.L. Suo, and Z.P. Lu: Rare-earth high-entropy alloys with giant magnetocaloric effect. Acta Mater. 125, 481 (2017).

Y. Zou, S. Maiti, W. Steurer, and R. Spolenak: Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 65, 85 (2014).

M. Chuang, M. Tsai, W. Wang, S. Lin, and J. Yeh: Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 59, 6308 (2011).

D.H. Lee, M.Y. Seok, Y. Zhao, I.C. Choi, J. He, Z. Lu, J.Y. Suh, U. Ramamurty, M. Kawasaki, T.G. Langdon, and J-i. Jang: Spherical nanoindentation creep behavior of nanocrystalline and coarse-grained CoCrFeMnNi high-entropy alloys. Acta Mater. 109, 314 (2016).

Y. Zhang, T. Zuo, Y. Cheng, and P.K. Liaw: High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 3, 1455 (2013).

C.D. Gómez-Esparza, F.J. Baldenebro-López, C.R. Santillán-Rodríguez, I. Estrada-Guel, J.A. Matutes-Aquino, J.M. Herrera-Ramírez, and R. Martínez-Sánchez: Microstructural and magnetic behavior of an equiatomic NiCoAlFe alloy prepared by mechanical alloying. J. Alloys Compd. 615, S317 (2014).

P. Li, A. Wang, and C.T. Liu: A ductile high entropy alloy with attractive magnetic properties. J. Alloys Compd. 694, 55 (2017).

T. Zuo, M.C. Gao, L. Ouyang, X. Yang, Y. Cheng, R. Feng, S. Chen, P.K. Liaw, J.A. Hawk, and Y. Zhang: Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping. Acta Mater. 130, 10 (2017).

C. Shang, E. Axinte, W. Ge, Z. Zhang, and Y. Wang: High-entropy alloy coatings with excellent mechanical, corrosion resistance and magnetic properties prepared by mechanical alloying and hot pressing sintering. Surf. Interfaces. 9, 36 (2017).

T. Borkar, B. Gwalani, D. Choudhuri, C.V. Mikler, C.J. Yannetta, X. Chen, R.V. Ramanujan, M.J. Styles, M.A. Gibson, and R. Banerjee: A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties. Acta Mater. 116, 63 (2016).

V.M. Nadutov, S.Y. Makarenko, and Y.O. Svystunov: Effect of Al content on magnetic properties and thermal expansion of as-cast high-entropy alloys AlxFeCoNiCuCr. Metallofiz. Noveishie Tekhnol. 37, 987 (2015).

T.T. Zuo, S.B. Ren, P.K. Liaw, and Y. Zhang: Processing effects on the magnetic and mechanical properties of FeCoNiAl0.2Si0.2 high entropy alloy. Int. J. Miner. Metall. Mater. 20, 549 (2013).

P.C. Lin, C.Y. Cheng, J.W. Yeh, and T.S. Chin: Soft magnetic properties of high-entropy Fe–Co–Ni–Cr–Al–Si thin films. Entropy. 18, 1 (2016).

P.F. Yu, L.J. Zhang, H. Cheng, H. Zhang, M.Z. Ma, Y.C. Li, G. Li, P.K. Liaw, and R.P. Liu: The high-entropy alloys with high hardness and soft magnetic property prepared by mechanical alloying and high-pressure sintering. Intermetallics. 70, 82 (2016).

T. Zuo, X. Yang, P.K. Liaw, and Y. Zhang: Influence of bridgman solidification on microstructures and magnetic behaviors of a non-equiatomic FeCoNiAlSi high-entropy alloy. Intermetallics 67, 171 (2015).

S. Singh, N. Wanderka, K. Kiefer, K. Siemensmeyer, and J. Banhart: Effect of decomposition of the Cr–Fe–Co rich phase of AlCoCrCuFeNi high entropy alloy on magnetic properties. Ultramicroscopy 111, 619 (2011).

S. Guo and C.T. Liu: Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci.: Mater. Int. 21, 433 (2011).

X. Yang and Y. Zhang: Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132, 233 (2012).

Z. Fu, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou, and E.J. Lavernia: Microstructure and strengthening mechanisms in an fcc structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 107, 59 (2016).

Z. Fu, B.E. MacDonald, D. Zhang, B. Wu, W. Chen, J. Ivanisenko, H. Hahn, and E.J. Lavernia: Fcc nanostructured TiFeCoNi alloy with multi-scale grains and enhanced plasticity. Scr. Mater. 143, 108 (2018).

I.S. Kim, B.G. Choi, H.U. Hong, J. Do, and C.Y. Jo: Influence of thermal exposure on the microstructural evolution and mechanical properties of a wrought Ni-base superalloy. Mater. Sci. Eng. A. 593, 55 (2014).

L. Xu, C. Cui, and X. Sun: The effects of Co and Ti additions on microstructures and compressive strength of Udimet710. Mater. Sci. Eng. A. 528, 7851 (2011).

A. Takeuchi and A. Inoue: Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 46, 2817 (2005).

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu: Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 116, 332 (2016).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu: Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 62, 105 (2014).

R. Wei, H. Sun, C. Chen, Z. Han, and F. Li: Effect of cooling rate on the phase structure and magnetic properties of Fe26.7Co28.5Ni28.5Si4.6B8.7P3 high entropy alloy. J. Magn. Magn. Mater. 435, 184 (2017).

R.H. Yu, S. Basu, Y.F. Li, Y. Zhang, G.C. Hadjipanayis, B.E. Lorenz, and Q. Xiao: Microstructural effect of magnetic properties of FeCo-based soft magnetic alloys. J. Magn. Soc. Jpn. 23, 397 (1999).

C. Hou, Y. Shan, H. Wu, and X. Bi: Effect of a small addition of Cr on soft magnetic and mechanical properties of Fe–49Co–2V alloy. J. Alloys Compd. 556, 51 (2013).

ACKNOWLEDGMENTS

The authors acknowledge the financial support from the Opening Project of Guangdong Key Laboratory for Advanced Metallic Materials processing, South China University of Technology (GJ201601) and from the US Army Research Office (W911NF-16-1-0269), and Alexander von Humboldt Research Award for Senior Researchers. We would also like to thank Robert E. Delaney for his assistance with magnetic data analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Fu, Z., MacDonald, B.E., Monson, T.C. et al. Influence of heat treatment on microstructure, mechanical behavior, and soft magnetic properties in an fcc-based Fe29Co28Ni29Cu7Ti7 high-entropy alloy. Journal of Materials Research 33, 2214–2222 (2018). https://doi.org/10.1557/jmr.2018.161

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.161