Abstract

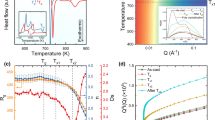

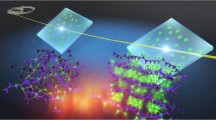

Bragg coherent X-ray diffraction imaging has been used to determine the structure of the initial clusters of α-Fe nano crystals which form upon annealing of an iron-based amorphous alloy or metallic glass. The method is able to identify the shapes and strain of these crystallites without any need for cutting the sample, so can visualize them in three dimensions in their intact state. In this way, the delicate dendritic structures on the exterior of the crystallites can be seen and its density versus radius relationship identifies a fractal dimension of the porous region that is consistent with diffusion-limited aggregation models. The crystal sizes were found to be around 60 nm after annealing at 700 °C growing to about 330 nm after annealing at 750 °C. This article introduces the BCDI method and describes its application to characterize previously recrystallized samples of iron-based amorphous alloys. It paves the way for a possible future in situ nucleation/growth investigation of the relationship between kinetics and nanostructure of metallic glass.

Similar content being viewed by others

References

D. Sayre: Some implications of a theorem due to Shannon. Acta Crystallogr. 5, 843 (1952).

G.J. Williams, M.A. Pfeifer, I.A. Vartanyants, and I.K. Robinson: Internal structure in Au nanocrystals resolved by 3D inversion of coherent X-ray diffraction. Phys. Rev. B: Condens. Matter Mater. Phys. 73, 094112 (2006).

M.A. Pfeifer, G.J. Williams, I.A. Vartanyants, R. Harder, and I.K. Robinson: Three-dimensional mapping of a deformation field inside a nanocrystal. Nature 442, 63–66 (2006).

I.K. Robinson and R. Harder: Coherent diffraction imaging of strains on the nanoscale. Nat. Mater. 8, 291–298 (2009).

W. Klement, R.H. Willens, and P. Duwez: Non-crystalline structure in solidified gold–silicon alloys. Nature 187, 869 (1960).

J. Shen, Q.J. Chen, J.F. Sun, H.B. Fan, and G. Wang: Exceptional high glass-forming ability of an FeCoCrMoCBY alloy. Appl. Phys. Lett. 86, 151907 (2005).

A. Inoue, B.L. Shen, and C.T. Chang: Fe- and Co-based bulk glassy alloys with ultrahigh strength of over 4000 MPa. Intermetallics 14, 936 (2006).

X.J. Gu, S.J. Poon, G.J. Shiflet, and M. Widom: Ductility improvement of amorphous steels: Roles of shear modulus and electronic structure. Acta Mater. 56, 88 (2008).

K.F. Yao and C.Q. Zhang: Fe-based bulk metallic glass with high plasticity. Appl. Phys. Lett. 90, 2005 (2007).

A. Kobayashi, S. Yano, H. Kimura, and A. Inoue: Fe-based metallic glass coatings produced by smart plasma spraying process. Mater. Sci. Eng., B 148, 110 (2008).

X.Q. Liu, Y.G. Zheng, X.C. Chang, W.L. Hou, J.Q. Wang, Z. Tang, and A. Burgess: Microstructure and properties of Fe-based amorphous metallic coating produced by high velocity axial plasma spraying. J. Alloys Compd. 484, 300 (2009).

Y. Huang, Y. Guo, H. Fan, and J. Shen: Synthesis of Fe–Cr–Mo–C–B amorphous coating with high corrosion resistance. Mater. Lett. 89, 251 (2012).

X.L. Wu and Y.S. Hong: Fe-based thick amorphous-alloy coating by laser cladding. Surf. Coat. Technol. 141, 141 (2001).

D. Liu, W. Gao, Z. Li, H. Zhang, and Z. Hu: Electro-spark deposition of Fe-based amorphous alloy coatings. Mater. Lett. 61, 165 (2007).

L. Ajdelsztajn, B. Jodoin, P. Richer, E. Sansoucy, and E.J. Lavernia: Cold gas dynamic spraying of iron-base amorphous alloy. J. Therm. Spray Technol. 15, 495 (2006).

