Abstract

The ferritic steel 16Mo3 coated with the nickel-base alloy IN625mod by high-velocity oxy-fuel (HVOF) spraying was investigated under uniaxial and biaxial fatigue loading at 200 and 500 °C. Furthermore, bulk HVOF-sprayed specimens of the coating material IN625mod were also investigated under uniaxial isothermal fatigue loading at 200 and 500 °C. Moreover, the thermo-mechanical fatigue behavior of 16Mo3 was studied under in-phase (IP) and out-of-phase (OP) loading between 200 and 500 °C. The fatigue lives of the bulk coating and the compound material are presented. In particular, the thermo-mechanical OP loading leads to a strong reduction of the lifetimes compared to the IP loading. A conservative estimation of the fatigue lives of the thermo-mechanical loading can be given by isothermal tests at 500 °C. The comparison of the uniaxial loading with the biaxial loading cases shows reasonable coincidence by using the distortion energy hypothesis according to von Mises.

Similar content being viewed by others

References

E. Huttunen-Saarivirta, M. Antonov, R. Veinthal, J. Tuiremo, K. Mkel, and P. Siitonen: Influence of particle impact conditions and temperature on erosionoxidation of steels at elevated temperatures. Wear 272 (1), 159–175 (2011).

F. Ciofu, A. Nioaţă, N. Mihuţ, and C. Rădulescu: The influence of some corrosive environments on the working equipment of the heat exchangers. Fiability & Durability/Fiabilitate si Durabilitate, 1, 46–50 (2014).

M. Rozmus-Górnikowska, M. Blicharski, J. Kusińsk, L. Kuslnski, and M. Marszyck: Influence of boiler pipe cladding techniques on their microstructure and properties. Arch. Metall. Mater. 58 (4), 1093–1096 (2013).

M. Rozmus-Górnikowska, Ł. Cieniek, M. Blicharski, and J. Kusiński: Microstructure and microsegregation of an Inconel 625 weld overlay produced on steel pipes by the cold metal transfer technique. Arch. Metall. Mater. 59 (3), 1081–1084 (2014).

S. Bulatovic, V. Aleksic, and L. Milovic: Failure of steam line causes determined by NDT testing in power and heating plants. Fract. Struct. Integr. 26, 41–48 (2013).

P. Jauhiainen, S. Yli-Olli, A. Nyholm, P. Auerkari, J. Salonen, O. Lehtinen, and S. Mäkinen: Impact of oxidation on creep life of superheaters and reheaters. In Proceedings of the International ECCC Creep Conference, T.A. Shibli and S.R. Holdsworth, eds. (2009); pp. 320–328.

P.P. Psyllaki, G. Pantazopoulos, and H. Lefakis: Metallurgical evaluation of creep-failed superheater tubes. Eng. Failure Anal. 16 (5), 1420–1431 (2009).

H. Ergün, K. Aydinol, T. Öztürk, and M. Doruk: Design of a high temperature erosion apparatus for testing of boiler tubes. Turk. J. Eng. Environ. Sci. 37 (2), 178–185 (2013).

M. Kriegel, O. Fabrichnaya, and H.J. Seifert: Thermodynamische Simulation für Werkstoffe zum Schutz gegen die Dampferzeugerkorrosion. In Dampferzeugerkorrosion, A. Eisenblätter, R. Starke, and T. Zanler, eds. (Saxonia, Freidburg, Germany, 2009); pp. 189–200.

C.W. Lawton: High-temperature low-cycle fatigue: A summary of industry and code work. Exp. Mech. 8 (6), 257–266 (1968).

H. Mayer, H.L. Stark, and S. Ambrose: Review of fatigue design procedures for pressure vessels. Int. J. Pressure Vessels Piping 77 (13), 775–781 (2000).

F. Ellyin and J.D. Wolodko: Testing facilities for multiaxial loading of tubular specimens. ASTM Spec. Tech. Publ. 1280, 7–24 (1997).

