Abstract

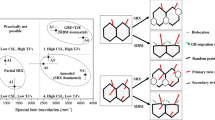

The three-dimensional microstructures of two conventional 316L stainless steels and a grain boundary (GB)-engineered version of the same steel have been characterized by using serial sectioning and electron backscatter diffraction mapping. The morphologies, area fractions, and number fractions of twin boundaries (TBs) were measured and compared, and the random boundary connectivity was evaluated. Although two-dimensional observations suggest that TBs are planar, occluded twin-grains and tunnel-shaped TBs were also observed. In addition, some large and morphologically complex TBs were observed in the GB-engineered sample, and these TBs were responsible for the increase in the twin area fraction that has been reported in past studies. While GB engineering increased the boundary area fraction, the TB number fraction was almost unchanged. Because the GB engineering process changed only the area fraction and not the number fraction, the connectivity of random boundaries was not disrupted.

Similar content being viewed by others

References

H.C.H. Carpenter and S. Tamura: The formation of twinned metallic crystals. Proc. R. Soc. London 113, 161 (1926).

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath: Formation of annealing twins in f.c.c. crystals. Acta Mater. 45, 2633 (1997).

H. Li, S. Xia, B. Zhou, W. Chen, and C. Hu: The dependence of carbide morphology on grain boundary character in the highly twinned alloy 690. J. Nucl. Mater. 399, 108 (2010).

P. Lin, G. Palumbo, U. Erb, and K.T. Aust: Influence of grain boundary character distribution on sensitization and intergranular corrosion of alloy 600. Scr. Metall. Mater. 33, 1387 (1995).

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato, and K. Sakai: Twin-induced grain boundary engineering for 316 austenitic stainless steel. Acta Mater. 54, 5179 (2006).

L. Tan, T.R. Allen, and J.T. Busby: Grain boundary engineering for structure materials of nuclear reactors. J. Nucl. Mater. 441, 661 (2013).

C.L. Hu, S. Xi, H. Li, T.G. Liu, B.X. Zhou, W.J. Chen, and N. Wang: Improving the intergranular corrosion resistance of 304 stainless steel by grain boundary network control. Corros. Sci. 53, 1880 (2011).

S. Xia, H. Li, T.G. Liu, and B.X. Zhou: Appling grain boundary engineering to alloy 690 tube for enhancing intergranular corrosion resistance. J. Nucl. Mater. 416, 303 (2011).

E.A. West and G.S. Was: IGSCC of grain boundary engineered 316L and 690 in supercritical water. J. Nucl. Mater. 392, 264 (2009).

V.Y. Gertsman and S.M. Bruemmer: Study of grain boundary character along intergranular stress corrosion crack paths in austenitic alloys. Acta Mater. 49, 1589 (2001).

D.L. Engelberg, T.J. Marrow, R.C. Newman, and L. Babouta: Grain boundary engineering for crack bridging: A new model for intergranular stress corrosion crack (IGSCC) propagation. In Environment-Induced Cracking of Materials, S.A. Shipilov, R.H. Jones, J.-M. Olive, and R.B. Rebak, eds. (Elsevier, Amsterdam, Netherlands, 2008); pp. 69–79.

T. Watanabe: Approch to grain boundary design for strong and ductile polycrystals. Res Mech. 11, 47 (1984).

T.G. Liu, S. Xia, H. Li, B.X. Zhou, Q. Bai, C. Su, and Z.G. Cai: Effect of initial grain sizes on the grain boundary network during grain boundary engineering in alloy 690. J. Mater. Res. 28, 1165 (2013).

T.G. Liu, S. Xia, H. Li, B.X. Zhou, and Q. Bai: Effect of the pre-existing carbides on the grain boundary network during grain boundary engineering in a nickel based alloy. Mater. Charact. 91, 89 (2014).

V. Randle and M. Coleman: A study of low-strain and medium-strain grain boundary engineering. Acta Mater. 57, 3410–3421 (2009).

V. Randle: Mechanism of twinning-induced grain boundary engineering in low stacking-fault energy materials. Acta Mater. 47, 4187 (1999).

S. Kobayashi, R. Kobayashi, and T. Watanabe: Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 102, 397 (2016).

X. Wang, A. Dallemagne, Y. Hou, and S. Yang: Effect of thermomechanical processing on grain boundary character distribution of Hastelloy X alloy. Mater. Sci. Eng., A 669, 95 (2016).

S. Xia, B.X. Zhou, and W.J. Chen: Grain cluster microstructure and grain boundary character distribution in alloy 690. Metall. Mater. Trans. A 40, 3016 (2009).

