Abstract

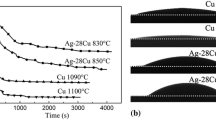

The wetting of Cu-19Ni-5Al alloy on Ni-coated WC-8Co substrates with different coating thicknesses was investigated, and the brazing of Ni-coated WC-8Co to SAE1045 steel was performed by using the Cu-19Ni-5Al alloy as the filler metal. All the Cu-19Ni-5Al/Ni-coated WC-8Co systems present excellent wettability with a final contact angle of ∼10°. The thicknesses of the β + γ phase enriched with Co, Ni, and Al at the two joint interfaces increase and decrease with the Ni coating thickness, brazing temperature, and holding time increasing, respectively. The joint shear strength increases first and then decreases with the increase of Ni coating thickness, brazing temperature, or holding time. The maximum joint shear strength of ∼328 MPa is obtained while Ni plating for 90 min and brazing at 1210 °C × 5 min.

Similar content being viewed by others

References

G.S. Upadhyaya: Materials science of cemented carbides—An overview. Mater. Des. 22, 483 (2001).

X.H. Qu, J.X. Gao, M.L. Qin, and C.M. Lei: Application of a wax-based binder in PIM of WC–TiC–Co cemented carbides. Int. J. Refract. Met. Hard Mater. 23, 273 (2005).

J. Yong and C. Ding: Effect of cryogenic treatment on WC–8Co cemented carbides. Mater. Sci. Eng., A 528, 1735 (2011).

W.B. Lee, B.D. Kwon, and S.B. Jung: Effect of bonding time on joint properties of vacuum brazed WC–8Co hard metal/carbon steel using stacked Cu and Ni alloy as insert metal. Mater. Sci. Technol. 20, 1474 (2004).

W.B. Lee, B.D. Kwon, and S.B. Jung: Effects of Cr3C2 on the microstructure and mechanical properties of the brazed joints between WC–8Co and carbon steel. Int. J. Refract. Met. Hard Mater. 24, 215 (2006).

H.S. Chen, K.Q. Feng, S.F. Wei, J. Xiong, Z.X. Guo, and H. Wang: Microstructure and properties of WC–Co/3Cr13 joints brazed using Ni electroplated interlayer. Int. J. Refract. Met. Hard Mater. 33, 70 (2012).

M. Uzkut, N.S. Koksal, and B.S. Unlu: The determination of element diffusion in connecting SAE 1040/WC material by brazing. J. Mater. Process. Technol. 169, 409 (2005).

Y.W. Sui, H.B. Luo, Y. Lv, F.X. Wei, J.Q. Qi, and Y.Z. He: Influence of brazing technology on the microstructure and properties of YG20C cemented carbide and 16Mn steel joints. Weld. World 60, 1269 (2016).

C. Jiang, H. Chen, Q.Y. Wang, and Y.X. Li: Effect of brazing temperature and holding time on joint properties of induction brazed WC–8Co/carbon steel using Ag–based alloys. J. Mater. Process. Technol. 229, 562 (2016).

M.I. Barrena, J.M.G. de Salazar, and M. Gomez-Vacas: Numerical simulation and experimental analysis of vacuum brazing for steel/cermet. Ceram. Int. 40, 10557 (2014).

X.Z. Zhang, G.W. Liu, J.N. Tao, H.C. Shao, H. Fu, T.Z. Pan, and G.J. Qiao: Vacuum brazing of WC–8Co cemented carbides to carbon steel using pure Cu and Ag–28Cu as filler metal. J. Mater. Eng. Perform. 26, 488 (2017).

L. Zhu, L.M. Luo, J. Luo, Y.C. Wu, and J. Li: Effect of electroless plating Ni–Cu–P layer on brazability of cemented carbide to steel. Surf. Coat. Technol. 206, 2521 (2012).

T. Iamboliev, S. Valkanov, and S. Atanasova: Microstructure embrittlement of hard metal–steel joint obtained under induction heating diffusion bonding. Int. J. Refract. Met. Hard Mater. 37, 90 (2013).

K.Q. Feng, H.S. Chen, J. Xiong, and Z.X. Guo: Investigation on diffusion bonding of functionally graded WC–8Co/Ni composite and stainless steel. Mater. Des. 46, 622 (2013).

M.I. Barrena, J.M.G. de Salazar, and L. Matesanz: Interfacial microstructure and mechanical strength of WC–8Co/90MnCrV8 cold work tool steel diffusion bonded joint with Cu/Ni electroplated interlayer. Mater. Des. 31, 3389 (2010).

M.I. Barrena, J.M. Gomez de Salazar, and L. Matesanz: Ni–Cu alloy for diffusion bonding cermet/steel in air. Mater. Lett. 63, 2142 (2009).

