Abstract

Fatigue is one of the major failure modes of structural materials. While the effects of strengthening precipitates on the mechanical properties of heat treatable aluminum alloys during forming operations are well-studied, only little is known about the related mechanisms during fatigue. We study the influence of precipitates during low cycle fatigue of an Al-Si-Mg alloy by mechanical testing and microstructure characterisation using (scanning) transmission electron microscopy. Specifically, we have investigated under-aged, peak-aged, and over-aged precipitation states. The experiments reveal considerable influence of the precipitate state on the mechanical properties and the formed dislocation structures. Under-aged AA6016 experiences cyclic hardening accompanied by dynamic precipitation and precipitate growth during cyclic deformation, whereas peak-aged AA6016 shows a saturated cyclic stress behavior and the formation of a ‘prevein’-like dislocation structure aligned along [001]Al directions. Over-aged AA6016 exhibits cyclic softening, which is assumed to be due to frequent Orowan-looping of dislocations around incoherent precipitates.

Similar content being viewed by others

References

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge: Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng., A 280, 37 (2000).

G.A. Edwards, K. Stiller, G.L. Dunlop, and M.J. Couper: The precipitation sequence in Al–Mg–Si alloys. Acta Mater. 46, 3893 (1998).

C.D. Marioara, S.J. Andersen, J. Jansen, and H.W. Zandbergen: The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al–Mg–Si alloy. Acta Mater. 51, 789 (2003).

H. Mughrabi: Fatigue, an everlasting materials problem-still en vogue. Procedia Eng. 2, 3 (2010).

F.C. Campbell: Elements of Metallurgy and Engineering Alloys (ASM International, Materials Park, Ohio, 2008).

C.R. Hutchinson, F. De Geuser, Y. Chen, and A. Deschamps: Quantitative measurements of dynamic precipitation during fatigue of an Al–Zn–Mg–(Cu) alloy using small-angle X-ray scattering. Acta Mater. 74, 96 (2014).

S. Nandy, A.P. Sekhar, T. Kar, K.K. Ray, and D. Das: Influence of ageing on the low cycle fatigue behaviour of an Al–Mg–Si alloy. Philos. Mag. 97, 1 (2017).

C.S. Tsao, C.Y. Chen, U.S. Jeng, and T.Y. Kuo: Precipitation kinetics and transformation of metastable phases in Al–Mg–Si alloys. Acta Mater. 54, 4621 (2006).

W. Yang, L. Huang, R. Zhang, M. Wang, Z. Li, Y. Jia, R. Lei, and X. Sheng: Electron microscopy studies of the age-hardening behaviors in 6005A alloy and microstructural characterizations of precipitates. J. Alloys Compd. 514, 220 (2012).

M. Torsæter, H.S. Hasting, W. Lefebvre, C.D. Marioara, J.C. Walmsley, S.J. Andersen, and R. Holmestad: The influence of composition and natural aging on clustering during preaging in Al–Mg–Si alloys. J. Appl. Phys. 108, 073527 (2010).

F. De Geuser, W. Lefebvre, and D. Blavette: 3D atom probe study of solute atoms clustering during natural ageing and pre-ageing of an Al–Mg–Si alloy. Philos. Mag. Lett. 86, 227 (2006).

J.D. Bryant: The effects of preaging treatments on aging kinetics and mechanical properties in AA6111 aluminum autobody sheet. Metall. Mater. Trans. A 30 (1999).

S. Pogatscher, H. Antrekowitsch, M. Werinos, F. Moszner, S.S.A. Gerstl, M.F. Francis, W.A. Curtin, J.F. Löffler, and P.J. Uggowitzer: Diffusion on demand to control precipitation aging: Application to Al–Mg–Si alloys. Phys. Rev. Lett. 112, 225701 (2014).

A. Guinier: Structure of age-hardened aluminium–copper alloys. Nature 142, 569 (1938).

G.D. Preston: Structure of age-hardened aluminium–copper alloys. Nature 142, 570 (1938).