W. Cao, S. Xia, Q. Bai, W. Zhang, B. Zhou, Z. Li, and L. Jiang: Effects of initial microstructure on the grain boundary network during grain boundary engineering in Hastelloy N alloy. J. Alloys Compd. 704, 724 (2017).

D.L. Engelberg, R.C. Newman, and T.J. Marrow: Effect of thermomechanical process history on grain boundary control in an austenitic stainless steel. Scripta Mater. 59, 554 (2008).

S.S. Katnagallu, S. Mandal, A.C. Nagaraja, B. De Boer, and S.S. Vadlamani: Role of carbide precipitates and process parameters on achieving grain boundary engineered microstructure in a Ni-based superalloy. Metall. Mater. Trans. A 46, 4740 (2015).

V.Y. Gertsman and C.H. Henager: Grain boundary junctions in microstructure generated by multiple twinning. Interface Sci. 11, 403 (2003).

T.G. Liu, S. Xia, H. Li, B.X. Zhou, and Q. Bai: The highly twinned grain boundary network formation during grain boundary engineering. Mater. Lett. 133, 97 (2014).

T. Liu, S. Xia, B. Wang, Q. Bai, B. Zhou, and C. Su: Grain orientation statistics of grain-clusters and the propensity of multiple-twinning during grain boundary engineering. Mater. Des. 112, 442 (2016).

J. Lind, S.F. Li, and M. Kumar: Twin related domains in 3D microstructures of conventionally processed and grain boundary engineered materials. Acta Mater. 114, 43 (2016).

C.M. Barr, A.C. Leff, R.W. Demott, R.D. Doherty, and M.L. Taheri: Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater. 144, 281 (2018).

M. Kumar, W.E. King, and A.J. Schwartz: Modifications to the microstructural topology in f.c.c. materials through thermomechanical processing. Acta Mater. 48, 2081 (2000).

G. Palumbo, P.J. King, K.T. Aust, U. Erb, and P.C. Lichtenberger: Grain boundary design and control for intergranular stress-corrosion resistance. Scr. Metall. Mater. 25, 1775 (1991).

S. Tsurekawa, S. Nakamichi, and T. Watanabe: Correlation of grain boundary connectivity with grain boundary character distribution in austenitic stainless steel. Acta Mater. 54, 3617 (2006).

S. Tokita, H. Kokawa, Y.S. Sato, and H.T. Fujii: In situ EBSD observation of grain boundary character distribution evolution during thermomechanical process used for grain boundary engineering of 304 austenitic stainless steel. Mater. Charact. 131, 31 (2017).

M. Frary and C.A. Schuh: Connectivity and percolation behaviour of grain boundary networks in three dimensions. Philos. Mag. 85, 1123 (2005).

T. Liu, S. Xia, B. Zhou, Q. Bai, and G.S. Rohrer: Three-dimensional characteristics of the grain boundary networks of conventional and grain boundary engineered 316L stainless steel. Mater. Charact. 133, 60 (2017).

M.A. Meyers and L.E. Murr: A model for the formation of annealing twins in F.C.C. metals and alloys. Acta Metall. 26, 951 (1978).

J. Bystrzycki and W. Przetakiewicz: 3-Dimensional reconstruction of annealing twins shape in FCC metals by serial sectioning. Scr. Metall. Mater. 27, 893 (1992).

A. Telang, A.S. Gill, M. Kumar, S. Teysseyre, D. Qian, S.R. Mannava, and V.K. Vasudevan: Iterative thermomechanical processing of alloy 600 for improved resistance to corrosion and stress corrosion cracking. Acta Mater. 113, 180 (2016).

M.N. Kelly, K. Glowinski, N.T. Nuhfer, and G.S. Rohrer: The five parameter grain boundary character distribution of α-Ti determined from three-dimensional orientation data. Acta Mater. 111, 22 (2016).

J. Konrad, S. Zaefferer, and D. Raabe: Investigation of orientation gradients around a hard Laves particle in a warm-rolled Fe3Al-based alloy using a 3D EBSD-FIB technique. Acta Mater. 54, 1369 (2006).

M.D. Uchic, M.A. Groeber, D.M. Dimiduk, and J.P. Simmons: 3D microstructural characterization of nickel superalloys via serial-sectioning using a dual beam FIB-SEM. Scr. Mater. 55, 23 (2006).