W.D. Liu, K.X. Liu, Q.Y. Chen, J.T. Wang, H.H. Yan, and X.J. Li: Metallic glass coating on metals plate by adjusted explosive welding technique. Appl. Surf. Sci. 255, 9343 (2009).

J.B. Cheng, X.B. Liang, B.S. Xu, and Y.X. Wu: Formation and properties of Fe-based amorphous/nanocrystalline alloy coating prepared by wire arc spraying process. J. Non-Cryst. Solids 355, 1673 (2009).

J.B. Cheng, X.B. Liang, B.S. Xu, and Y.X. Wu: Characterization of mechanical properties of FeCrBSiMnNbY metallic glass coatings. J. Mater. Sci. 44, 3356 (2009).

Y. Wang, Y.G. Zheng, W. Ke, W.H. Sun, W.L. Hou, X.C. Chang, and J.Q. Wang: Slurry erosion-corrosion behaviour of high-velocity oxy-fuel (HVOF) sprayed Fe-based amorphous metallic coatings for marine pump in sand-containing NaCl solutions. Corros. Sci. 53, 3177 (2011).

Z. Zhou, L. Wang, F.C. Wang, H.F. Zhang, Y.B. Liu, and S.H. Xu: Formation and corrosion behavior of Fe-based amorphous metallic coatings by HVOF thermal spraying. Surf. Coat. Technol. 204, 563 (2009).

C. Zhang, Y. Wu, and L. Liu: Robust hydrophobic Fe-based amorphous coating by thermal spraying. Appl. Phys. Lett. 101, 1 (2012).

C. Zhang, L. Liu, K.C. Chan, Q. Chen, and C.Y. Tang: Wear behavior of HVOF-sprayed Fe-based amorphous coatings. Intermetallics 29, 80 (2012).

D.J. Branagan, W.D. Swank, D.C. Haggard, and J.R. Fincke: Wear-resistant amorphous and nanocomposite steel coatings. Metall. Mater. Trans. A 32, 2615 (2001).

Q. Zhu, S. Qu, X. Wang, and Z. Zou: Synthesis of Fe-based amorphous composite coatings with low purity materials by laser cladding. Appl. Surf. Sci. 253, 7060 (2007).

R.Q. Guo, C. Zhang, Q. Chen, Y. Yang, N. Li, and L. Liu: Study of structure and corrosion resistance of Fe-based amorphous coatings prepared by HVAF and HVOF. Corros. Sci. 53, 2351 (2011).

Y. Wang, Z.Z. Xing, Q. Luo, A. Rahman, J. Jiao, S.J. Qu, Y.G. Zheng, and J. Shen: Corrosion and erosion-corrosion behaviour of activated combustion high-velocity air fuel sprayed Fe-based amorphous coatings in chloride-containing solutions. Corros. Sci. 98, 339 (2015).

K. Chokethawai, D.G. McCartney, and P.H. Shipway: Microstructure evolution and thermal stability of an Fe-based amorphous alloy powder and thermally sprayed coatings. J. Alloys Compd. 480, 351 (2009).

Y. Yang, C. Zhang, Y. Peng, Y. Yu, and L. Liu: Effects of crystallization on the corrosion resistance of Fe-based amorphous coatings. Corros. Sci. 59, 10 (2012).

L. Liu and C. Zhang: Fe-based amorphous coatings: Structures and properties. Thin Solid Films 561, 70 (2014).

J.B. Cheng, X.B. Liang, and B.S. Xu: Effects of crystallization on the corrosion resistance of arc-sprayed FeBSiNb coatings. J. Therm. Spray Technol. 23, 373 (2014).

K. Kishitake, H. Era, and F. Otsubo: Thermal-sprayed Fe–10Cr–13P–7C amorphous coatings possessing excellent corrosion resistance. J. Therm. Spray Technol. 5, 494 (1996).

V.A. Blagojevic, D.M. Minic, T. Zak, and D.M. Minic: Influence of thermal treatment on structure and microhardness of Fe75Ni2Si8B13C2 amorphous alloy. Intermetallics 19, 1780 (2011).