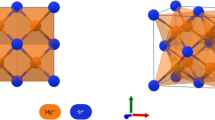

K. Matsuda, T. Naoi, K. Fujii, Y. Uetani, T. Sato, A. Kamio, and S. Ikeno: Crystal structure of the β″ phase in an Al–1.0 mass% Mg2Si–0.4 mass% Si alloy. Mater. Sci. Eng., A 262, 232 (1999).

S.J. Andersen, C.D. Marioara, M. Torsæter, R. Bjørge, F.J.H. Ehlers, R. Holmestad, O. Reiso, and J. Røyset: Behind structure and relation of precipitates in Al–Mg–Si and related alloys: In Proceeding Proceedings of the 12th International Conference on Aluminium Alloys, edited by S. Kumai, O. Umezawa, Y. Takayama, T. Tsuchida, and T. Sato. (Yokohama, Japan); p. 413.

J.P. Lynch, L.M. Brown, and M.H. Jacobs: Microanalysis of age-hardening precipitates in aluminium alloys. Acta Metall. 30, 1389 (1982).

M. Jacobs: The structure of the metastable precipitates formed during ageing of an Al–Mg–Si alloy. Philos. Mag. 26, 1 (1972).

C.D. Marioara, H. Nordmark, S.J. Andersen, and R. Holmestad: Post-β″ phases and their influence on microstructure and hardness in 6xxx Al–Mg–Si alloys. J. Mater. Sci. 41, 471 (2006).

O. Vorren and N. Ryum: Cyclic deformation of Al-single crystals at low constant plastic strain amplitudes. Acta Metall. 35, 855 (1987).

M. Videm and N. Ryum: Cyclic deformation of [001] aluminium single crystals. Mater. Sci. Eng., A 219, 1 (1996).

T. Fujii, N. Sawatari, S. Onaka, and M. Kato: Cyclic deformation of pure aluminum single crystals with double-slip orientations. Mater. Sci. Eng., A 387, 486 (2004).

P. Li, S. Li, Z. Wang, and Z. Zhang: Cyclic deformation behaviors of \(\left[{\bar 579} \right]\)-oriented Al single crystals. Metall. Mater. Trans. A 41, 2532 (2010).

J. Wang, Z.G. Zhu, Q.F. Fang, and G.D. Liu: The influence of the crystallographic orientation on the behavior of fatigue in Al single crystals. Mater. Res. Bull. 34, 407 (1999).

O. Vorren and N. Ryum: Cyclic deformation of Al single crystals: Effect of the crystallographic orientation. Acta Metall. 36, 1443 (1988).

Y.B. Xia: The effect of crystal orientation on mechanical behavior during fatigue in aluminium single crystals. Scr. Metall. 29, 999 (1993).

A. Giese and Y. Estrin: Mechanical behaviour and microstructure of fatigued aluminium single crystals. Scr. Metall. 28, 803 (1993).

T. Zhai, J.W. Martin, and G.A.D. Briggs: Fatigue damage at room temperature in aluminium single crystals—II. TEM. Acta Mater. 44, 1729 (1996).

J. Nellessen, S. Sandlöbes, and D. Raabe: Low cycle fatigue in aluminum single and bi-crystals: On the influence of crystal orientation. Mater. Sci. Eng., A 668, 166 (2016).

T. Zhai, J.W. Martin, G.A.D. Briggs, and A.J. Wilkinson: Fatigue damage at room temperature in aluminium single crystals—III. Lattice rotation. Acta Mater. 44, 3477 (1996).

T. Zhai, J.W. Martin, and G.A.D. Briggs: Fatigue damage in aluminum single crystals—I. On the surface containing the slip burgers vector. Acta Metall. 43, 3813 (1995).

H.D. Chandler and J.V. Bee: Cyclic strain induced precipitation in a solution treated aluminium alloy. Acta Metall. 35, 2503 (1987).

T.S. Srivatsan, S. Sriram, and C. Daniels: Influence of temperature on cyclic stress response and fracture behavior of aluminum alloy 6061. Eng. Fract. Mech. 56, 531 (1997).

D.H. Lee, J.H. Park, and S.W. Nam: Enhancement of mechanical properties of Al–Mg–Si alloys by means of manganese dispersoids. Mater. Sci. Technol. 15, 450 (1999).

