Abstract

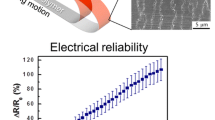

To secure the reliability of flexible electronics, the effect of multicomponent stress on the device properties during complex mechanical deformation needs to be thoroughly understood. The electrical resistances of metal interconnects are investigated by in situ monitoring at different twisting angles and with different pattern positions. As the twisting angle increased, the electrical resistance increased earlier. Furthermore, in the line pattern located far from the central axis, severe electrical degradation and fatigue damage formation were observed. Multicomponent stress evolution during twisting was analyzed by the finite-element simulation method. For easy practical application for estimating the representative twisting strain, an analytic solution of twisting deformation was formulated and compared with the simulation. Using the equivalent strain, the fatigue lifetime was fitted, and the exponents were obtained for lifetime expectation. This systematic study provides the guidelines for highly reliable flexible devices and the tools for determining the expected fatigue lifetime.

Similar content being viewed by others

References

X. Huang, Y. Liu, H. Cheng, W-J. Shin, J.A. Fan, Z. Liu, C-J. Lu, G-W. Kong, K. Chen, D. Patnaik, S-H. Lee, S. Hage-Ali, Y. Huang, and J.A. Rogers: Materials and designs for wireless epidermal sensors of hydration and strain. Adv. Funct. Mater. 24, 3846–3854 (2014).

Q.C. Liu, J.J. Xu, D. Xu, and X.B. Zhang: Flexible lithium-oxygen battery based on a recoverable cathode. Nat. Commun. 6, 7892 (2015).

S. Kim, H.J. Kwon, S. Lee, H. Shim, Y. Chun, W. Choi, J. Kwack, D. Han, M. Song, S. Kim, S. Mohammadi, I. Kee, and S.Y. Lee: Low-power flexible organic light-emitting diode display device. Adv. Mater. 23, 3511–3516 (2011).

Y. Li, D-K. Lee, J.Y. Kim, B. Kim, N-G. Park, K. Kim, J-H. Shin, I-S. Choi, and M.J. Ko: Highly durable and flexible dye-sensitized solar cells fabricated on plastic substrates: PVDF-nanofiber-reinforced TiO2 photoelectrodes. Energy Environ. Sci. 5, 8950 (2012).

X. Zhu, B. Zhang, J. Gao, and G. Zhang: Evaluation of the crack-initiation strain of a Cu–Ni multilayer on a flexible substrate. Scr. Mater. 60, 178–181 (2009).

J-H. Lee, N-R. Kim, B-J. Kim, and Y-C. Joo: Improved mechanical performance of solution-processed MWCNT/Ag nanoparticle composite films with oxygen-pressure-controlled annealing. Carbon 50, 98–106 (2012).

B-J. Kim, H-A.S. Shin, J-H. Lee, T-Y. Yang, T. Haas, P. Gruber, I-S. Choi, O. Kraft, and Y-C. Joo: Effect of film thickness on the stretchability and fatigue resistance of Cu films on polymer substrates. J. Mater. Sci. 29, 2827–2834 (2014).

Y-J. Lee, H-A.S. Shin, D-H. Nam, H-W. Yeon, B. Nam, K. Woo, and Y-C. Joo: Improvements of mechanical fatigue reliability of Cu interconnects on flexible substrates through MoTi alloy under-layer. Electron. Mater. Lett. 11, 149–154 (2015).

O. Glushko, A. Klug, E.J.W. List-Kratochvil, and M.J. Cordill: Relationship between mechanical damage and electrical degradation in polymer-supported metal films subjected to cyclic loading. Mater. Sci. Eng., A 662, 157–161 (2016).

D. Akinwande, N. Petrone, and J. Hone: Two-dimensional flexible nanoelectronics. Nat. Commun. 5, 5678 (2014).

P. Lee, J. Lee, H. Lee, J. Yeo, S. Hong, K.H. Nam, D. Lee, S.S. Lee, and S.H. Ko: Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network. Adv. Mater. 24, 3326–3332 (2012).

B.J. Kim, Y. Cho, M.S. Jung, H.A. Shin, M.W. Moon, H.N. Han, K.T. Nam, Y.C. Joo, and I.S. Choi: Fatigue-free, electrically reliable copper electrode with nanohole array. Small 8, 3300–3306 (2012).

G.D. Moon, G.H. Lim, J.H. Song, M. Shin, T. Yu, B. Lim, and U. Jeong: Highly stretchable patterned gold electrodes made of Au nanosheets. Adv. Mater. 25, 2707–2712 (2013).

Y. Zhang, H. Fu, Y. Su, S. Xu, H. Cheng, J.A. Fan, K-C. Hwang, J.A. Rogers, and Y. Huang: Mechanics of ultra-stretchable self-similar serpentine interconnects. Acta Mater. 61, 7816–7827 (2013).

