Abstract

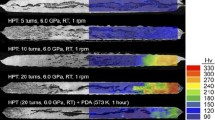

A modification of the metal processing technique known as equal channel angular pressing (ECAP) to incorporate shear plane rotation, called ECAP-R, is presented. The new process was developed to produce hybrid materials with helical architecture of their constituents, which holds promise to enable enhanced mechanical properties. The process was trialled experimentally using a specially designed laboratory-scale rig. It was shown that a positive mean stress (negative hydrostatic pressure) in a part of the multipiece billet leads to separation of the constituents within that region. A way to improving the process design was suggested based on finite element simulations. It was demonstrated that the proposed processing results in excellent bonding between the helical parts of the hybrid in the regions of positive hydrostatic pressure. Subsequent annealing gave rise to further improvement of the quality of bonding. Processing by ECAP-R at elevated temperatures was suggested as a viable method of producing hybrid materials with helical architecture.

Similar content being viewed by others

References

M.F. Ashby: Hybrids to fill holes in material property space. Philos. Mag. 85, 3235 (2005).

M.F. Ashby and Y.J.M. Bréchet: Designing hybrid materials. Acta Mater. 51 (19), 5801 (2003).

O. Bouaziz, Y. Brechet, and J.D. Embury: Heterogeneous and architectured materials: A possible strategy for design of structural materials. Adv. Eng. Mater. 10, 21 (2008).

J.D. Embury and O. Bouaziz: Steel-based composites. Annu. Rev. Mater. Res. 40, 213 (2010).

O. Bouaziz, H.S. Kim, and Y. Estrin: Architecturing of metal-based composites with concurrent nanostructuring: A new paradigm of materials design. Adv. Eng. Mater. 15, 336 (2013).

R.Z. Valiev, M.J. Zehetbauer, Y. Estrin, H.W. Hoppel, Y. Ivanisenko, H. Hahn, G. Wilde, H.J. Roven, X. Sauvage, and T.G. Langdon: The innovation potential of bulk nanostructured materials. Adv. Eng. Mater. 9 (7), 527 (2007).

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zechetbauer, and Y.T. Zhu: Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58, 33 (2006).

A. Bachmaier and R. Pippan: Generation of metallic nanocomposites by severe plastic deformation. Int. Mater. Rev. 58 (1), 41 (2013).

D. Raabe, P-P. Choi, Y. Li, A. Kostka, X. Sauvage, F. Lecouturier, K. Hono, R. Kirchheim, R. Pippan, and D. Embury: Metallic composites processed via extreme deformation: Toward the limits of strength in bulk materials. MRS Bull. 35, 982 (2010).

R. Lapovok, Y. Qi, H.P. Ng, V. Maier, and Y. Estrin: Multicomponent materials from machining chips compacted by equal-channel angular pressing. J. Mater. Sci. 49 (3), 1193 (2014).

Y. Beygelzimer, Y. Estrin, and R. Kulagin: Synthesis of hybrid materials by severe plastic deformation: A new paradigm of SPD processing. Adv. Eng. Mater. 17, 1853 (2015).

S.A. Wainright, W.D. Biggs, J.D. Currey, and J.M. Gosline: Mechanical Design in Organisms (Edward Arnold Publishers, London, 1976).

D. Fengel and G. Wegener: Wood-Chemistry (De Gruyter, Berlin, 1984).

T. Zhang, Y. Ma, K. Chen, M. Kunz, N. Tamura, M. Qiang, J. Xu, and L. Qi: Structure and mechanical: Properties of a pteropod shell consisting of interlocked helical aragonite nanofibers. Angew. Chem., Int. Ed. 50 (44), 10361 (2011).

O. Bouaziz, S. Allain, D. Barcelo, and R. Niang: Strengthening by plastic corrugated reinforcements: An effective way for strain-hardening improvement by architecture. In Architectured Multifunctional Materials, Y.J.M. Brechet, J.D. Embury, and P.R. Onck, eds. (Materials Research Society Symposia Proceedings 1188, San Francisco, USA, 2009), pp. 111–115.

S. Khoddam, Y. Estrin, H.S. Kim, and O. Bouaziz: Torsional and compressive behaviours of a hybrid material: Spiral fibre reinforced metal matrix composite. Mater. Des. 85, 404 (2015).

M.I. Latypov, Y. Beygelzimer, R. Kulagin, V. Varyukhin, and H.S. Kim: Toward architecturing of metal composites by twist extrusion. Mater. Res. Lett. 3, 161 (2015).

Y. Beygelzimer, R. Kulagin, and Y. Estrin: Severe plastic deformation as a way to produce architectured materials. In Architectured Materials, Y. Estrin, J. Dunlop, Y. Brechet, P. Fratzl, R. Dendievel, eds. (Springer, Heidelberg, Germany). (in press).

Available at: http://www.qform3d.com/products/qform.

R. Lapovok: The role of back-pressure in equal channel angular extrusion. J. Mater. Sci. 40 (2), 341 (2005).

P.J. Blau: Friction Science and Technology: From Concepts to Applications (CRC Press, Boca Raton, Florida, 2008).

E. Hug and N. Bellido: Brittleness study of intermetallic (Cu, Al) layers in copper-clad aluminium thin wires. J. Mater. Sci. Eng. A 528, 7103 (2011).

ACKNOWLEDGMENTS

One of the authors (YE) acknowledges financial support from the Russian Ministry of Education and Science through grant #14.A12.31.0001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lapovok, R., Molotnikov, A., Medvedev, A. et al. Equal channel angular pressing with rotating shear plane to produce hybrid materials with helical architecture of constituents. Journal of Materials Research 32, 4483–4490 (2017). https://doi.org/10.1557/jmr.2017.339

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.339