L. Bocher, P. Delobelle, P. Robinet, and X. Feaugas: Mechanical and microstructural investigations of an austenitic stainless steel under non-proportional loadings in tension–torsion-internal and external pressure. Int. J. Plast. 17 (11), 1491–1530 (2001).

T. Itoh and Z. Bao: Low cycle fatigue lives under multiaxial non-proportional loading. In Seventh International Conference on Low Cycle Fatigue, T. Beck and E. Charkaluk, eds. (DVM, Berlin, Germany, 2013); pp. 247–252.

V. Bonnand, J.L. Chaboche, P. Gomez, P. Kanouté, and D. Pacou: Investigation of multiaxial fatigue in the context of turboengine disc applications. Int. J. Fatigue 33 (8), 1006–1016 (2011).

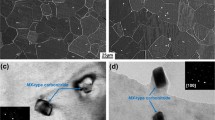

D. Zhang, S.J. Harris, and D.G. McCartney: Microstructure formation and corrosion behaviour in HVOF-sprayed Inconel 625 coatings. Mater. Sci. Eng., A 344 (12), 45–56 (2003).

A.A. Boudi, M.S.J. Hashmi, and B.S. Yilbas: HVOF coating of Inconel 625 onto stainless and carbon steel surfaces: Corrosion and bond testing. J. Mater. Process. Technol. 155–156, 2051–2055 (2004). Proceedings of the International Conference on Advances in Materials and Processing Technologies: Part 2.

H.Y. Al-Fadhli, J. Stokes, M.S.J. Hashmi, and B.S. Yilbas: HVOF coating of welded surfaces: Fatigue and corrosion behaviour of stainless steel coated with Inconel-625 alloy. Surf. Coat. Technol. 200 (16–17), 4904–4908 (2006).

H.Y. Al-Fadhli, J. Stokes, M.S.J. Hashmi, and B.S. Yilbas: The erosion corrosion behaviour of high velocity oxy-fuel (HVOF) thermally sprayed Inconel-625 coatings on different metallic surfaces. Surf. Coat. Technol. 200 (20–21), 5782–5788 (2006).

N. Ahmed, M.S. Bakare, D.G. McCartney, and K.T. Voisey: The effects of microstructural features on the performance gap in corrosion resistance between bulk and HVOF sprayed Inconel 625. Surf. Coat. Technol. 204 (14), 2294–2301 (2010).

A.A. Boudi, M.S.J. Hashmi, and B.S. Yilbas: ESEM evaluation of Inconel-625 thermal spray coating (HVOF) onto stainless steel and carbon steel post brine exposure after tensile tests. J. Mater. Process. Technol. 173 (1), 44–52 (2006).

R.G. Bonora, H.J.C. Voorwald, M.O.H. Cioffi, G.S. Junior, and L.F.V. Santos: Fatigue in AISI 4340 steel thermal spray coating by HVOF for aeronautic application. Procedia Eng. 2 (1), 1617–1623 (2010).

E.S. Puchi Cabrera, J.A. Berrios-Ortiz, J. Da-Silva, and J. Nunes: Fatigue behavior of a 4140 steel coated with a Colmonoy 88 alloy applied by HVOF. Surf. Coat. Technol. 172 (23), 128–138 (2003).

E.S. Puchi-Cabrera, M.H. Staia, J. Lesage, D. Chicot, J.G. La Barbera-Sosa, and E.A. Ochoa-Prez: Fatigue performance of a SAE 1045 steel coated with a Colmonoy 88 alloy deposited by HVOF thermal spraying. Surf. Coat. Technol. 201 (5), 2038–2045 (2006).

E.S. Puchi-Cabrera, M.H. Staia, M.J. Ortiz-Mancilla, J.G. La Barbera-Sosa, E.A. Ochoa Prez, C. Villalobos-Gutirrez, S. Bellayer, M. Traisnel, D. Chicot, and J. Lesage: Fatigue behavior of a SAE 1045 steel coated with Colmonoy 88 alloy deposited by HVOF thermal spray. Surf. Coat. Technol. 205 (4), 1119–1126 (2010). Proceedings of the fourth workshop RIPT (Les Rencontres Internationales sur la Projection Thermique) and the third workshop on Suspension and Solution Thermal Spraying (S2TS).