Y-Y. Hsu, M. Gonzalez, F. Bossuyt, F. Axisa, J. Vanfleteren, and I. De Wolf: The effect of pitch on deformation behavior and the stretching-induced failure of a polymer-encapsulated stretchable circuit. J. Micromech. Microeng. 20, 075036 (2010).

M. Gonzalez, F. Axisa, M.V. Bulcke, D. Brosteaux, B. Vandevelde, and J. Vanfleteren: Design of metal interconnects for stretchable electronic circuits. Microelectron. Reliab. 48, 825–832 (2008).

R. Zhou, W. Guo, R. Yu, and C. Pan: Highly flexible, conductive and catalytic Pt networks as transparent counter electrodes for wearable dye-sensitized solar cells. J. Mater. Chem. A 3, 23028–23034 (2015).

S.G. Yoon, H.J. Koo, and S.T. Chang: Highly stretchable and transparent microfluidic strain sensors for monitoring human body motions. ACS Appl. Mater. Interfaces 7, 27562–27570 (2015).

D-Y. Cho, K. Eun, S-H. Choa, and H-K. Kim: Highly flexible and stretchable carbon nanotube network electrodes prepared by simple brush painting for cost-effective flexible organic solar cells. Carbon 66, 530–538 (2014).

S. Song, J. Jang, Y. Ji, S. Park, T-W. Kim, Y. Song, M-H. Yoon, H.C. Ko, G-Y. Jung, and T. Lee: Twistable nonvolatile organic resistive memory devices. Org. Electron. 14, 2087–2092 (2013).

N. Lu, Z. Suo, and J.J. Vlassak: The effect of film thickness on the failure strain of polymer-supported metal films. Acta Mater. 58, 1679–1687 (2010).

D.Y.W. Yu and F. Spaepen: The yield strength of thin copper films on Kapton. J. Appl. Phys. 95, 2991–2997 (2004).

S. Suresh: Fatigue of Materials, 2nd ed. (Cambridge University Press, Cambridge, 1999); pp. 133–222.

G.E. Dieter: Mechanical Metallurgy (McGraw-Hill Book Company, London, 1988); pp. 381–419.

B-J. Kim, H-A.S. Shin, S-Y. Jung, Y. Cho, O. Kraft, I-S. Choi, and Y-C. Joo: Crack nucleation during mechanical fatigue in thin metal films on flexible substrates. Acta Mater. 61, 3473–3481 (2013).

Y. Li, X-S. Wang, and X-K. Meng: Buckling behavior of metal film/substrate structure under pure bending. Appl. Phys. Lett. 92, 131902–131903 (2008).

F. Toth, F.G. Rammerstorfer, M.J. Cordill, and F.D. Fischer: Detailed modelling of delamination buckling of thin films under global tension. Acta Mater. 61, 2425–2433 (2013).

I.H. Shames and J.M. Pitarresi: Introducion to Solid Mechanics, 3rd ed. (Pearson Education, New Delhi, 2000); pp. 513–554.

R. Gupta and T.S. Siller: Stress distribution in structural composite lumber under torsion. For. Prod. J. 55, 51–56 (2005).

H. Huang and F. Spaepen: Tensile testing of free-standing Cu, Ag, and Al thin films and Ag/Cu multilayers. Acta Mater. 48, 3261–3269 (2000).

Y. Xiang and J.J. Vlassak: Bauschinger effect in thin metal films. Scr. Mater. 53, 177–182 (2005).

N.S. Trahair: Nonlinear elastic nonuniform torsion. J. Struct. Eng. 131, 1135–1142 (2005).

L.F. Coffin: A study of the effects of cyclic thermal stresses on a ductile metal. Trans. ASME. 76, 931–950 (1954).

S.S. Manson: Behavior of Materials Under Conditions of Thermal Stress; Report 1170; Lewis Flight Propulsion Laboratory: Cleveland, OH, 1954.

O. Kraft, R. Schwaiger, and P. Wellner: Fatigue in thin films: Lifetime and damage formation. Mater. Sci. Eng., A 319–321, 919–923 (2001).

X.J. Sun, C.C. Wang, J. Zhang, G. Liu, G.J. Zhang, X.D. Ding, G.P. Zhang, and J. Sun: Thickness dependent fatigue life at microcrack nucleation for metal thin films on flexible substrates. J. Phys. D: Appl. Phys. 41, 195404 (2008).

O.H. Basquin: The exponential law of endurance tests. Proc. ASTM 10, 625–630 (1910).

ACKNOWLEDGMENTS

This research was supported by “Development of Interconnection System and Process for Flexible Three Dimensional Heterogeneous Devices” funded by MOTIE (Ministry of Trade, Industry and Energy) and National Research Foundation of Korea (NRF) grant funded by the Korea Government (MSIP; Ministry of Science, ICT & Future Planning) (No. 2017R1C1B5017889) in Korea.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, JK., Lee, YJ., Yi, SM. et al. Effect of twisting fatigue on the electrical reliability of a metal interconnect on a flexible substrate. Journal of Materials Research 33, 138–148 (2018). https://doi.org/10.1557/jmr.2017.422

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.422