Y.J. Guo, Y.Q. Wang, B.X. Gao, Z.Q. Shi, and Z.W. Yuan: Rapid diffusion bonding of WC–Co cemented carbide to 40Cr steel with Ni interlayer: Effect of surface roughness and interlayer thickness. Ceram. Int. 42, 16729 (2016).

P.Q. Xu, J.W. Ren, P.L. Zhang, H.Y. Gong, and S.L. Yang: Analysis of formation and interfacial WC dissolution behavior of WC–8Co/invar laser–TIG welded joints. J. Mater. Eng. Perform. 22, 613 (2013).

D.R. Zhou, H.C. Cui, P.Q. Xu, and F.G. Lu: Tungsten carbide grain size computation for WC–Co dissimilar welds. J. Mater. Eng. Perform. 25, 2500 (2016).

Y.G. Guo, B.X. Gao, G.W. Liu, T.T. Zhou, and G.J. Qiao: Effect of temperature on the microstructure and bonding strength of partial transient liquid phase bonded WC–8Co/40Cr joints using Ti/Ni/Ti interlayers. Int. J. Refract. Met. Hard Mater. 51, 250 (2015).

G.W. Liu, F. Valenza, M.L. Muolo, G.J. Qiao, and A. Passerone: Wetting and interfacial behavior of Ni–Si alloy on different substrates. J. Mater. Sci. 44, 5990 (2009).

G.W. Liu, F. Valenza, M.L. Muolo, and A. Passerone: SiC/SiC and SiC/Kovar joining by Ni–Si and Mo interlayers. J. Mater. Sci. 45, 4299 (2010).

G.W. Liu, G.J. Qiao, H.J. Wang, J.F. Yang, and T.J. Lu: Pressureless brazing of zirconia to stainless steel with Ag–Cu filler metal and TiH2 powder. J. Eur. Ceram. Soc. 28, 2701 (2008).

Y. Sechi, T. Tsumura, and K. Nakata: Dissimilar laser brazing of boron nitride and tungsten carbide. Mater. Des. 31, 2071 (2010).

V.L. Silva, C.M. Fernandes, and A.M.R. Senos: Copper wettability on tungsten carbide surfaces. Ceram. Int. 42, 1191 (2016).

Z. Mirski and T. Piwowarczyk: Wettability of hardmetal surfaces prepared for brazing with various methods. Arch. Civ. Mech. Eng. 11, 411 (2011).

R. Kainuma, M. Ise, C.C. Jia, H. Ohtani, and K. Ishida: Phase equilibria and microstructural control in the Ni–Co–Al system. Intermetallics 4, 151 (1996).

J. Liu and J.G. Li: Microstructure, microstructure, shape memory effect and mechanical properties of rapidly solidified Co–Ni–Al magnetic shape memory alloys. Mater. Sci. Eng., A 454–455, 423 (2007).

K. Ishida, R. Kainuma, U. Ueno, and T. Nishizawa: Ductility enhancement in NiAl (B2)-base alloys by microstructural control. Metall. Trans. A 22, 441 (1991).

N. Eustathopoulos: Progress in understanding and modeling reactive wetting of metals on ceramics. Curr. Opin. Solid State Mater. Sci. 9, 152 (2005).

N. Eustathopoulos: Wetting by liquid metals—Application in materials processing: The contribution of the grenoble group. Metals 5, 350 (2015).

E. Saiz, A.P. Tomsia, and R.M. Cannon: Ridging effects on wetting and spreading of liquids on solids. Acta Mater. 46, 2349 (1998).

E. Saiz, R.M. Cannon, and A.P. Tomsia: Reactive spreading: Adsorption, ridging and compound formation. Acta Mater. 48, 4449 (2000).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (51572112); the Natural Science Foundation of Jiangsu Province (BK20151340); the Six Talent Peaks Project of Jiangsu Province (2014-XCL-002, TD-XCL-004); the 333 talents project of Jiangsu province (BRA2017387); and the Innovation/Entrepreneurship Program of Jiangsu Province ([2015]26) and the Qing Lan Project ([2016]15).

Author information

Authors and Affiliations

Corresponding authors

Supplementary Material

43578_2018_33111671_MOESM1_ESM.doc

Supporting Information: Wetting and brazing of Ni-coated WC-8Co cemented carbide using Cu-19Ni-5Al alloy as filler metal: Microstructural evolution and joint mechanical properties (approximately 34 KB)

Rights and permissions

About this article

Cite this article

Zhang, X., Huang, Z., Liu, G. et al. Wetting and brazing of Ni-coated WC-8Co cemented carbide using the Cu-19Ni-5Al alloy as the filler metal: Microstructural evolution and joint mechanical properties. Journal of Materials Research 33, 1671–1680 (2018). https://doi.org/10.1557/jmr.2018.101

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.101