K. Padilla, A. Velsquez, J.A. Berrios, and E.S. Puchi Cabrera: Fatigue behavior of a 4140 steel coated with a NiMoAl deposit applied by HVOF thermal spray. Surf. Coat. Technol. 150 (2–3), 151–162 (2002).

R.C. Souza, H.J.C. Voorwald, and M.O.H. Cioffi: Fatigue strength of HVOF sprayed Cr3C2–25NiCr and WC–10Ni on AISI 4340 steel. Surf. Coat. Technol. 203 (3–4), 191–198 (2008).

R. Kowalewski and H. Mughrabi: Influence of a plasma-sprayed NiCrAlY coating on the low-cycle fatigue behaviour of a directionally solidified nickel-base superalloy. Mater. Sci. Eng., A 247 (1–2), 295–299 (1998).

F. Grube, E.E. Affeldt, and H. Mughrabi: Thermomechanical fatigue behavior of an aluminide-coated monocrystalline Ni-base superalloy. In Thermomechanical Fatigue Behavior of Materials, Vol. 4 (ASTM International, 2003); pp. 164–179.

Y.C. Zhou and T. Hashida: Thermal fatigue failure induced by delamination in thermal barrier coating. Int. J. Fatigue 24 (2–4), 407–417 (2002).

Z.B. Chen, Z.W. Huang, Z.G. Wang, and S.J. Zhu: Failure behavior of coated nickel-based superalloy under thermomechanical fatigue. J. Mater. Sci. 44 (23), 6251–6257 (2009).

Z.B. Chen, Z.G. Wang, and S.J. Zhu: Thermomechanical fatigue behavior of an air plasma sprayed thermal barrier coating system. Mater. Sci. Eng., A 528 (29–30), 8396–8401 (2011).

C. Giolli, A. Scrivani, G. Rizzi, F. Borgioli, G. Bolelli, and L. Lusvarghi: Failure mechanism for thermal fatigue of thermal barrier coating systems. J. Therm. Spray Technol. 18 (2), 223–230 (2009).

T. Sadowski and P. Golewski: Cracks path growth in turbine blades with TBC under thermo-mechanical cyclic loadings. Fract. Integr. Struct. 35, 492–499 (2016).

S. Stekovic: Low cycle fatigue and thermo-mechanical fatigue of uncoated and coated nickel-base superalloys. Ph.D. thesis, Institutionen för ekonomisk och industriell utveckling, 2007.

H. Brodin, M. Jinnestrand, S. Johansson, and S. Sjöström: Thermal Barrier Coating Fatigue Life Assessment; Technical Report; Siemens AG, 2006.

R. Nützel, E. Affeldt, and M. Göken: Damage evolution during thermo-mechanical fatigue of a coated monocrystalline nickel-base superalloy. Int. J. Fatigue 30 (2), 313–317 (2008).

E. Fleury and J.S. Ha: Thermomechanical fatigue behaviour of nickel base superalloy IN738LC part 2—Lifetime prediction. Mater. Sci. Technol. 17 (9), 1087–1092 (2001).

Z.W. Huang, Z.G. Wang, S.J. Zhu, F.H. Yuan, and F.G. Wang: Effect of HVOF sprayed MCrAlY coating on thermomechanical and isothermal fatigue life of superalloy M963. In Key Engineering Materials, Vol. 373 (Trans Tech Publications, 2008); pp. 23–26.

M. Okazaki: High-temperature strength of Ni-base superalloy coatings. Sci. Technol. Adv. Mater. 2 (2), 357–366 (2001).

M. Hoffmann and H. Biermann: Static and cyclic deformation behavior of the ferritic steel 16Mo3 under monotonic and cyclic loading at high temperatures. Steel Res. Int. 83 (7), 631–636 (2012).