P.C. Lam, T.S. Srivatsan, B. Hotton, and M. Al-Hajri: Cyclic stress response characteristics of an aluminum–magnesium–silicon alloy. Mater. Lett. 45, 186 (2000).

L.P. Borrego, L.M. Abreu, J.M. Costa, and J.M. Ferreira: Analysis of low cycle fatigue in AlMgSi aluminium alloys. Eng. Failure Anal. 11, 715 (2004).

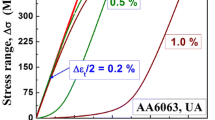

M.M. Yahya, N. Mallik, and I. Chakrabarty: Low cycle fatigue (LCF) behavior of AA6063 aluminium alloy at room temperature. Int. J. Emerging Adv. Res. Technol. 5, 100 (2015).

D. Azzam, C.C. Menzemer, and T.S. Srivatsan: The fracture behavior of an Al–Mg–Si alloy during cyclic fatigue. Mater. Sci. Eng., A 527, 5341 (2010).

X-q. Ding, G-q. He, and C-s. Chen: Study on the dislocation sub-structures of Al–Mg–Si alloys fatigued under non-proportional loadings. J. Mater. Sci. 45, 4046 (2010).

Y. Takahashi, T. Shikama, S. Yoshihara, T. Aiura, and H. Noguchi: Study on dominant mechanism of high-cycle fatigue life in 6061-T6 aluminum alloy through microanalyses of microstructurally small cracks. Acta Mater. 60, 2554 (2012).

S. Nandy, A.P. Sekhar, D. Das, S.J. Hossain, and K.K. Ray: Influence of dynamic precipitation during low cycle fatigue of under-aged AA6063 alloy. Trans. Indian Inst. Met. 69, 319 (2016).

C. Laird, V.J. Langelo, M. Hollrah, N.C. Yang, and R. De La Veaux: The cyclic stress–strain response of precipitation hardened Al–15 wt% Ag alloy. Mater. Sci. Eng. 32, 137 (1978).

R.G. Pahl and J.B. Cohen: Effects of fatigue on the GP zones in Al–Zn alloys. Metall. Mater. Trans. A 15, 1519 (1984).

A. Farrow and C. Laird: Precipitation in solution-treated aluminium–4 wt% copper under cyclic strain. Philos. Mag. 90, 3549 (2010).

W.Z. Han, Y. Chen, A. Vinogradov, and C.R. Hutchinson: Dynamic precipitation during cyclic deformation of an underaged Al–Cu alloy. Mater. Sci. Eng., A 528, 7410 (2011).

M. Hörnqvist and B. Karlsson: Dynamic strain ageing and dynamic precipitation in AA7030 during cyclic deformation. Procedia Eng. 2, 265 (2010).

D.B. Williams and C.B. Carter: The Transmission Electron Microscope (Springer US, New York, 1996).

G. Gottstein: Physical Foundations of Materials Science (Springer Science & Business Media, New York, 2013).

G.E. Dieter and D.J. Bacon: Mechanical Metallurgy (McGraw-Hill, New York, 1986).

A. Deschamps, F. Livet, and Y. Brechet: Influence of predeformation on ageing in an Al–Zn–Mg alloy—I. Microstructure evolution and mechanical properties. Acta Mater. 47, 281 (1998).

A. Deschamps and Y. Brechet: Influence of predeformation and ageing of an Al–Zn–Mg alloy—II. Modeling of precipitation kinetics and yield stress. Acta Mater. 47, 293 (1998).

H.R. Shercliff and M.F. Ashby: A process model for age hardening of aluminium alloys—I. The model. Acta Metall. 38, 1789 (1990).

H.R. Shercliff and M.F. Ashby: A process model for age hardening of aluminium alloys—II. Applications of the model. Acta Metall. 38, 1803 (1990).

S. Esmaeili and D.J. Lloyd: Modeling of precipitation hardening in pre-aged AlMgSi (Cu) alloys. Acta Mater. 53, 5257 (2005).

A. Simar, Y. Brechet, B. De Meester, A. Denquin, and T. Pardoen: Sequential modeling of local precipitation, strength and strain hardening in friction stir welds of an aluminum alloy 6005A-T6. Acta Mater. 55, 6133 (2007).