R.S. Mishra, S.X. McFadden, R.Z. Valiev, and A.K. Mukherjee: Deformation mechanisms and tensile superplasticity in nanocrystalline materials. JOM 51, 37 (1999).

J.R. Weertman, D. Farkas, K. Hemker, H. Kung, M. Mayo, R. Mitra, and H. Van Swygenhoven: Structure and mechanical behavior of bulk nanocrystalline materials. MRS Bull. 24, 44 (1999).

A.L. Greer: Partially of fully devitrified alloys for mechanical properties. Mater. Sci. Eng., A 304, 68 (2001).

T.A. Witten and L.M. Sander: Diffusion-limited aggregation, a kinetic critical phenomenon. Phys. Rev. Lett. 47, 1400 (1981).

M. Meakin and Z.R. Wasserman: Some universality properties associated with the cluster-cluster aggregation model. Phys. Lett. 103, 337 (1984).

M. Kardar, G. Parisi, and Y.Z. Zhang: Dynamic scaling of growing interfaces. Phys. Rev. Lett. 56, 889 (1986).

S. Chen, H. Wang, G. Ma, J. Kang, and B. Xu: Fractal properties of worn surface of Fe-based alloy coatings during rolling contact process. Appl. Surf. Sci. 364, 96 (2016).

Q. Chang, D.L. Chen, H.Q. Ru, X.Y. Yue, L. Yu, and C.P. Zhang: Three-dimensional fractal analysis of fracture surfaces in titanium–iron particulate reinforced hydroxyapatite composites: Relationship between fracture toughness and fractal dimension. J. Mater. Sci. 46, 6118 (2011).

U. Köster and U. Harold: Glassy Metals I (Springer-Verlag, Berlin, 1981).

M. Monteforte, A.K. Estandarte, B. Chen, R. Harder, M. Huang, and I.K. Robinson: Novel silica stabilisation method for the analysis of fine nanocrystals using coherent X-ray diffraction imaging. J. Synchrotron Radiat. 23, 953 (2016).

J.R. Fienup: Reconstruction of an object from the modulus of its Fourier transform. Opt. Lett. 3, 27 (1978).

J.R. Fienup: Phase retrieval algorithms: A comparison. Appl. Opt. 21, 2758 (1982).

S. Marchesini, H. He, H.N. Chapman, S.P. Hau-Riege, A. Noy, M.R. Howells, U. Weierstall, and J.C.H. Spence: X-ray image reconstruction from a diffraction pattern alone. Phys. Rev. B: Condens. Matter Mater. Phys. 68, 140101 (2003).

C.C. Chen, J. Miao, C.L. Wang, and T.K. Lee: Application of optimization technique to noncrystalline X-ray diffraction microscopy: Guided hybrid input–output method. Phys. Rev. B: Condens. Matter Mater. Phys. 76, 064113 (2007).

K. Lad, M. Maaroof, K.G. Raval, and A. Pratap: Fractal growth kinetics during crystallization of amorphous Cu50Zr50. Prog. Cryst. Growth Charact. Mater. 45, 15 (2002).

ACKNOWLEDGMENTS

This work was supported by the UK Engineering and Physical Sciences Research Council (EPSRC) grant EP/I022562/1 “Phase modulation technology for X-ray imaging”. Work performed at Brookhaven National Laboratory was supported by the US Department of Energy, Office of Basic Energy Sciences, under Contract Number DE-SC00112704. Work at TongJi University was supported by the Talent Program “Materials Nano-structure” with grants 152221 and 152243, National Natural Science Foundation of China grants 51371127 and 51274151 as well as Shanghai Natural Science Foundation grant 13ZR1462400. The experimental work was carried out at Advanced Photon Source Beamline 34-ID-C, built with funds from the US National Science Foundation under Grant DMR-9724294 and operated by the US Department of Energy, Office of Basic Energy Sciences under Contract DE-AC02-06CH11357. We thank Ross Harder and Evan Maxey for assistance with the beamline.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Diao, J., Chen, B., Luo, Q. et al. Nucleation of fractal nanocrystallites upon annealing of Fe-based metallic glass. Journal of Materials Research 32, 1880–1887 (2017). https://doi.org/10.1557/jmr.2017.79

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.79