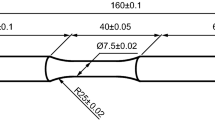

D. Kulawinski, M. Hoffmann, T. Lippmann, G. Lamprecht, S. Henkel, and H. Biermann: Fatigue behavior of 16Mo3 at elevated temperatures under uniaxial as well as biaxial-planar loading. Fatigue Fract. Eng. Mater. Struct. (2016).

S. Soltysiak, M. Selent, S. Roth, M. Abendroth, M. Hoffmann, H. Biermann, and M. Kuna: High-temperature small punch test for mechanical characterization of a nickel-base super alloy. Mater. Sci. Eng., A 614, 259–263 (2014).

M. Selent, S. Soltysiak, S. Roth, M. Abendroth, M. Hoffmann, and M. Kuna: Mechanical characterisation of a thermally sprayed nickel-base superalloy by means of the high temperature small punch test. In 3rd International Conference SSTT (Small Sample Test Techniques) (2014); pp. 98–111.

H.C.M. Andersson and E. Sjöström: Thermal gradients in round tmf specimens. Int. J. Fatigue 30 (2), 391–396 (2008).

T. Beck, P. Hähner, H-J. Kühn, C. Rae, E.E. Affeldt, H. Andersson, A. Köster, and M. Marchionni: Thermo-mechanical fatigue—The route to standardisation (“TMF-standard” project). Mater. Corros. 57 (1), 53–59 (2006).

P. Hähner, E. Affeldt, T. Beck, H. Klingelhöffer, M. Loveday, and C. Rinaldi: Validated Code-of-Practice for Strain-Controlled Thermo-Mechanical Fatigue Testing; EC-Report EUR 22281 EN (2006).

P. Hähner, C. Rinaldi, V. Bicego, E. Affeldt, T. Brendel, H. Andersson, T. Beck, H. Klingelhöffer, H.J. Kühn, A. Köster, M. Loveday, M. Marchionni, and C. Rae: Research and development into a european code-of-practice for strain-controlled thermo-mechanical fatigue testing. Int. J. Fatigue 30 (2), 372–381 (2008).

D. Kulawinski, A. Weidner, S. Henkel, and H. Biermann: Isothermal and thermo-mechanical fatigue behavior of the nickel base superalloy waspaloy under uniaxial and biaxial-planar loading. Int. J. Fatigue 81, 21–36 (2015).

D. Kulawinski, S. Henkel, D. Holländer, M. Thiele, U. Gampe, and H. Biermann: Fatigue behavior of the nickel-base superalloy Waspaloy under proportional biaxial-planar loading at high temperature. Int. J. Fatigue 67, 212–219 (2014).

K. Pascoe and J. Villiers: Low cycle fatigue of steels under biaxial straining. J. Strain Anal. Eng. 2 (2), 117–126 (1967).

D. Kulawinski, K. Nagel, S. Henkel, P. Hübner, H. Fischer, M. Kuna, and H. Biermann: Characterization of stress–strain behavior of a cast TRIP steel under different biaxial planar load ratios. Eng. Fract. Mech. 78 (8), 1684–1695 (2011).

D. Kulawinski, S. Ackermann, A. Seupel, T. Lippmann, S. Henkel, M. Kuna, A. Weidner, and H. Biermann: Deformation and strain hardening behavior of powder metallurgical TRIP steel under quasi-static biaxial-planar loading. Mater. Sci. Eng., A 642, 317–329 (2015).

D. Kulawinski, S. Ackermann, A. Glage, S. Henkel, and H. Biermann: Biaxial low cycle fatigue behavior and martensite formation of a metastable austenitic cast TRIP steel under proportional loading. Steel Res. Int. 82 (9), 1141–1148 (2011).

D. Kulawinski: Biaxial-planare isotherme und thermo-mechanische Ermüdung an polykristallinen Nickelbasis-Superlegierungen. Ph.D. thesis, TU Bergakademie Freiberg, Berlin, Germany, 2015.