O. Myhr, Ø. Grong, and S. Andersen: Modelling of the age hardening behaviour of Al–Mg–Si alloys. Acta Mater. 49, 65 (2001).

O.R. Myhr, Ø. Grong, H.G. Fjaer, and C.D. Marioara: Modelling of the microstructure and strength evolution in Al–Mg–Si alloys during multistage thermal processing. Acta Mater. 52, 4997 (2004).

S. Esmaeili, D.J. Lloyd, and W.J. Poole: Modeling of precipitation hardening for the naturally aged Al–Mg–Si–Cu alloy AA6111. Acta Mater. 51, 3467 (2003).

F.X. Mao, C. Bollmann, T. Brüggemann, Z.Q. Liang, H.C. Jiang, and V. Mohles: Modelling of the age-hardening behavior in AA6xxx within a through-process modelling framework: In 15th International Conference on Aluminum Alloys, edited by Q. Liu, J.-F. Nie, R. Sanders, Z. Jia, and L. Cao. (Chongqing, China); p. 640.

F. Delmas, M.J. Casanove, P. Lours, A. Couret, and A. Coujou: Quantitative TEM study of the precipitation microstructure in aluminium alloy Al (MgSiCu) 6056 T6. Mater. Sci. Eng., A 373, 80 (2004).

G. Fribourg, Y. Bréchet, A. Deschamps, and A. Simar: Microstructure-based modelling of isotropic and kinematic strain hardening in a precipitation-hardened aluminium alloy. Acta Mater. 59, 3621 (2011).

Y. Estrin and K. Lücke: Void nucleation in the wake of a moving grain boundary. Scr. Metall. 19, 221 (1985).

A. Deschamps, Y. Brechet, C.J. Necker, S. Saimoto, and J.D. Embury: Study of large strain deformation of dilute solid solutions of Al–Cu using channel-die compression. Mater. Sci. Eng., A 207, 143 (1996).

A. Deschamps, M. Niewczas, F. Bley, Y. Brechet, J.D. Embury, L.L. Sinq, F. Livet, and J.P. Simon: Low-temperature dynamic precipitation in a supersaturated AI–Zn–Mg alloy and related strain hardening. Philos. Mag. A 79, 2485 (1999).

G.W.J. Waldron: A study by transmission electron microscopy of the tensile and fatigue deformation of aluminum–magnesium alloys. Acta Metall. 13, 897 (1965).

H. Mughrabi: Cyclic slip irreversibilities and the evolution of fatigue damage. Metall. Mater. Trans. B 40, 431 (2009).

S.E. Harvey, P.G. Marsh, and W.W. Gerberich: Atomic force microscopy and modeling of fatigue crack initiation in metals. Acta Metall. 42, 3493 (1994).

W.W. Gerberich, S.E. Harvey, D.E. Kramer, and J.W. Hoehn: Low and high cycle fatigue—A continuum supported by AFM observations. Acta Mater. 46, 5007 (1998).

L. Cretegny and A. Saxena: AFM characterization of the evolution of surface deformation during fatigue in polycrystalline copper. Acta Mater. 49, 3755 (2001).

A. Shyam and W.W. Milligan: A model for slip irreversibility, and its effect on the fatigue crack propagation threshold in a nickel-base superalloy. Acta Mater. 53, 835 (2005).

ACKNOWLEDGMENTS

Haichun Jiang gratefully acknowledges funding by the China Scholarship Council (CSC). The authors gratefully acknowledge the Advanced Metals and Processes Cluster (AMAP) and the participating companies Aleris Rolled Products Germany GmbH, Hydro Aluminum Rolled Products GmbH, Novelis Deutschland GmbH for supplying as cold rolled AA6016 sheet material from the AMAP Project P1.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jiang, H., Sandlöbes, S., Gottstein, G. et al. On the effect of precipitates on the cyclic deformation behavior of an Al-Mg-Si alloy. Journal of Materials Research 32, 4398–4410 (2017). https://doi.org/10.1557/jmr.2017.350

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.350