A.C. Lewis, J.F. Bingert, D.J. Rowenhorst, A. Gupta, A.B. Geltmacher, and G. Spanos: Two- and three-dimensional microstructural characterization of a super-austenitic stainless steel. Mat. Sci. Eng., A 418, 11 (2006).

D.J. Rowenhorst, A.C. Lewis, and G. Spanos: Three-dimensional analysis of grain topology and interface curvature in a beta-titanium alloy. Acta Mater. 58, 5511 (2010).

F.X. Lin, A. Godfrey, D.J. Jensen, and G. Winther: 3D EBSD characterization of deformation structures in commercial purity aluminum. Mater. Charact. 61, 1203 (2010).

J.E. Spowart: Automated serial sectioning for 3-D analysis of microstructures. Scr. Mater. 55, 5 (2006).

M. Groeber and M. Jackson: DREAM.3D: A digital representation environment for the analysis of microstructure in 3D. Integr. Mater. Manuf. Innov. 3, 1 (2014).

U. Ayachit: The ParaView Guide: A Parallel Visualization Application (Published by Kitware, Clifton Park, NY, 2015); pp. 1–276.

M. Groeber, S. Ghosh, M.D. Uchic, and D.M. Dimiduk: A framework for automated analysis and simulation of 3D polycrystalline microstructures: Part 1: Statistical characterization. Acta Mater. 56, 1257 (2008).

M. Groeber, S. Ghosh, M. Uchic, and D. Dimiduk: A framework for automated analysis and simulation of 3d polycrystalline microstructures. Part 2: Synthetic structure generation. Acta Mater. 56, 1275 (2008).

Y. Bhandari, S. Sarkar, M. Groeber, M.D. Uchic, D.M. Dimiduk, and S. Ghosh: 3D polycrystalline microstructure reconstruction from FIB generated serial sections for FE analysis. Comput. Mater. Sci. 41, 222 (2007).

D.G. Brandon: The structure of high-angle grain boundaries. Acta Metall. 14, 1479 (1966).

M.A. Armstrong: Basic Topology (Published by Springer, Berlin, 2010); pp. 115–161.

V. Randle: Twinning-related grain boundary engineering. Acta Mater. 52, 4067–4081 (2004).

R.L. Fullman and J.C. Fisher: Formation of annealing twins during grain growth. J. Appl. Phys. 22, 1350 (1951).

S. Dash and N. Brown: An investigation of the origin and growth of annealing twins. Acta Metall. 11, 1067 (1963).

P.J. Goodhew: Annealing twin formation by boundary dissociation. Met. Sci. 13, 108 (1979).

P. Haasen: How are new orientations generated during primary recrystallization?MTA 24, 1001 (1993).

D.P. Field, L.T. Bradford, M.M. Nowell, and T.M. Lillo: The role of annealing twins during recrystallization of Cu. Acta Mater. 55, 4233 (2007).

H. Gleiter: The formation of annealing twins. Acta Metall. 17, 1421 (1969).

G. Gottstein: Annealing texture development by multiple twinning in f.c.c. crystals. Acta Metall. 32, 1117 (1984).

B.W. Reed and M. Kumar: Mathematical methods for analyzing highly-twinned grain boundary networks. Scr. Mater. 54, 1029 (2006).

C. Cayron: Quantification of multiple twinning in face centred cubic materials. Acta Mater. 59, 252 (2011).

K. Deepak, S. Mandal, C.N. Athreya, D-I. Kim, B.d. Boer, and V. Subramanya Sarma: Implication of grain boundary engineering on high temperature hot corrosion of alloy 617. Corros. Sci. 106, 293 (2016).

V. Randle and R. Jones: Grain boundary plane distributions and single-step versus multiple-step grain boundary engineering. Mater. Sci. Eng., A 524, 134 (2009).

L. Tan, K. Sridharan, and T.R. Allen: Effect of thermomechanical processing on grain boundary character distribution of a Ni-based superalloy. J. Nucl. Mater. 371, 171 (2007).

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato, and I. Karibe: Optimization of grain boundary character distribution for intergranular corrosion resistant 304 stainless steel by twin-induced grain boundary engineering. Acta Mater. 50, 2331 (2002).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51671122 and 51701017) and the Fund of Jiangsu Province for the Transformation of Scientific and Technological Achievements (BA2017126).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Liu, T., Xia, S., Zhou, B. et al. Three-dimensional study of twin boundaries in conventional and grain boundary-engineered 316L stainless steels. Journal of Materials Research 33, 1742–1754 (2018). https://doi.org/10.1557/jmr.2018.133

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.133