J.A. Bannantine, J.J. Comer, and J.L. Handrock: Fundamentals of Metal Fatigue Analysis (Prentice Hall, Uppder Saddle River, New Jersey, 1989).

C.M. Sonsino and V. Grubisic: Kurzzeitschwingfestigkeit von duktilen Stählen unter mehrachsiger Beanspruchung. Materialwiss. Werkstofftech. 15, 378–386 (1984).

P. Mukherjee, A. Sarkar, P. Barat, T. Jayakumar, S. Mahadevan, and S.K. Rai: Lattice misfit measurement in Inconel 625 by X-ray diffraction technique. arXiv preprint cond-mat/0604222 (2006).

K. Kusabiraki, H. Komatsu, and S. Ikeuchi: Lattice constants and compositions of the metastable Ni3Nb phase precipitated in a Ni–15Cr–8Fe–6Nb alloy. Metall. Mater. Trans. A 29 (4), 1169–1174 (1998).

B. Reppich: Negatives kriechen. Z. Metallkd. 75, 193–202 (1984).

D.J. Wilson and A. Ferrari: Time-dependent Edge Notch Sensitivity of Oxide and Gamma Prime Dispersion Strengthened Sheet Materials at 1000° to 1800 °F (538–982 °C); Technical Report; The University of Michigan, 1972.

M.W. Brown and K.J. Miller: High temperature low cycle biaxial fatigue of two steels. Fatigue Fract. Eng. Mater. Struct. 1 (2), 217–229 (1979).

T. Itoh, M. Sakane, and M. Ohnami: High temperature multiaxial low cycle fatigue of cruciform specimen. J. Eng. Mater. Technol. 116, 90–98 (1994).

P. Wang, L. Cui, M. Lyschik, A. Scholz, C. Berger, and M. Oechsner: A local extrapolation based calculation reduction method for the application of constitutive material models for creep fatigue assessment. Int. J. Fatigue 44, 253–259 (2012).

P. Wang, L. Cui, A. Scholz, S. Linn, and M. Oechsner: Multiaxial thermomechanical creep-fatigue analysis of heat-resistant steels with varying chromium contents. Int. J. Fatigue 67, 220–227 (2014).

T. Łagoda, E. Macha, and M. Sakane: Estimation of high temperature fatigue lifetime of SUS304 steel with an energy parameter in the critical plane. J. Theor. Appl. Mech. 41, 55–73 (2003).

M. Sakane, M. Ohnami, T. Kuno, and T. Itsumura: High temperature biaxial low cycle fatigue using cruciform specimen. J. Soc. Mater. Sci., Jpn. 37 (414), 340–346 (1987).

T. Ogata and Y. Takahashi: Development of a high-temperature biaxial fatigue testing machine using a cruciform specimen. In Multiaxial Fatigue and Fracture Fifth International Conference on Biaxial/Multiaxial Fatigue and Fracture, W. Bedkowski, E. Macha, and T. Łagoda, eds.; European Structural Integrity Society, Vol. 25 (Elsevier, 1999); pp. 101–114.

T. Ogata: Biaxial thermomechanical-fatigue life property of a directionally solidified Ni-base superalloy. J. Eng. Gas Turbines Power 130 (6), 062101 (2008).

ACKNOWLEDGMENTS

The authors acknowledge the financial support of the European Union (European Fund for Regional Development) and the Free State of Saxony within Saxon Excellence Initiative ADDE (ADDE under funding grant in the subproject TP 15 No. 13852/2337). A special thank goes to Professor M. Sakane, Ritsumeikan University, Kyoto, Japan, for the helpful remarks as well as the discussion. Furthermore, we want to thank Dipl.-Ing. R. Kolmorgen for experimental support.

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Kulawinski, D., Hoffmann, M., Lippmann, T. et al. Isothermal and thermo-mechanical fatigue behavior of 16Mo3 steel coated with high-velocity oxy-fuel sprayed nickel-base alloy under uniaxial as well as biaxial-planar loading. Journal of Materials Research 32, 4411–4423 (2017). https://doi.org/10.1557/jmr.2017.344

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.344